Rubber Bulb Trim Seals

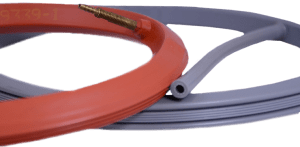

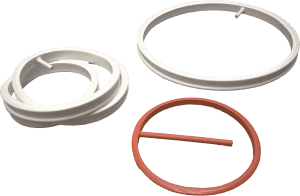

Bulb trim are dual durometer rubber seals with separate bulb and retainer sections. Typically, the bulb is made of a medium-density foam or sponge rubber such as EPDM. The retainer or trim portion is often made of another rubber material, such as PVC. Because of their design and materials of construction, bulb seals and trim seals offer resistance to water, ozone, sunlight, and a range of service temperatures.

EC28-100-EM

EC28-100-EM

More InformationEC28-112-EM

EC28-112-EM

More InformationEC28-200-EM

EC28-200-EM

More InformationEC28-201-EM

EC28-201-EM

More InformationEC28-204-EM

EC28-204-EM

More InformationEC28-208-EM

EC28-208-EM

More InformationEC28-210-EM

EC28-210-EM

More InformationEC28-212-EM

EC28-212-EM

More InformationEC28-213-EM

EC28-213-EM

More InformationEC28-215-EM

EC28-215-EM

More InformationEC28-220-EM

EC28-220-EM

More InformationEC28-222-EM

EC28-222-EM

More InformationEC28-230-EM

EC28-230-EM

More InformationEC28-240-EM

EC28-240-EM

More InformationEC28-250-EM

EC28-250-EM

More InformationEC28-260-EM

EC28-260-EM

More InformationEC28-270-EM

EC28-270-EM

More InformationEC28-271-EM

EC28-271-EM

More InformationEC28-274-EM

EC28-274-EM

More InformationEC28-280-EM

EC28-280-EM

More InformationEC28-290-EM

EC28-290-EM

More InformationEC28-315-EM

EC28-315-EM

More InformationEC28-320-EM

EC28-320-EM

More InformationEC28-405-EM

EC28-405-EM

More InformationEC28-410-EM

EC28-410-EM

More InformationEC28-415-EM

EC28-415-EM

More InformationEC28-420-EM

EC28-420-EM

More InformationEC28-503-EM

EC28-503-EM

More InformationEC28-511-EM

EC28-511-EM

More InformationEC28-975-EM

EC28-975-EM

More InformationRubber Bulb Trim Seals: Specifications

Bulb trim is specified according to seal dimensions and weight, durometer and shape, and rubber compound. Depending upon the application and industry, parameters such as temperature range, flammability, and code compliance may be important to consider. Most bulb trim is black, but industrial rubber products in different colors are available.

Bulb trim seals typically have four difference measurements: A, B, C, D, and E. Durometer, a measure of hardness, is given in Shore A. Bulb trim seals also vary in terms of shape and bulb location. Bulbs vary in size and typically have an inch-based inner diameter (ID) and outer diameter (OD).

Rubber Bulb Trim Seals: Types

Some bulbs use 80-durometer rubber, but most feature medium-density EPDM, a closed-cell sponge material that resists moisture and withstands temperature extremes. EPDM also provides a relatively high degree of electrical insulation. Unlike many elastomers, EPDM exhibits superior UV resistance, making EPDM bulb trim a good choice for outdoor applications.

Bulb trim seals are also available in thermoplastic elastomers (TPEs) or thermoplastic rubber (TPR), polymers that have both thermoplastic and rubber-like (elastomeric) properties. TPEs and TPRs are weather-resistant, reusable, and recyclable. They will repeatedly soften when heated and stiffen when cooled.

Thermoplastic rubbers are more expensive than other compounds but offer advantages over popular plastics such as polyvinyl chloride (PVC). Because it’s flexible and pliable, TPE is less likely to break – especially in cold temperatures. Thermoplastic elastomers also offer good shape memory and lower thermal conductivity.