Water Jet Cutting Services

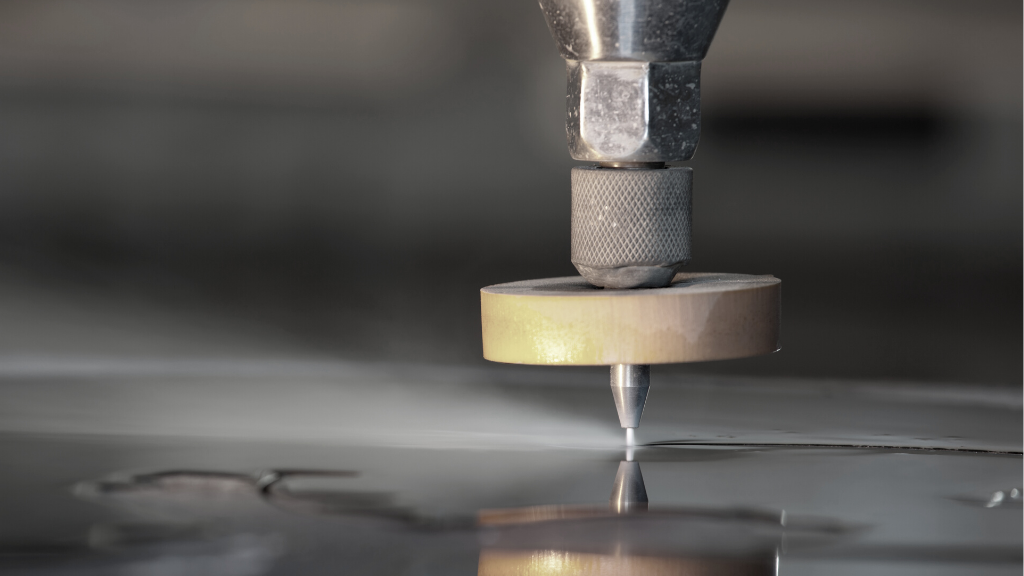

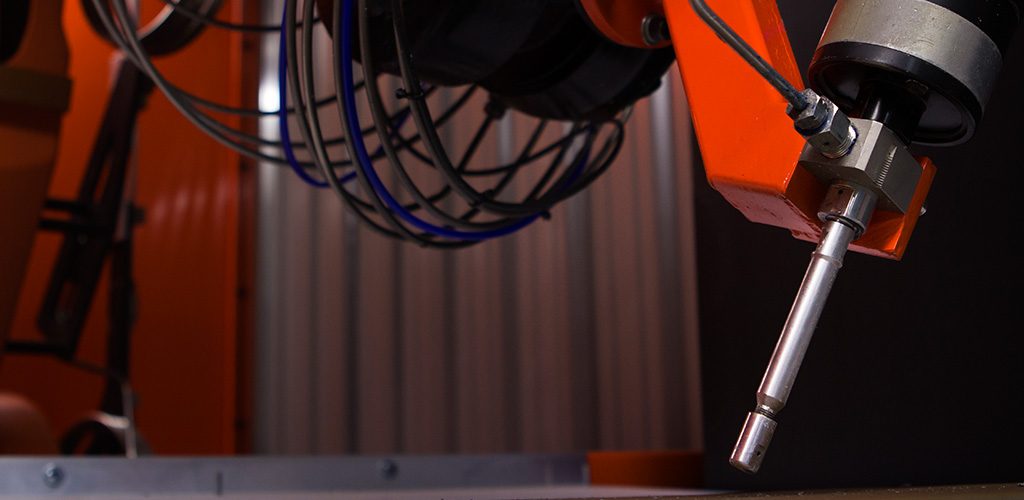

Waterjet cutting uses a highly pressurized stream of water to convert materials and fabricate parts with speed and precision. The equipment is computer-controlled and includes both gantry-style tables and multi-axis robots.

There are two main types of waterjet cutting.

- Pure waterjet cutting is used with softer and thinner materials. The highly-pressurized stream of water does not contain an abrasive material.

- Abrasive waterjet cutting is used with harder and thicker materials. The stream of water includes garnet abrasive for additional cutting power.

Water Jet Cutting Near Greenville, South Carolina (Atlanta and Charlotte)

Elasto Proxy USA provides pure water jet cutting services to customers in the Southeastern U.S. and beyond. Our Simpsonville, South Carolina facility is a just a few hours’ drive from Atlanta, Georgia and Charlotte, North Carolina.

- The gantry-style machine has a generous 7′ x 14′ table for larger parts.

- Cuts rubber, plastic, wood, foam, and other softer materials.

Water Jet Cutting Near Montreal, Canada

Elasto Proxy’s headquarters near Montreal, Canada provides both pure water jet cutting and abrasive water jet cutting services.

- Elasto Proxy has two pure water jet cutting machines at our Boisbriand, Quebec headquarters.

- Both are gantry-style machines with generous cutting tables and the ability to cut either large or small parts.

- One of these machines can make fine, fast cuts as small as 1/2” x 1/2” (12.7 mm x 12.7 mm) and with holes that have diameters as small as 0.01” (0.254 mm).

- Elasto Proxy has two abrasive water jet cutting machines at our Montreal-area facility.

- The first is a three-axis gantry-style machine.

- The second is a robotic six-axis abrasive water jet cutter that uses an ABB IRB-4400 industrial robot.

How Pure Water Jet Cutting Works

Pure water jet cutting uses a stream of highly-pressurized water to provide the cutting action. First, a pump generates pressures measured in tens of thousands of pounds. To put this in perspective, a fire hose delivers water at a pressure that is less than 1000 pounds per square inch. Next, the water jet cutter converts this pressure into velocity. Water travels into cutting heads and a jewel orifice restricts the flow as high-pressure water cuts rubber sheet materials or extrusions.

Advantages of Pure Water Jet Cutting

- No tooling to pay for or wait for

- Faster setup times because there’s no clamping or fixturing

- Quick-turn prototyping and low-to-medium production volumes

- Fine, fast cuts in a wide range of sizes

- Parts nesting and the ability to cut multiple sheets at a time

- No workpiece distortion, warping, or heat-effected areas

- Smooth joints and clean edges that are easier to bond

- Dovetail cuts, chamfered edges, and 90° corners

- Rubber, plastics, and thermal and acoustic foams

How Abrasive Water Jet Cutting Works

Abrasive water jetting mixes garnet abrasive with a high-pressure, high-velocity stream of water to cut cleanly through harder materials. Depending on the material and thickness, abrasive water jetting can achieve accuracies measured in tenths of a millimeter. This cutting technique can produce intricate cuts, 3D shapes, and near-net shapes with excellent edge quality.

Advantages of Abrasive Water Jet Cutting

- No tooling to pay for or wait for

- Faster setup times because there’s no clamping or fixturing

- Quick-turn prototyping and low-to-medium production volumes

- Fine, fast cuts in a range of sizes with support for part nesting

- No workpiece distortion, warping, or heat-effected areas

- Smooth joints and clean edges that are easier to bond

- Dovetail cuts, chamfered edges, and 90° corners

- Hard materials; thick, soft materials; rubber with metal wires

Three-Axis Abrasive Water Jet Cutting

Elasto Proxy’s three-axis abrasive water jet cutter at our Montreal-area headquarters is an OMAX 2652 with the following specifications.

- X-Y cutting envelope of 52” x 26” (1320.8 mm x 660.4 mm)

- Z-axis travel of 8” (203.2 mm)

- table size of 69” L x 30” W (1752.6 mm x 762 mm)

- minimum feature sizes of 3/8” (9.525 mm), including angles and circles.

With aluminum, tolerances of 1/8” (3.175 mm) are typical.

Six-Axis Abrasive Water Jet Cutting

Elasto Proxy six-axis abrasive water jet cutter at our Montreal-area headquarters has a working environment of 40” x 60” and has an articulated arm with rotary joints that combine freedom of movement with dexterity. As the table below explains, these six degrees of freedom (DOF) supports movement anywhere in the work envelope.

Axis | Description |

1 | Rotates the robot |

2 | Forward and backwards extension of the robot’s lower arm |

3 | Raises and lowers the robot’s upper arm |

4 | Rotates the robot’s upper arm (wrist roll) |

5 | Raises and lowers the wrist of the robot’s arm |

6 | Rotates the wrist of the robot’s arm |

Six-axis robots like our ABB IRB-4400 can perform a wider variety of operations than robots with fewer axes. These operations, or motions, control the actions of the end effector – the device or tool that’s connected to the robot’s arm. In the case of abrasive water jet cutting, the tool is a nozzle that directs the high-pressure, high-velocity stream that provides the cutting action.

In addition to harder materials, applications include fast, precise, and cost-effective cuts like 45° angles on reinforced bulb trim. Six-axis robotic abrasive water jet cutting is also used with reinforced edge trim.

Water Jet Cutting vs. Other Forms of Cutting

Water jet cutting provides advantages over these and other cutting processes.

- Manual cutting

- Guillotine cutting

- Digital knife cutting

- Die cutting

- CNC cutting

- Laser cutting

The following sections explain.

Manual Cutting and Guillotine Cutting

Manual cutting is the simplest cutting method for rubber and plastic materials. Typically, a box cutter or bladed knife is used. A worker positions a sheet or profile on a flat surface and uses a template to cut the part. Over time, however, the edges of the template are cut away and the cut parts lack the proper dimensions. Manual cutting also poses a risk of hand injuries, and miscuts that result in material waste.

Guillotine cutting uses a small, manually-directed machine that cuts horizontally or vertically from edge to edge. Like manual cutting, guillotine cutting can deform rubber profiles and produce cuts with inconsistent quality. It also creates a beveled edge that is difficult to bond. With guillotine cutting, surface finishing may be required.

Digital Knife Cutting and Die Cutting

Digital knife cutting requires customers to buy a set of knives or pay for the use of existing tooling. Die cutting requires part-specific tools called dies. Metal dies vary in terms of cost and precision, and complex dies take longer to machine. Die cutting is cost-effective across high volumes of parts, but not for prototypes or lower production volumes. It also puts pressure on the profile and can cause beveling and edge distortions, especially with softer elastomers.

CNC Cutting and Laser Cutting

CNC cutting requires tooling and, like laser cutting, can cause warping or distortion. Laser cutting also creates heat-effected zones and can cause material hardening. Vapors, smoke, and dust require air filtration. Water jet equipment traps these contaminants in the water, which is filtered and can be reused. Any heat that’s produced is cooled by the water stream.

Water Jet Cut Materials

This is a list of some of the materials that we can cut for you.

Acoustic Foams | Brass and Copper | Kevlar | Steel |

Aluminum | Carbon Fiber | Plastic | Thermal Foams |

Ballistic Glass | Fiberglass | Rubber | Titanium |

Ballistic Steel | Garlock® | Stainless Steel | Challenge Us! |

Download the Ultimate Customer Success Guide. It is FREE!

Discover more about Elasto Proxy’s customer success and industry standards in the guide.