Silicone Hose Connectors

HC-222-S

HC-222-S

More InformationHC-404-S

HC-404-S

More InformationHC-21571-EI

HC-21571-EI

More InformationHC-24717-NI

HC-24717-NI

More InformationHC-030035A060-SR

HC-030035A060-SR

More InformationHC-035035A068-SR

HC-035035A068-SR

More InformationCustom Silicone Connectors: The Ultimate Guide

Custom silicone connectors can be molded, wrapped or formed rubber parts that connect the intake pipes and tubes in diesel-powered heavy equipment and in the transportation industry. Different materials can be layered from the inside diameter (OD) to the outside diameter (OD). Regardless of the manufacturing process, custom silicone connectors can withstand high temperatures and provide strength and flexibility. Types of products include custom silicone elbows and custom silicone hoses.

Custom silicone couplers, as this group of rubber products is also known, can meet specific pressure ratings and industry standards. Products are specified by bend radius, reinforcement, and liner materials. Custom silicone hose connectors and tube connectors also come in different ply configurations with or without convolutions. Elasto Proxy can also mark your custom hose connectors with part numbers or your company’s logo.

Elasto Proxy supplies the heavy equipment and transportation industries with many types of custom silicone connectors. Use our “Ultimate Guide” to learn about:

- Product Types

- Specifications

- MTAP (Media, Temperature, Application and Pressure)

The following sections explain. If you need custom silicones, click the button below to send a message to our solutions providers.

Types of Custom Silicone Connectors

Whether you need a custom heater hose, a custom coolant hose, or a custom silicone elbow up to 180°, Elasto Proxy can supply what you need. This part of the “Ultimate Guide” describes these product categories.

- silicone elbows

- silicone reducer hoses

- straight silicone hoses

- hump hoses

- wrapped hoses

- other custom silicone hose connectors

Keep reading to learn more.

Custom Silicone Elbows

Custom silicone elbows contain a molded bend (the elbow) and provide excellent flexibility. Typically, the angle of the bend is either 45° or 90°. Dimensional specifications include wall thickness, inside diameter, inside radius, and the lengths of legs 1 and 2. Custom silicone elbows come in ply configurations that can meet your flexibility and burst requirements. Examples include 4 ply silicone polyester-reinforced elbows with a 45° bend and aramid-reinforced 90° high-temperature elbows for elevated engine bay temperatures.

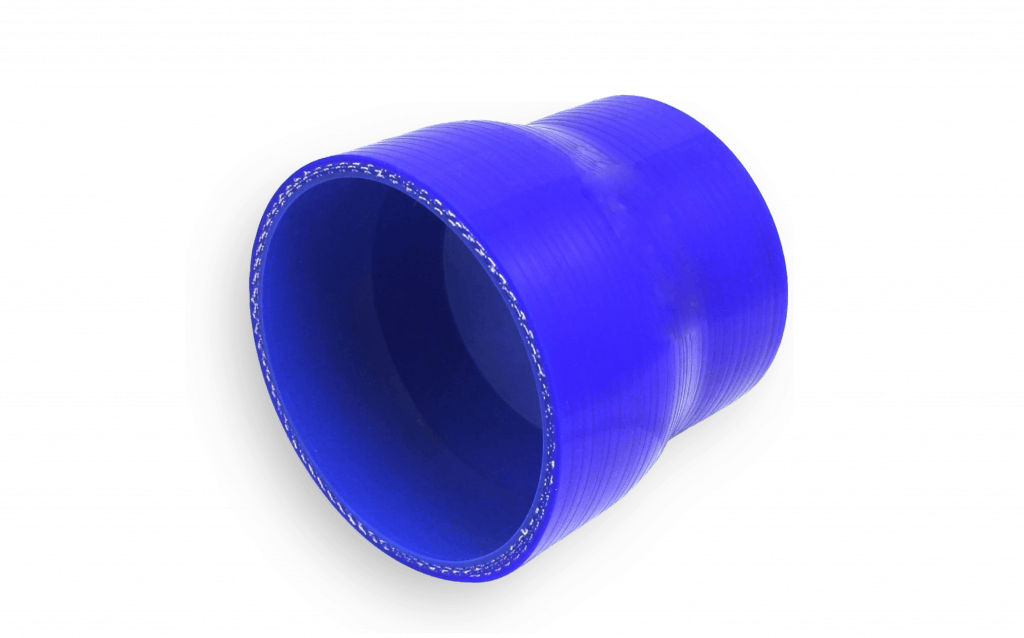

Custom Silicone Reducer Hoses

Custom silicone reducer hoses or custom silicone reducers provide for a transition between different sizes of engine pipes or tubes. Consequently, one end of the reducer is larger than the other. Dimensional specifications include hose inside diameter (ID), hose outside diameter (OD), and length. Applications include connecting different sizes of intercooler, turbocharger, supercharger, and intake components. Reducer hoses are also used to join the intake pipe to a throttle body assembly, an air metering assembly, or custom compressor.

Custom Straight Silicone Hoses

Custom straight silicone hoses come in different lengths and can be cut-to-size at your facility or with Elasto Proxy’s custom fabrication services. They support the use of metal clamps and may contain fabric reinforcements. Custom straight silicone hoses include coolant hoses, heater hoses, and charged air or CAC hoses for either the hot side or cold side of an engine. Some CAC hoses have a 4 ply silicone aramid-reinforced style and feature stainless steel restraining rings that reduce swell and increase hoop strength.

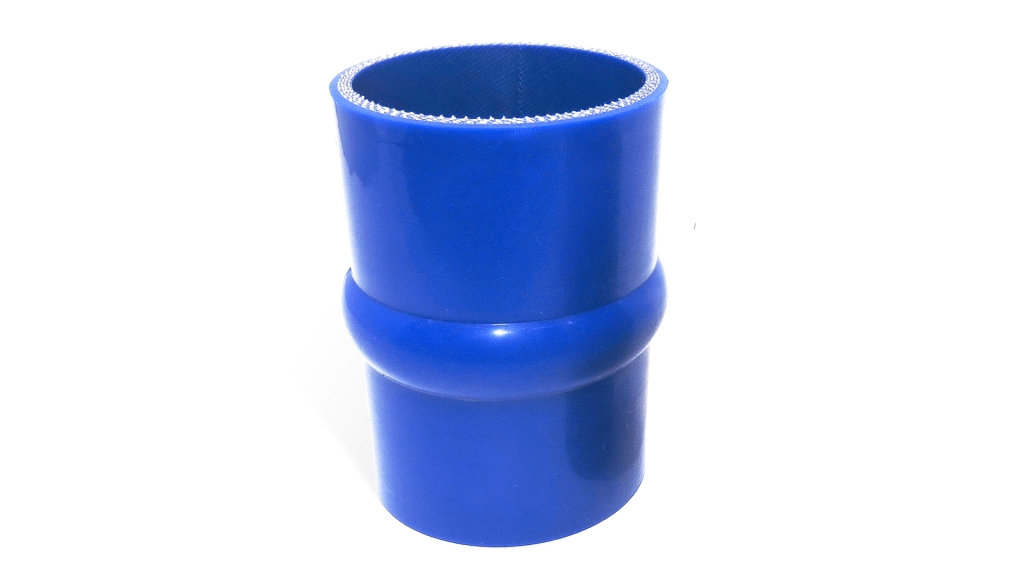

Custom Silicone Hump Hoses

Custom silicone hump hoses support slight intake adjustments and bends on the hot side or cold side of an engine. They also compensate for minor misalignments between metal pipes or tubes. Aramid-reinforced silicone hump hoses provide fatigue resistance at high temperatures. Custom hump hoses with a fluorocarbon liner provide increased resistance to petrochemical combustion residues. Product specifications include hose length, hump thickness, centerline length, wall thickness, hose ID, and hose OD.

Custom Silicone Wrapped Hoses

Custom silicone wrapped hoses provide enhanced pressure resistance. Before the hose is cured, nylon fabric strips are wrapped around the outer diameter. Then, during curing, pressure is applied and the material is consolidated. Unlike smooth hoses, the textile weave and distinctive ridges in a wrapped hose remain after curing. Both types of hoses can provide good abrasion resistance but wrapped hoses may support larger diameters and shorter production runs.

Other Custom Hose Connectors

Elasto Proxy can also supply you with custom hose connectors such as coolant hoses, heater and vacuum hoses, turbocharger hoses, and marine products. We offer one-stop shopping for custom shapes such as silicone knit hose, formed hose, and fluorocarbon lined hose. Plus, Elasto Proxy can also combine your shipment of custom hose couplers with the seals, gaskets, and thermal and acoustic insulation that you need for heavy equipment builds.

Coolant Hose

A custom coolant hose helps to cool your engine. It moves coolant from the radiator to the hottest part of the engine. Hot fluids are then returned to the radiator.

Vacuum Hose

A vacuum hose, line or tube routes the manifold vacuum to another part of the vehicle. Vacuum hoses can be used to power a vacuum brake booster, a windshield wiper motor, or other components or accessories.

Specifications for Custom Hose Connectors

When ordering custom hose couplers from Elasto Proxy, you’ll need to know more than just the product type or category. Here are some key specifications to consider.

- bend radius

- reinforcements

- liner materials

- pressure ratings

- industry standards

- color

Keep reading to learn more.

Bend Radius

Bend radius refers to the degree of bend in a hose connector. Although this measurement is typically 45° or 90°, Elasto Proxy can supply you with custom hose couplers with other bend radii for up to 180°. Instead of modifying your engine to fit a hose coupler, you can simply use a custom connector instead. With the rising demands of high-performance diesel engines, hose connectors with odd angles are needed both by OEMs and aftermarket suppliers.

Reinforcements and Liner Materials

Elasto Proxy can supply you with custom silicone connectors that are reinforced with fabric or metal wire.

- Fabric reinforcements typically use polyester or aramid in a four-ply construction for added strength and high-temperature resistance.

- Metal wire reinforcements help to protect silicone connectors from extreme pressures, including vacuum pressures that can cause silicone couplers to collapse.

Liner materials protect the silicone coupler from media such as hot gases or chemicals. For example, a fluorocarbon liner can enhance a silicone connector’s resistance to petrochemical residues. With air intake systems, EPDM inserts are sometimes used. With silicone connectors that use EPDM, silicone is used on the hot side of the engine and EPDM is used on the cooling side. If you need a hose connector made from EPDM, Elasto Proxy can source EPDM elbows such as 45° and 90° reducing elbows, cobra elbows, and odd angle elbows.

Pressure Ratings

Silicone rubber is known for its high-temperature resistance, but engineers need to define their application’s specific temperature range. In addition to heat tolerance, it’s important to specify both the working pressure and the burst pressure for custom silicone hose connectors Typically, the burst pressure is four times the working pressure – the recommended maximum pressure for your application.

Industry Standards

Elasto Proxy can supply you with custom silicone connectors that meet or exceed the performance and physical characteristics of

- SAE J20 R1 from SAE International

- SAE J20 R1 H.T. Class A

- SAE J1726

- TMC RP303B Grade I and Grade II

- Mil Spec A-A-52426

- Various heavy-duty OEM requirements.

For over 30 years, we’ve been a trusted supplier to the heavy equipment industry. To place an order for custom silicone connectors, contact us.

Color

Silicone connectors vary in terms of color, but the differences aren’t cosmetic.

- Red is used to designate high heat or the presence of chemicals

- Blue is used to designate cold, such as with air conditioning systems

- Black is used for standard silicone hose connectors.

In the last section of this “Ultimate Guide”, you’ll learn about MTAP.

MTAP for Custom Silicone Connectors

MTAP is an acronym that explains why industrial rubber products such as gaskets fail. It also provides a framework for thinking about how to make the right choice with custom silicone connectors. Here’s a breakdown of MTAP – and some questions you may need to ask and answer about your application.

M is for Media

The M in MTAP stands for media.

- Does the connector need to transport air (gases) or liquids (fluids)?

- Is the media corrosive?

- Is there contact with ethylene glycol or other coolants?

- Is there contact with any petroleum products?

T is for Temperature

The T in MTAP stands for temperature.

- What are the service temperatures that the connector needs to withstand?

- What are the maximum temperatures, and how long do they last?

- Is the connector next to heat source?

A is for Application

The A in MTAP is for application.

- Is it a heater hose, a coolant hose, or something else?

- Is the hose straight, or is there a bend?

- If there’s a bend, what is the angle?

- If you need an elbow, is it a standard measurement or a custom angle?

- Do you need a reducer so that the connector has different measurements?

P is for Pressure

The P in MTAP is for pressure.

- What is the working pressure?

- What is the burst pressure?

- Do you need a reinforcement material?

- If so, do you need a wire reinforcement – or something else?

- Is the application for a turbo?

- Do you need to account for vacuum pressure?

Download the Ultimate Guide for Custom Silicone Connectors. It is FREE!