Solving Sealing Challenges

Elasto Proxy solves sealing challenges through technical design, compound selection, and custom fabrication. By analyzing all of your business and technical requirements, we can:

- Improve your seal design

- Recommend the right materials

- Custom-fabricate engineered products

Let’s take a closer look.

Seal Design

Some CAD files and part drawings don’t account for the manufacturability of a seal or gasket. Schematics and blueprints can also ignore variances that occur during the extrusion of rubber or plastic products. For example, solid profiles that look perfect on paper or a computer screen won’t have precisely the same dimensions you see listed. If the gap you’re filling is tight, the profile you choose might not fit.

The Rubber Manufacturers Association (RMA) establishes allowable tolerances, but engineers who are used to working with metal parts may specify plus or minus values that are too tight for rubber products. That’s why Elasto Proxy will review your seal or gasket design carefully. We can also help you with design for manufacturability (DFM) challenges to ensure that the product you need can be made cost-effectively.

Material Selection

Some part designs call for a specialty elastomer when a commodity rubber would be sufficient. It’s important to avoid seal failure, of course, but over-engineering a seal or gasket adds unnecessary costs to a project. For example, a designer of an electronic enclosure may ask for a UL compound when it’s the entire enclosure – not just the enclosure gasket – that needs to meet the UL 94 standard.

Compared to commodity elastomers, the prices for UL compounds are higher. The minimum order quantities (MOQs) are greater, too. In the case of rubber extrusions, the compounder has to use special tooling to account for different flow rates. The number of suppliers who offer specialty is also limited. Unless you really need them, specialty compounds like this can add significant costs to your application.

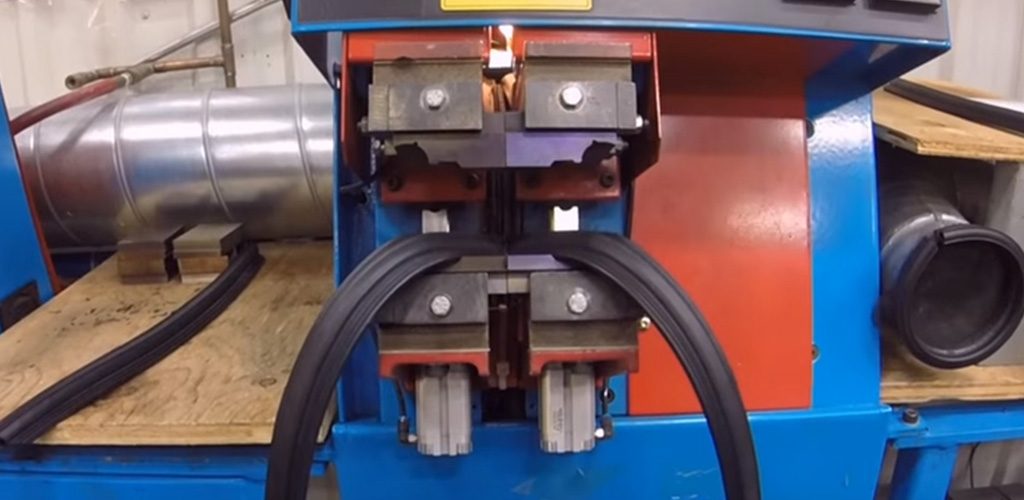

Custom Fabrication

Elasto Proxy keeps hundreds of standard rubber profiles in stock and can supply you with coils, cut lengths, or engineered products. Custom fabrication might seem more expensive than in-house manufacturing until you calculate your true costs. Mis-cuts, rework, material waste, and opportunity costs can all make in-house cutting more expensive think you may think.

At Elasto Proxy, we use CNC water jet cutting and six-axis abrasive water jet cutting machines. Both types of digital manufacturing equipment work directly from your CAD file to ensure accuracy. Elasto Proxy also provides bonding and taping services. Partners who leverage our added value manufacturing capabilities can further increase their benefits.

Download the Ultimate Customer Success Guide. It is FREE!

Discover more about Elasto Proxy’s customer success and industry standards in the guide.