Elasto Proxy supplies edge trim to manufacturers. Whether you need distribution or fabrication, we can help.

Edge trim protects exposed edges and the people who come into contact with them. It provides sealing, insulation, and a finished appearance to surfaces. Applications include metal doors on vehicles, machinery, and equipment. Edge trims are also used on the stainless steel tables in commercial kitchens and on data center server racks.

Choosing the right type of edge trim for your application is important, but you’ll also need to install these products with care. Otherwise, the rubber or plastic can buckle or separate. Elasto Proxy’s Edge Trim Guide explains how to select and install what you need. Keep reading to learn more, or contact us for a quote. We keep hundreds of rubber profiles in stock.

Edge Trim Selection

Consider these factors during product selection.

- Materials

- Dimensions

- Colors and Finishes

- Gripping

- Reinforcements

The following sections explain.

Materials

Edge trim is usually made of solid rubber or plastic materials. Choices include EPDM, neoprene, PVC, TPE, and silicone.

EPDM

EPDM resists moisture and withstands temperature extremes. It maintains its flexibility at low temperatures, provides a relatively high degree of electrical insulation, and resists sunlight.

EPDM also resists water and steam. It provides good resistance to alkalis, acids, and oxygenated solvents. Fire-rated EPDM is available for mass transit applications such as buses, subways, and trains.

Neoprene

Neoprene resists oils, greases, and other petroleum-based products. In addition to physical toughness, it offers resistance to ozone, water, weather, and a wide range of indoor and outdoor temperatures. Unlike EPDM rubber, neoprene is an elastomer that provides only limited flexibility at low temperatures.

PVC

PVC is strong, lightweight, and abrasion-resistant. It’s also cost-effective. However, polyvinyl chloride (PVC) may crack in the cold and fade in the sunlight.

TPE

TPE is less likely to crack in the cold than PVC, but it’s more expensive than other edge trim materials – including EPDM. Unliked EPDM rubber, however, TPE can be recycled and is available in a wider range of custom colors.

Silicone

Silicone is used in applications that require low toxicity, low chemical reactivity, and thermal stability over a wide temperature range. Silicone also resists water and many types of chemicals, including cleaners.

Often, silicones are used in food and beverage processing, medical, pharmaceutical, and other sanitary or hygienic applications. For medical devices and equipment, USP Class VI silicones may be required.

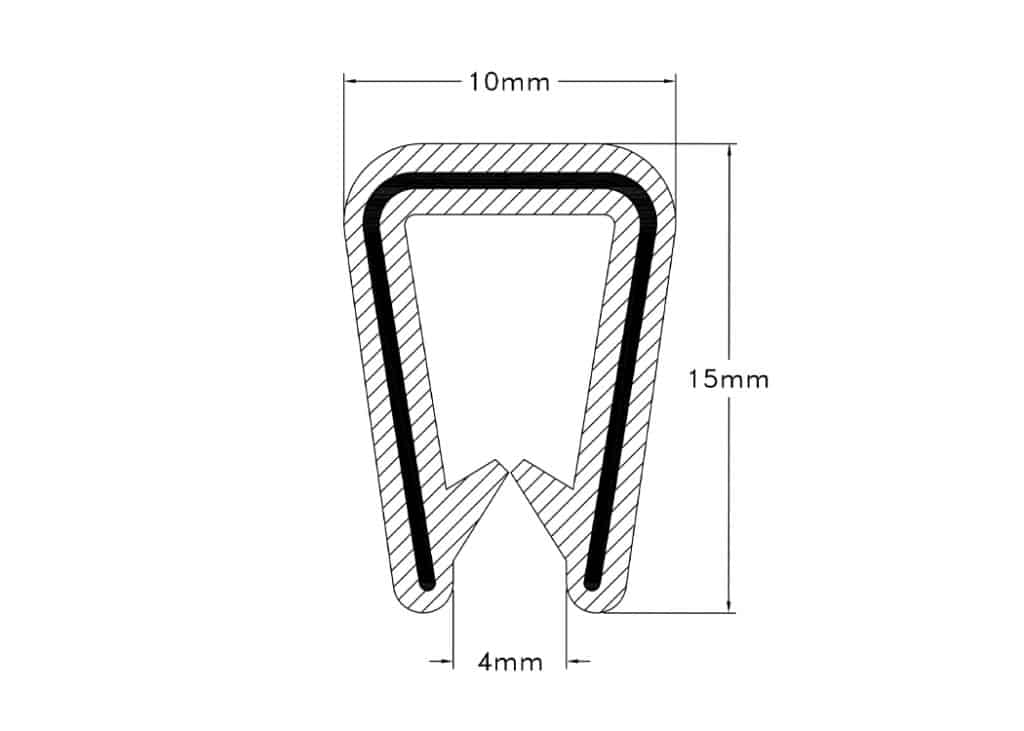

Edge Trim Dimensions

When selecting products, make sure to account for these dimensions.

- Edge thickness

- Leg length

- Bend radius

Edge Thickness

Choose a product that’s as thick as the edge you plan to cover. In other words, don’t select a trim seal that’s too thick or too thin for the flange (edge). For example, if you need to cover an edge that’s 0.125” (0.3175 cm) thick, choose a product with an edge thickness of 0.125” (0.3175 cm) – and not 0.120” (0.3048 cm) or 0.130” (0.3302 cm).

Leg Length

Select a product with legs that are long enough to cover the edge or flange. You’ll need longer leg lengths for deeper flanges and shorter leg lengths for shallower flanges.

Bend Radius

If the edge to cover is curved, measure the bend radius. To do this, determine the minimum distance from the center point to where the product must bend. Then compare this measurement to the minimum bend radius for the edge trim you’re considering. If your edge trim can’t accommodate the radius, the seal could buckle and fail.

Colors and Finishes

Elasto Proxy supplies rubber products in a choice of colors and finishes. Most edge trim is black and has a smooth surface. However, you can choose colors such as orange, white, or silver to match your product designs. You can also specify a textured or pebbled finish.

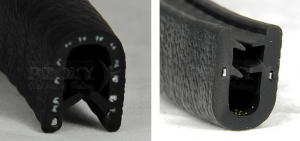

Gripping

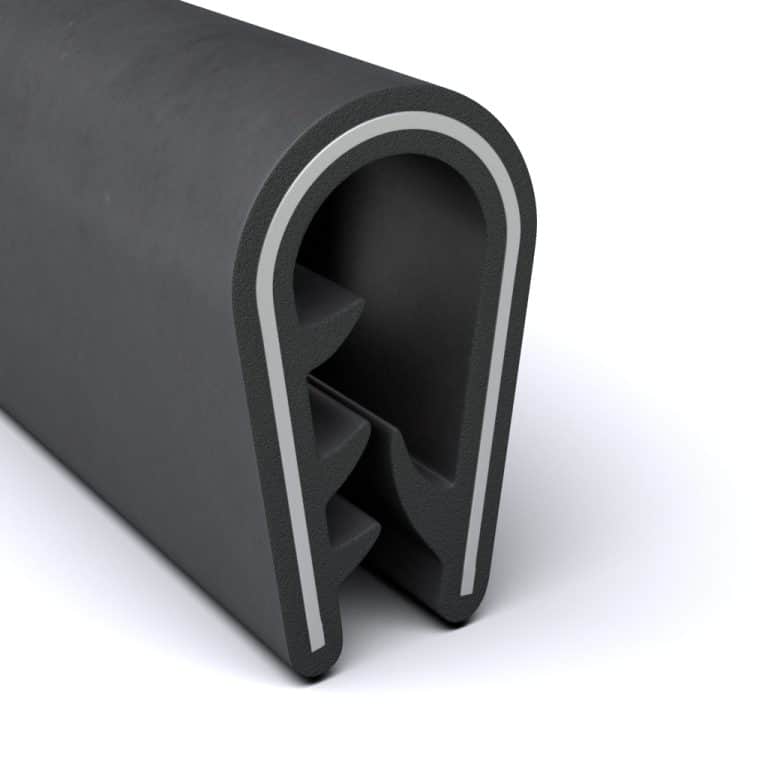

Edge trim that is properly sized fits snugly and securely over metal or plastic edges; however, for additional gripping, products can have interior tongues.

Reinforcements

Edge trims have a durometer, or hardness, that can provide either greater cushioning or greater impact resistance. Some products also contain steel wires or segmented cores for added reinforcement.

Edge Trim Installation

Installing edge trim involves pressing it into place over an edge or flange. You can use your hands or a rubber mallet, but some customers use a pneumatic hammer for higher volumes.

Make sure to install lengths of edge trim so that the ends won’t separate. Push the ends together and leave some material in the loop that’s created. Then push down on the edge trim to ensure a proper fit avoid stretching. The video below explains.

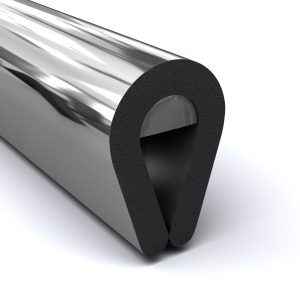

Edge Trims from Elasto Proxy

Elasto Proxy keeps hundreds of edge trims in stock. Here are some examples.

You can either order edge trims in coils that you cut yourself, or you can ask Elasto Proxy to cut edge trim to size for you. With our water jet cutting capabilities, you won’t have to wait for or pay for tooling. You’ll get precise cuts for less material waste, and you won’t have to have your employees cut gaskets when they could be doing other activities instead.