What’s the difference between solid, sponge, and foam rubber? Ultimately, it’s about whether the rubber has a cellular structure and, if so, how those cells are made and whether they permit or prevent the passage of fluids (i.e., liquids and gases). In turn, the structure of the material helps to determine its suitability not just for sealing, but for cushioning or impact resistance.

Cellular vs. Non-Cellular Rubber

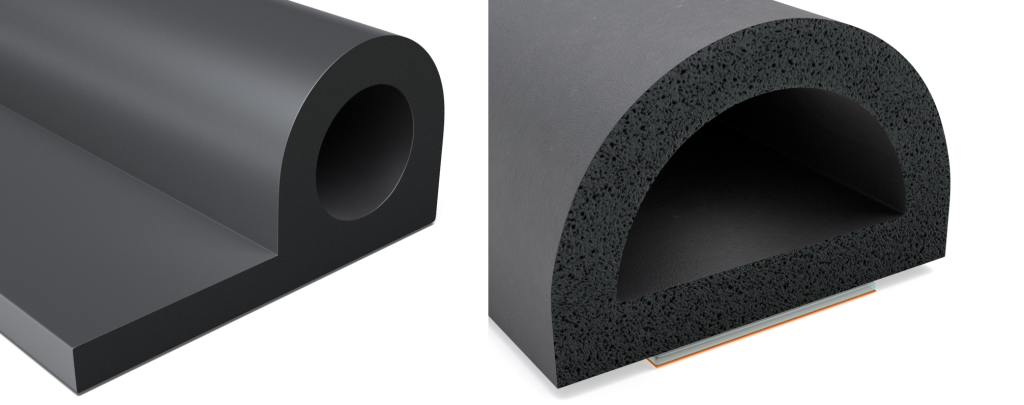

Solid rubber does not contain visible cells. By contrast, sponge rubber and foam rubber both have an observable cellular structure.

These cells can be either open or closed.

- Open cells are open, interconnected pockets that permit the passage of fluids.

- Closed cells are closed, balloon-like cells that prevent the passage of fluids.

Sponge rubber and foam rubber both have a cellular structure, but they’re made in different ways.

- Open-cell sponge rubber is made with sodium bicarbonate.

- Closed-cell sponge rubber is made with a chemical powder the decomposes during production.

- Foam rubber is made with a blowing agent instead.

These are important differences, but what are the practical implications for how solid, sponge, and foam rubber are used?

That’s what the rest of this article explains.

Solid, Sponge, and Foam Rubber for Finished Gaskets

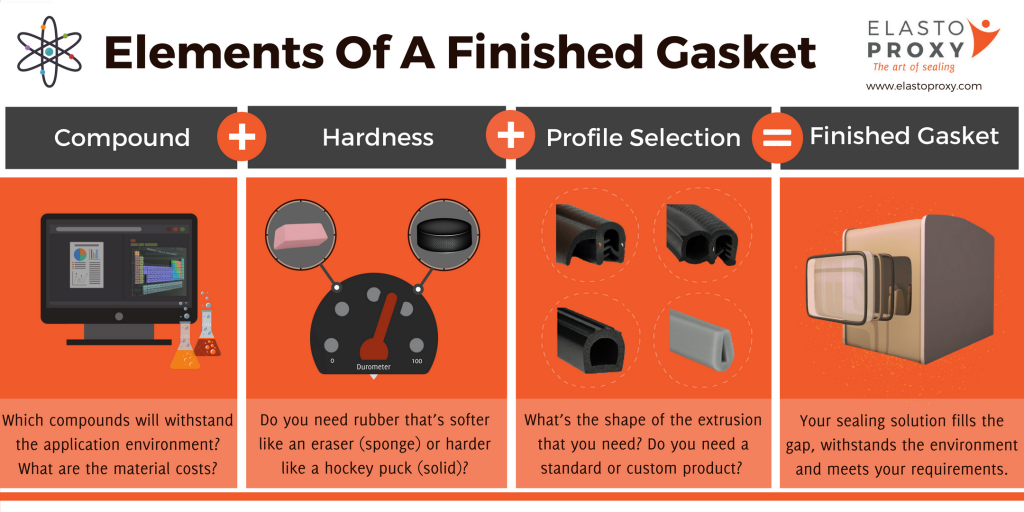

The diagram below shows the elements of a finished gasket.

Here’s what you need to know about compound, hardness, and profile selection as they relate to solid, sponge, and foam rubber.

Compound

Rubber materials are called compounds because they’re combinations of a rubber base and chemicals that provide specific properties, such as color or flame resistance. Solid, sponge, and foam rubber materials come in many of the same compounds, including EPDM, nitrile, neoprene, and silicone. Therefore, compound isn’t what makes solid, sponge, and foam rubber different.

Different compounds have different material properties. These include physical properties like tear resistance, thermal properties like service temperatures, and electrical properties like dielectric strength. In general, the solid, sponge, and foam rubber versions of a compound have similar material properties. The main exception is hardness, which affects gasket compression and sealing.

Hardness

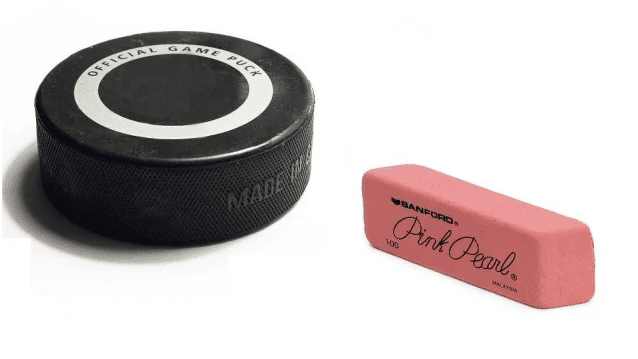

Hardness can be described as resistance to indentation. Think of hockey puck and a pencil eraser. The hockey puck is hard and resists indentation. That’s important since a player’s stick hits the puck with great force and speed. The pencil eraser is soft and compressible. That’s why a good eraser won’t tear your paper when you’re removing pencil marks.

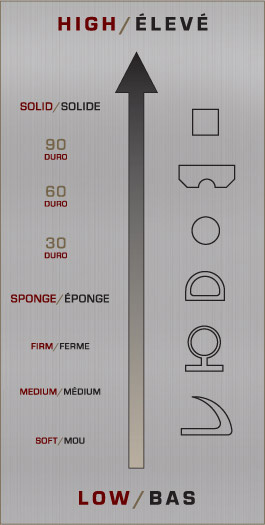

Typically, solid rubber is harder than sponge rubber. That doesn’t mean all solid rubber is harder than all sponge rubber, however. Foam rubber can be soft and flexible, or it can be hard and rigid. Thist underscores the importance of quantifying rubber’s hardness. Durometer and compressibility, two related concepts, let you put numbers to solid, sponge, and foam, rubber materials.

Durometer is a standardized way to measure and express hardness. For the rubber materials that Elasto Proxy works with, durometer is given as a number from 0 to 100 on the Shore A scale.

- Lower-durometer rubber is softer and has lower Shore A values.

- Higher-durometer rubber is harder and has higher Shore A values.

Compressibility describes how pressure reduces the size of a material. When a gasket is between a closed door and a door frame, pressure reduces the rubber’s dimensions by a certain percentage.

- Harder rubber is less compressible. In other words, it compresses by a smaller percentage.

- Softer rubber is more compressible. In other words, it compresses by a higher percentages.

Consider our example of a gasket between a closed door and a door frame. A harder rubber won’t compress as much as a softer material.

With finished gaskets, it’s essential to compress the rubber enough to produce a reliable seal but while minimizing the risk of over compression.

- Too much compression can result in compression set, meaning that the gasket won’t return to its original dimensions when the door is opened, and the pressure is removed. A crushed gasket like this won’t seal the gap between the door and door frame when the door is closed again.

- Too little compression could make the door difficult to close. Alternatively, the door could pop back open because of the gasket’s resistance to the applied pressure. In either of these scenarios, there won’t be reliable sealing since wind, water, and weather can all enter.

Compression percentages vary. Consider silicone rubber, for example. Typically, solid silicone is compressed by 15% to 20%. Sponge silicone requires a greater amount of compression, typically at least 50%. Most silicone foam is soft and flexible instead of hard and rigid, so a compression percentage of 50% is also typical.

Profiles

Profiles are rubber extrusions with a fixed cross-sectional shape, sometimes in the shape of a letter such as d, e, p, or u, and sometimes with a hollow section. Extrusion isn’t the only way rubber materials are made, however. Calendering and molding are also used, but to produce sheets instead.

Solid, sponge and foam rubber can all be supplied as either sheets or extrusions. Therefore, profile doesn’t determine whether you need a cellular or non-cellular rubber. The shape, or profile, of the rubber matters for sealing, but it’s one of many factors. That’s why at Elasto Proxy, we talk about material selection in terms of MTAP: media (M), temperature (T), application (A), and pressure (P).

Applications for Solid, Sponge, and Foam Rubber

As you’ve learned from this article, the difference between solid, sponge, and foam rubber is mainly about whether the material has a cellular structure and, if so, how those cells are made and whether they permit or prevent the passage of fluids. But how are solid, sponge, and rubber used? The structure of a material can play an important role.

- Solid rubber, depending on its durometer, can be used in products ranging from hard, impact-resistant bumpers to finished gaskets that are softer than bumpers but still hard enough to resist overcompression under high compressive forces.

- Sponge rubber is also used for sealing doors, hatches, and enclosures, typically under lower compressive forces. Because it tends to be softer than solid rubber, sponge rubber is also used for cushioning.

- Foam rubber has many of same applications as both solid rubber and sponge rubber, depending on whether it’s soft and flexible or hard and rigid.

With cellular foam rubber, remember to consider the type of cells. For example, open-cell rubber is used in foam filters that exclude dust particles but let water pass through. Closed-cell rubber is used in parts like dishwasher gaskets, which must compress under relatively low pressure while keeping water within the appliance when the dishwasher door is closed.

Now that you know about the differences between solid, sponge, and foam rubber, which type of rubber do you need? If you’re a manufacturer who needs ready-to-convert materials or fabricated products, Elasto Proxy can help. To get started, talk to our team.