Closed Cell Sponge Rubber Gaskets

Closed cell sponge rubber gaskets from Elasto Proxy don’t just meet your application requirements for sealing and insulation. They meet your business requirements for a value-added solution.

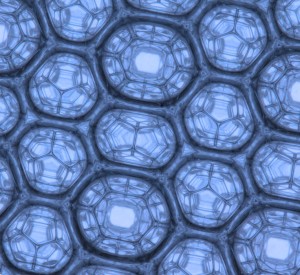

Closed cell sponge rubber gaskets prevent the flow of liquids and gases to and from the environment. They contain nitrogen-filled cells and provide reliable sealing, cushioning, gap filling, and insulation. Most sponge or expanded rubber is lightweight, flexible, and compressible. Over-compression can cause gasket failure, however, so compound selection is critical.

As an experienced gasket fabricator, Elasto Proxy helps you choose the right rubber for your application. We then custom-fabricate gaskets that save you time and money. Many types of closed cell sponge rubber are available, and different compounds provide particular properties. These sheet materials and rubber extrusions also support water jet cutting, adhesive bonding or splicing, and taping for peel-and-stick gaskets. (more…)

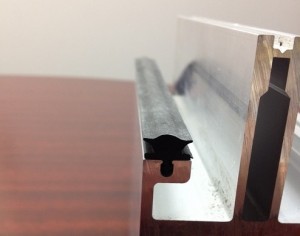

Custom skylight seals need to meet demanding environmental and load testing requirements. When a skylight company faced a sealing challenge, Elasto Proxy provided the perfect solution on a tight timetable.

Custom skylight seals need to meet demanding environmental and load testing requirements. When a skylight company faced a sealing challenge, Elasto Proxy provided the perfect solution on a tight timetable.  Infrastructure projects need sealing and insulation solutions that reduce risk and strengthen product designs. That’s why the industry chooses Elasto Proxy.

Infrastructure projects need sealing and insulation solutions that reduce risk and strengthen product designs. That’s why the industry chooses Elasto Proxy. Elasto Proxy, an experienced provider of sealing and insulation solutions, strengthens supply chains in the stainless steel and food equipment industries. Through design assistance, compound selection, and custom-fabrication, we support projects from prototyping to production. Elasto Proxy also offers value-added solutions that speed installation and optimize inventory management. Our rubber and plastic parts arrive ready-to-install, and we can ship them on-demand or according to your sales forecast.

Elasto Proxy, an experienced provider of sealing and insulation solutions, strengthens supply chains in the stainless steel and food equipment industries. Through design assistance, compound selection, and custom-fabrication, we support projects from prototyping to production. Elasto Proxy also offers value-added solutions that speed installation and optimize inventory management. Our rubber and plastic parts arrive ready-to-install, and we can ship them on-demand or according to your sales forecast.  For over 25 years, Elasto Proxy has strengthened manufacturing supply chains by providing low-to-medium volumes of specialty seals and insulation. Through design assistance, compound selection, and custom fabrication, we support the medical and healthcare industries from prototyping to production. Elasto Proxy also offer solutions that speed installation and optimize inventory management, saving you time and money.

For over 25 years, Elasto Proxy has strengthened manufacturing supply chains by providing low-to-medium volumes of specialty seals and insulation. Through design assistance, compound selection, and custom fabrication, we support the medical and healthcare industries from prototyping to production. Elasto Proxy also offer solutions that speed installation and optimize inventory management, saving you time and money.