Learn how Elasto Proxy helped a manufacturer of food service equipment solve a sealing and insulation challenge with food prep tables.

Food prep tables and other food service equipment generally features stainless steel construction. Strong, durable, and corrosion-resistant, stainless steel is easy-to-clean and ideal as a food contact surface. Surface finishing treatments such electropolishing inhibit bacterial attachment and biofilm formation, which helps to prevent foodborne illness. Food prep tables with refrigeration systems also help keep ingredients at the proper temperatures for freshness and taste.

By following proper procedures, stainless steel surfaces can be kept shiny and clean. That includes metal surfaces where items like sandwiches and salads are assembled, as well as the pans and shelves that hold the ingredients. Yet food prep tables are built with non-metallic materials, too. Silicone seals fill slots and surround metal edges in food storage areas. They cover sharp surfaces, seal gaps, and support refrigeration. All silicone rubber is not the same, however, so it’s important to choose the right compound.

FDA Approved Silicone for Food Contact Applications

When a manufacturer of food service equipment needed rubber parts for food prep tables, Elasto Proxy provided a complete sealing and insulation solution. The silicone seals we supply are made of FDA approved silicone rubber, which means that they meet CFR 21.177.2600 regulations from the Food and Drug Administration (FDA). Although the FDA’s jurisdiction is limited to the United States, FDA standards are followed worldwide.

Many suppliers offer food-grade silicones, but compounds that are FDA compliant aren’t necessarily FDA approved. Under FDA guidelines, silicone is a food contact substance (FCS) that’s subject to extraction test limits for various chemicals that can leach or off-gas. Importantly, all of the additives in silicone must be approved in order for the FCS to be fully-approved. The silicone that Elasto Proxy sources for food prep tables is fully FDA-approved, an important consideration for many food service equipment manufacturers.

Silicone Seals for Safe, Sanitary Applications

FDA approved silicones are also a good choice because of application conditions. A synthetic rubber, silicone repels water from frequent wash-downs and forms watertight seals. Silicone also offers excellent thermal stability, which means that this compound provides constant material properties over a wide temperature range (–100 to 250° C). The ingredients kept in food prep tables are stored at temperatures above freezing (0°), but the rubber seals must be able to withstand refrigerated airflows.

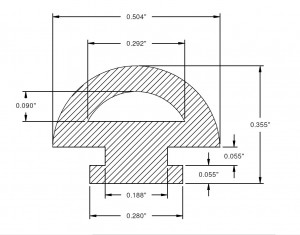

The silicone seals that Elasto Proxy supplies also help keep refrigeration systems working effectively. By filling the gaps from which cooler air could escape, silicone seals promote energy efficiency, too. Because silicone supports the use of colorants, Elasto Proxy can supply gray-colored seals to match food prep table designs. For the equipment manufacturer that needed a complete sealing and insulation solution, Elasto Proxy provides profiles in 400-ft. rolls that are easy-to-cut and then slide into slots on the table

How Can We Help You?

Do you need FDA approved silicone seals for food service equipment such as food prep tables? Do you need high-temperature silicone seals for restaurant ovens, or silicone mats for the production of baked goods? For over 25 years, Elasto Proxy has supplied sealing and insulation solutions to the stainless steel and food equipment industries. We’ve created rubber seals for beverage processors, too. How can we help you? For more information about our capabilities, or to tell us what you need, please contact us.