How much do you know about Elasto Proxy’s capabilities? Maybe you place an occasional order for coils. Maybe you receive releases of gaskets against a blanket purchase order instead. Regardless, Elasto Proxy is both a distributor and a fabricator. We also do more – a lot more.

If you haven’t talked to Elasto Proxy in a while, now is a great time to learn what else we can do for you. Why take a chance on an untested supplier when what you may need is available from a trusted partner?

Let’s examine five things you need to know about Elasto Proxy’s capabilities. This isn’t all we can do for you, but what you’ll learn is what some customers tell us they didn’t realize.

- We’re not just a distributor

- We use water jet cutting

- We make finished gaskets

- We supply cut lengths

- We offer parts marking and kitting

Keep reading to learn more, watch the video below, and contact us for a quote.

Rubber Distribution and Custom Fabrication

Elasto Proxy isn’t just a distributor. We can supply the rubber materials that you need, but we can also custom-fabricate your seals, gaskets, and insulation. Cutting your own gaskets may seem cost-effective, but are you accounting for material waste? What is the cost of rework, and how much time are higher-paid employees spending on labor-intensive tasks that don’t require their skill levels? If you didn’t know that Elasto Proxy is a custom fabricator, then learning more about us could save you time and money.

Water Jet Cutting

Elasto Proxy uses water jet cutting to create prototype parts and low-to-medium production volumes. With water jet cutting, there no tooling to pay for or wait for. Just sent us your CAD file and we’ll transmit your digital drawing to our state-of-the-art equipment. Water jet cutting supports design changes and quick-turn prototyping, but it’s also great for seals, gaskets, and insulation that require fast cuts with tight tolerances. Water jet cutting is great for corners and notching, too. Talk to us to learn more.

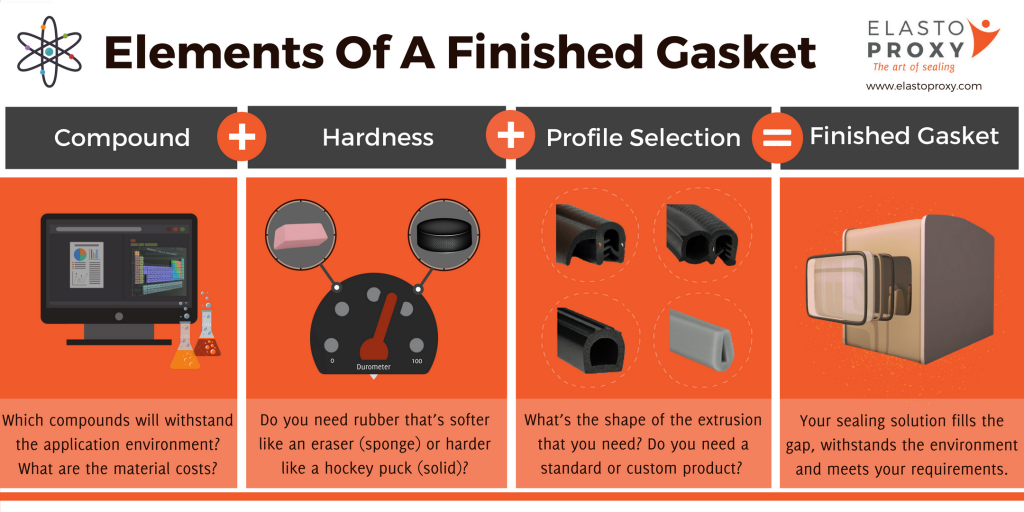

Finished Gaskets

Elasto Proxy’s custom fabrication capabilities include your choice of joining techniques for finished gaskets. Hot splicing and vulcanizing are methods that use heat, pressure, and a film splice or uncured rubber to join the ends of profiles. Cold bonding joins lengths of cut materials without the use of heat. Molding is more expensive, but it’s the only way to create radiused corners. To learn more about each of these joining techniques and its advantages, ask Elasto Proxy.

Cut Lengths

Elasto Proxy doesn’t just supply coils of rubber for you to cut. We also supply cut lengths that meet tolerances from the Rubber Manufacturers Association (RMA). If you try to cut coils yourself, you may stretch the rubber beyond these limits. Molded and extruded rubber can shrink or rip, too. With bulb trim seals, for example, cutting and installation can challenge even experienced assemblers. By contrast, cut lengths from Elasto Proxy can fit part features like door hinges.

Parts Marking and Kitting

Elasto Proxy can also group your parts into kits and mark individual components with identifying features. Thanks to inkjet printing and UV drying, our parts marking system produces letters and numbers that are crisp, clean, and easy-to-read. By packaging everything your installers need into a single box, you’ll save time and money on your assembly line. Instead of looking for 10 or 20 different SKUs in a warehouse, an installer can just open the box and get to work.

For value-added manufacturing, contact Elasto Proxy.