Custom skylight seals need to meet demanding environmental and load testing requirements. When a skylight company faced a sealing challenge, Elasto Proxy provided the perfect solution on a tight timetable.

Custom skylight seals need to meet demanding environmental and load testing requirements. When a skylight company faced a sealing challenge, Elasto Proxy provided the perfect solution on a tight timetable.

Skylights are specialized windows that builders install in a roof or ceiling. They admit natural light, provide a visual connection to the outdoor environment, and support passive solar heating. Skylights can help reduce energy costs, but their benefits go beyond sustainability. For example, the giant domed skylights found atop some commercial buildings are designed to enhance the occupants’ overall experience. By combining art with infrastructure, these complex structures truly illustrate the art of sealing. If a skylight fails, however, property damage and personal injury may result.

Custom Skylight Seals: The Challenge

When a Canadian company that designs, manufactures, and installs custom skylights faced a sealing challenge, Elasto Proxy’s branch in Newmarket, Ontario received an urgent email. The skylight company, an Elasto Proxy customer, needed 50,000 ft. of a custom rubber extrusion for a major project in the Middle East. Branch Manager John Rye had worked with the company on a previous project that required a large, sliding skylight system for restaurants. Within 24 hours, Elasto Proxy visited the skylight company’s facility to determine the requirements and recommend a solution.

When a Canadian company that designs, manufactures, and installs custom skylights faced a sealing challenge, Elasto Proxy’s branch in Newmarket, Ontario received an urgent email. The skylight company, an Elasto Proxy customer, needed 50,000 ft. of a custom rubber extrusion for a major project in the Middle East. Branch Manager John Rye had worked with the company on a previous project that required a large, sliding skylight system for restaurants. Within 24 hours, Elasto Proxy visited the skylight company’s facility to determine the requirements and recommend a solution.

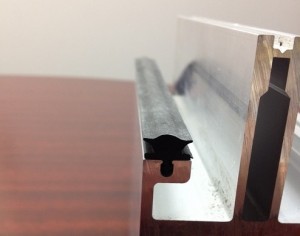

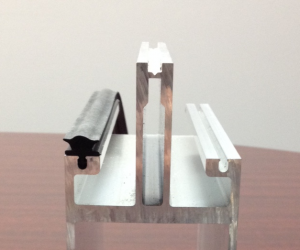

As John Rye learned, the window seal needed to fit a metal channel in a larger aluminum structure. The window rubber would lock in place, but metal wasn’t the only material in the giant domed skylight. The glass that would rest atop the seal was thick and heavy with variations of up to 2 millimeters. As the skylight company explained, the glass could not make contact with the metal. In addition to the heavy load from the window glass, the rubber seal must withstand extreme heat, coastal humidity, and strong winds. The different expansion rates of metal, glass, and rubber were also important to consider. The skylight builder would cut the rubber seals to size, but needed a specialized elastomer.

To further complicate this sealing challenge, time was short. The skylight company’s request arrived in April, but the window rubber needed to be on a boat bound for the Middle East by the end of May. Design assistance and engineering support were also essential. Without adequate load testing, the window rubber’s ability to withstand the application environment would remain unknown. That’s why the skylight company chose Elasto Proxy, a proven partner with the application knowledge and technical expertise to eliminate supply chain uncertainty. The dual durometer EPDM rubber that Elasto Proxy supplied solved the sealing challenge on a tight timetable – and with the added benefit of ease-of-installation.

Custom Skylight Seals: The Solution

Elasto Proxy’s supply chain strength supported the on-time delivery of a value-added solution. Typically, the tooling for a custom rubber extrusion takes 4 to 6 weeks and one or more sample runs. By leveraging the power of Elasto Proxy’s supplier network, however, tooling was completed in just two weeks. Rapid prototyping also supported this time-sensitive effort. Ultimately, however, speed alone was only part of the solution. Without the right rubber, the window seal could fail in the field even if all 50,000 ft. arrived on-time.

Elasto Proxy’s supply chain strength supported the on-time delivery of a value-added solution. Typically, the tooling for a custom rubber extrusion takes 4 to 6 weeks and one or more sample runs. By leveraging the power of Elasto Proxy’s supplier network, however, tooling was completed in just two weeks. Rapid prototyping also supported this time-sensitive effort. Ultimately, however, speed alone was only part of the solution. Without the right rubber, the window seal could fail in the field even if all 50,000 ft. arrived on-time.

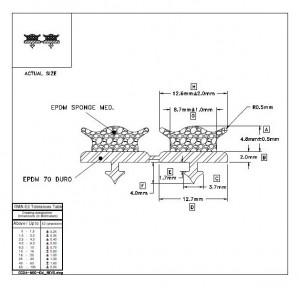

By load testing the dual-durometer extrusion at its global headquarters in Boisbriand, Canada, Elasto Proxy’s technical team verified the seal design. As the schematic that accompanies this case study shows, the top portion of the window seal was medium-durometer EPDM sponge rubber that would resist compression set. The bottom portion, 70-durometer EPDM, was about as hard as the rubber used on car tires or the soles of running shoes. Because the rubber was designed and extruded two-up due to volume, the seals had a tear line that supported separation during installation.

Do You Need Custom Skylight Seals?

Are you facing a sealing challenge with custom skylights, retractable roofs, or other building and construction project? For over 25 years, Elasto Proxy has served the infrastructure industry. To learn more about how we can help you, please contact us.