Seal Rounded Corners by Starting with These Three Measurements

Do you need to seal rounded corners against wind, water, dust, or dirt? Bulb trim seals are industrial rubber products that provide sealing and insulation for machine doors, vehicle hatches, and equipment enclosures. They’re designed to seal rounded corners and have separate bulb and retainer sections. Each of these sections can use a different material and have a different durometer or hardness.

Do you need to seal rounded corners against wind, water, dust, or dirt? Bulb trim seals are industrial rubber products that provide sealing and insulation for machine doors, vehicle hatches, and equipment enclosures. They’re designed to seal rounded corners and have separate bulb and retainer sections. Each of these sections can use a different material and have a different durometer or hardness.

With bulb trim, the bulb section compresses to form a seal when the door, hatch, or enclosure is closed. The trim or retainer section attaches to a flange or substrate. To choose bulb trim for your application, you need to specify the bulb size, bend radius, and flange thickness. By choosing the right bulb size, you can avoid over-compression. The right bend radius and flange thickness help to avoid kinking and leakage. (more…)

Do you need thermal, acoustic, or thermal-acoustic insulation for forestry, mining, construction, or other types of mobile equipment? Maybe you need cabin flooring or floormats instead. The Elasto Bag, a sack full of samples from Elasto Proxy, contains sealing and insulation that you can see for yourself and hold in your hands. It’s easy to request an Elasto Bag, but what’s inside when you get it?

Do you need thermal, acoustic, or thermal-acoustic insulation for forestry, mining, construction, or other types of mobile equipment? Maybe you need cabin flooring or floormats instead. The Elasto Bag, a sack full of samples from Elasto Proxy, contains sealing and insulation that you can see for yourself and hold in your hands. It’s easy to request an Elasto Bag, but what’s inside when you get it? Cold bonding for finished gaskets joins cut lengths of rubber without the use of heat. This bonding technique isn’t performed under low-temperature conditions but is manual process that requires a brush and glue. By contrast, injection molding is a semi-automated process that uses a C-press machine with a heated barrel, metal plates, and tons of pressure. To join cut lengths, uncured rubber is used.

Cold bonding for finished gaskets joins cut lengths of rubber without the use of heat. This bonding technique isn’t performed under low-temperature conditions but is manual process that requires a brush and glue. By contrast, injection molding is a semi-automated process that uses a C-press machine with a heated barrel, metal plates, and tons of pressure. To join cut lengths, uncured rubber is used. Hot splicing uses heat, pressure, and a film splice to join the ends of rubber profiles into bonded gaskets. This joining technique uses either a conventional heating source or infrared (IR) light and polyethylene (PE) film. Hot splicing creates strong bonds at the molecular level and generally provides better results than vulcanization, a bonding technique that uses uncured rubber instead of a film splice.

Hot splicing uses heat, pressure, and a film splice to join the ends of rubber profiles into bonded gaskets. This joining technique uses either a conventional heating source or infrared (IR) light and polyethylene (PE) film. Hot splicing creates strong bonds at the molecular level and generally provides better results than vulcanization, a bonding technique that uses uncured rubber instead of a film splice. Rubber profiles come in lengths that are cut-to-size and fabricated into finished gaskets. Examples include picture frame or bezel gaskets, O-rings, and gaskets with rounded corners.

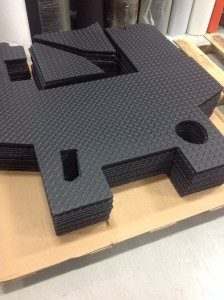

Rubber profiles come in lengths that are cut-to-size and fabricated into finished gaskets. Examples include picture frame or bezel gaskets, O-rings, and gaskets with rounded corners. Rubber floor mats for mobile equipment protect cabin floors from damage and operators from slip-and-fall hazards. Rubber flooring that’s laminated to acoustic insulation also absorbs noise from the engine compartment, which is often directly below the cab where the operator sits. Rubber matting can even be used as a kick-plate to protect cabin walls from contact with an operator’s boots.

Rubber floor mats for mobile equipment protect cabin floors from damage and operators from slip-and-fall hazards. Rubber flooring that’s laminated to acoustic insulation also absorbs noise from the engine compartment, which is often directly below the cab where the operator sits. Rubber matting can even be used as a kick-plate to protect cabin walls from contact with an operator’s boots. Custom cab insulation absorbs sound and provides a finished appearance to mobile equipment interiors. This acoustic insulation can be cut by hand and applied with spray adhesives, but that process is expensive, wasteful, and even hazardous to human health. Plus, manual cutting can result in cabin insulation that’s unappealing. Buyers who see mis-cuts may question the quality of your overall equipment design.

Custom cab insulation absorbs sound and provides a finished appearance to mobile equipment interiors. This acoustic insulation can be cut by hand and applied with spray adhesives, but that process is expensive, wasteful, and even hazardous to human health. Plus, manual cutting can result in cabin insulation that’s unappealing. Buyers who see mis-cuts may question the quality of your overall equipment design. Window channels are rubber gaskets that hold window glass in place and help to secure window frames. They also eliminate rattling and provide protection against wind, water, dust, and debris. Applications for window channels include mobile equipment, defense, medical and health, stainless steel and food equipment, infrastructure, and aerospace.

Window channels are rubber gaskets that hold window glass in place and help to secure window frames. They also eliminate rattling and provide protection against wind, water, dust, and debris. Applications for window channels include mobile equipment, defense, medical and health, stainless steel and food equipment, infrastructure, and aerospace. Industry 4.0 is a catchphrase and buzzword that you can no longer afford to ignore. This fourth phase of the Industrial Revolution isn’t just about the increased digitization of manufacturing. It’s not just about advances in automation either. Industry 4.0 could change how your company competes and whether or not you’ll continue to win. Industry 4.0 isn’t just about technology. It’s about profitability.

Industry 4.0 is a catchphrase and buzzword that you can no longer afford to ignore. This fourth phase of the Industrial Revolution isn’t just about the increased digitization of manufacturing. It’s not just about advances in automation either. Industry 4.0 could change how your company competes and whether or not you’ll continue to win. Industry 4.0 isn’t just about technology. It’s about profitability.