Vibration dampers dissipate the energy that causes resonant vibrations in built structures. Vibration, a back-and-forth movement or oscillation, produces structure-borne noise in machine enclosures, engine bays, generator sets, heavy trucks, military vehicles, and many other applications. Vibrations can also damage parts, loosen fasteners, weaken soldered connections, and suggest poor quality.

Vibration dampers dissipate the energy that causes resonant vibrations in built structures. Vibration, a back-and-forth movement or oscillation, produces structure-borne noise in machine enclosures, engine bays, generator sets, heavy trucks, military vehicles, and many other applications. Vibrations can also damage parts, loosen fasteners, weaken soldered connections, and suggest poor quality.

For engineers, it’s important to understand that objects have a frequency at which vibration occurs. With resonant vibrations, multiple objects vibrate at the same frequency. For example, the low-frequency rumble of a big diesel engine can cause a vehicle’s windows to rattle. These vibrations don’t just produce unwanted sounds. They can also damage the window glass.

In this article, the last in a series about custom acoustic insulation, Elasto Proxy explains what engineers need to know about the different types of vibration dampers. You’ll also learn how this type of custom acoustic insulation is cut from sheets and bonded to other types of materials.

Types of Vibration Dampers

Vibration dampers are made of extruded vinyl, asphalt-impregnated paperboard, metal foil, or fiberglass.

Extruded vinyl dampers are flexible, lightweight, and available in grades that meet specific standards. For example, vinyl that meets UL 94 V0 flammability requirements is used in hospital equipment, kitchen appliances, and computer housings. Vinyl that meets ASTM E662 for the optical density of smoke and ASTM 162 for surface flammability is used in buses, trains, and subways.

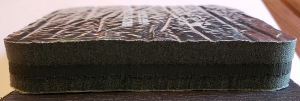

Asphalt-impregnated paperboard dampers are odorless, wear-resistant, waterproof, lightweight, and cost-effective. Like extruded vinyl, they’re supplied in sheets that can be cut to size and then laminated to other materials. For example, asphalt-impregnated paperboard can be laminated to sound barriers. Asphalt-impregnated paperboard can also be bonded to flat or curved panels in built structures.

Metal foil dampers can be applied directly to structural components or bonded to other types of insulating materials. For example, aluminum foil can provide the facing for a sandwich-like structure that includes a sound absorber and a heat blocker. To support vibration damping, metal foils can be embossed so that raised features in the foil disrupt sound waves as they travel across the surface.

Fiberglass dampers are made of a reinforced plastic that’s composed of glass fibers embedded in a resin matrix. These thin, composite materials include laminates with a viscoelastic compound that’s sandwiched in the center. For optimum damping performance, both outer layers of the fiberglass may have the same thickness. Applications include acoustic hoods and housings.

How Vibration Dampers are Made

Vibration dampers are cut from sheet materials and can be laminated to other types of insulation. They can also feature a release liner with a pressure-sensitive adhesive (PSA) for peel-and-stick installation. For engineers, it’s important to understand how choosing the right fabrication method affects cost, consistency, and quality.

Cutting can be done in-house or by a custom fabricator. Manual cutting with a knife, saw, or other hand tools may seem cost-effective, but poor-quality cuts can result in rework and material waste. By contrast, water jet cutting creates fine, fast, consistent cuts that maximize material yields. Plus, unlike die cutting, there’s no paying for or waiting for tooling with water jet technology.

Laminating combines vibration dampers with other types of materials in a sandwich-like structure. To avoid delamination, this bonding process requires the right adhesives and the efforts of skilled production personnel. Some vibration damping materials, such a fiberglass with a viscoelastic core, are laminated when they’re manufactured. Other vibration dampers are laminated during custom fabrication.

Find Vibration Dampers for Structure-Borne Noise

The article you’ve been reading is the last in a series about how to stop noise with custom acoustic insulation. For more information, please contact Elasto Proxy. You can also ask for the Elasto Bag to see some sample insulation for yourself.