Rubber profiles come in lengths that are cut-to-size and fabricated into finished gaskets. Examples include picture frame or bezel gaskets, O-rings, and gaskets with rounded corners.

Rubber profiles come in lengths that are cut-to-size and fabricated into finished gaskets. Examples include picture frame or bezel gaskets, O-rings, and gaskets with rounded corners.

There are four ways to bond or join the ends of rubber profiles.

- Hot Splicing

- Vulcanization

- Cold Bonding

- Molding

Each bonding or joining method has its advantages, but what’s the best choice for your application? Let’s examine each method in detail so that you can make the right decision.

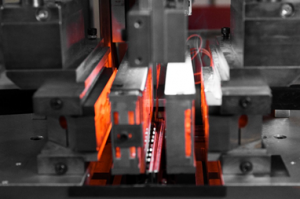

Hot Splicing

Hot splicing uses heat, pressure, and a thin PE film splice to join the ends of rubber profiles. This bonding technique is called “hot” because it uses either a conventional heating source or infrared light (IR). Traditional splicing takes longer than IR splicing, but both methods create strong bonds. Most film splices are 90°, but hot splicing also supports 45° miter cuts and endless gaskets.

Hot splicing uses heat, pressure, and a thin PE film splice to join the ends of rubber profiles. This bonding technique is called “hot” because it uses either a conventional heating source or infrared light (IR). Traditional splicing takes longer than IR splicing, but both methods create strong bonds. Most film splices are 90°, but hot splicing also supports 45° miter cuts and endless gaskets.

Hot splicing requires clean, straight cuts but supports higher production volumes. The type of profile usually determines whether a conventional heat source or IR light is used. IR splicing is a good choice for sponge rubber profiles because IR won’t burn the elastomer. IR splicing can also accommodate larger profiles and requires less post-production trimming. With silicones, however, traditional splicing is used.

Vulcanization

Vulcanization uses heat, pressure, and uncured rubber that’s made of the same elastomer as the profile itself. Compared to hot splicing, this bonding technique is more forgiving since the cuts don’t have to be smooth and precise. With vulcanization, uncured rubber is applied to the profile’s ends. After the ends are pressed together, the joint is placed into a hot mold.

Applications for vulcanization include O-rings, tubing, and other industrial rubber products with a space for the free-flowing passage of air to the gasket. Vulcanization can’t match hot splicing in terms of results, but vulcanized seals and gaskets are good for low volumes.

Cold Bonding

Cold bonding is a manual process that’s performed with a brush and an adhesive or glue. This technique is called “cold” because no heat is applied to the ends of the gasket. Bonding systems include low, medium, and high viscosity adhesives in cyanoacrylate, silicone, and epoxy formulas. Glues may be designed for specific types of rubber or crystalize when they contact water.

Cold bonding is a manual process that’s performed with a brush and an adhesive or glue. This technique is called “cold” because no heat is applied to the ends of the gasket. Bonding systems include low, medium, and high viscosity adhesives in cyanoacrylate, silicone, and epoxy formulas. Glues may be designed for specific types of rubber or crystalize when they contact water.

Cold bonding or gluing doesn’t require metal tools called dies, but cold bonded gaskets won’t last as long as hot spliced ones. Plus, cold bonding is more expensive than hot splicing. Compared to molding, however, cold bonding costs less because there’s no metal tooling. Gasket fabricators can add labor to projects, but most cold bonded gaskets are produced in low-volume quantities.

Molding

Molding is the only bonding technique that can create rounded corners for rubber gaskets. This joining method is also recommended for gaskets with corners that will be stretched or pulled. Compared to hot splicing, molding produces stronger joints and offers increased resistance to leaking. Molding is also recommended for bulbs with difficult shapes.

Molding is the only bonding technique that can create rounded corners for rubber gaskets. This joining method is also recommended for gaskets with corners that will be stretched or pulled. Compared to hot splicing, molding produces stronger joints and offers increased resistance to leaking. Molding is also recommended for bulbs with difficult shapes.

Molded gaskets require tooling and C-press injection molding equipment. The cost of a metal mold can be significant, but tooling that’s used across higher volumes of gaskets has a lower unit cost. Molding is generally used with larger production runs; however, molding is not recommended for silicone or sponge profiles.

Get The Sample Kit

Elasto Proxy is a gasket fabricator that provides a choice of joining methods. Our capabilities include hot splicing, vulcanization, cold bonding, and molding. We also keep hundreds of profiles in stock and use water jet cut cutting or abrasive water jet cutting. To see samples of our rubber products – including spliced corners – ask for our Sample Kit.