Cab door seals prevent water, dust, outside air, and noise from entering the cabin where a heavy equipment operator sits. Applications include agricultural, construction, forestry, and mining equipment as well as emergency vehicles and ground service equipment. Often, these door gaskets are fabricated from EPDM bulb trim that snaps into place or comes with PSA tape for quick, permanent fastening.

Elasto Proxy makes cab door seals for heavy equipment manufacturers, and in lower quantities than you can get from an extruder. We keep hundreds of different rubber profiles in stock, cut and bond them according to your drawings, and can provide you with regular shipments or just-in-time inventory. With our warehousing capabilities, we can also help you to avoid stockouts and get on-time deliveries.

Today, many of the heavy equipment manufacturers who work with us share their production forecasts and issue Elasto Proxy a blanket purchase order. We then buy all the materials they need and store them in our warehouses. These manufacturers conserve cash and floor space at their facilities, and they can buy hundreds of cab door seals at a time instead of having to order tens of thousands of parts.

Contact Elasto Proxy for a quote, or keep reading to learn more.

Door Seal Design and Material Selection

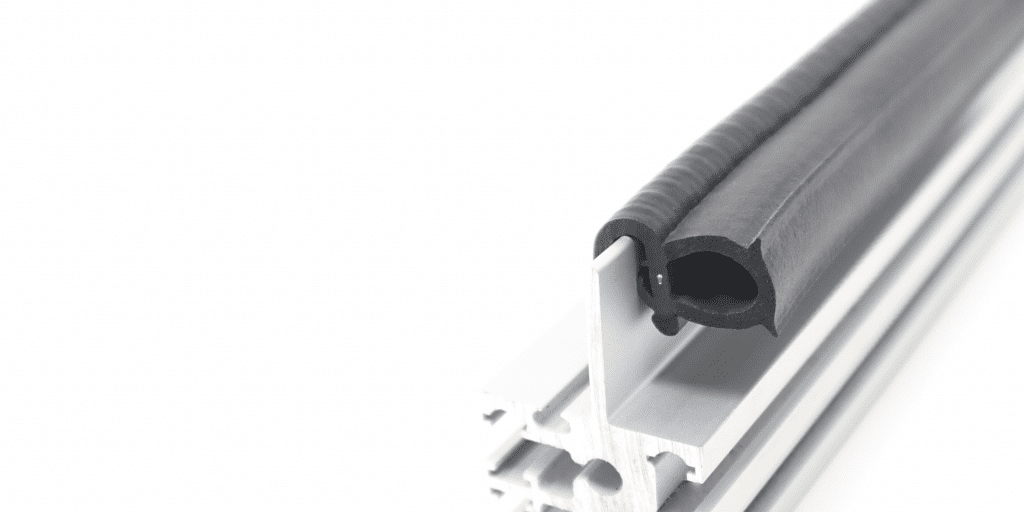

Cab door seals are made of industrial rubber products called bulb trim. These dual-durometer extrusions have a soft, compressible bulb that fits between the door and the door jamb. When the cab door is closed, the bulb compresses to form a seal. When the cab door is opened, the bulb returns to its original dimensions. The trim, or retainer, section is made of a harder rubber that attaches to the door.

Generally, the bulb section of a trim seal is round; however, you can also choose a bulb that is shaped like the letter D or a teardrop. Depending on your design, the bulb can be on top of the trim or to its side. Today, most bulb trim for cab door seals is made of weather-resistant EPDM rubber. Elasto Proxy can also supply you with door gaskets made of TPEs, which cost more than EPDM but are recyclable.

Prior to fabrication, bulb trim arrives in standard lengths and is stored as coils. Because Elasto Proxy is both a fabricator and a distributor, we can provide you with coils if you need them. However, the value that we offer through custom fabrication can save you time and money. Cutting and bonding in-house might seem less expensive, but consider the advantages of working with us – and your true costs.

Cutting, Bonding, and Installing Cab Door Seals

Elasto Proxy uses water jet cutting to convert standard lengths of bulb trim into cut lengths for gaskets. There’s no tooling to pay for or wait for, and we can make angled cuts with speed and precision. Compare that to cutting lengths in-house by hand. You probably won’t know how much material is wasted by miscuts, and the cut quality you’ll get from hand tools can’t match digital manufacturing.

Working with Elasto Proxy also means you get a choice of gasket bonding methods. For low volumes, cold bonding is often the way to go. For cab door seals with super-strong bonds, gaskets with vulcanized corners might be your best bet instead. For larger, thicker gaskets, PE film splicing gets great results and has fast cycle times, especially with EPDM door seals.

Some cab door seals are designed to snap into place, but Elasto Proxy can also provide you with finished gaskets that come with PSA tape. When these door seals arrive, your installers simply remove the tape’s backing and stick the gasket in place for permanent fastening. For cab door seals that provide greater value, ask Elasto Proxy.