Extruded rubber tolerances for seals and gaskets are different. Find out why and use the tolerance tables in this article.

Tolerances are dimensional differences you’ll accept between two or more of the same part. They are decimal-based, and they’re given in both inches (in) and millimeters (mm). If you’re designing a seal or gasket that’s made of extruded rubber, it’s important to realize that the tolerances you put on your drawing can’t be as tight and fine as the ones you’d use with metal components. But why is that the case?

There are two main reasons for this. First, rubber is more sensitive than metal to changes in temperature and humidity. Second, the rubber extrusion process uses different tooling and equipment than metalworking. Specifically, extruded rubber is forced through a cross-sectional die while under pressure. Dies are precision-made tools, but rubber increases in size when exiting the die orifice.

Knowing that extruded rubber tolerances are different can save you from having to revise your gasket’s dimensions at the last minute. It can also save you from having to modify a larger product design, such as an enclosure, so that an extruded rubber gasket will fit. It’s better to design a seal sooner than later, but some designers wait until the end when it’s harder to make changes. It’s best to avoid that.

This article from Elasto Proxy gives you the part tolerances you’ll need when you design seals or gaskets from rubber extrusions in our catalog. This downloadable PDF refers to drawing designations from the Association of Rubber Product Manufacturers (APRM), an organization that used to be known as the Rubber Manufacturers Association (RMA). That’s why you’ll see RMA information for individual products.

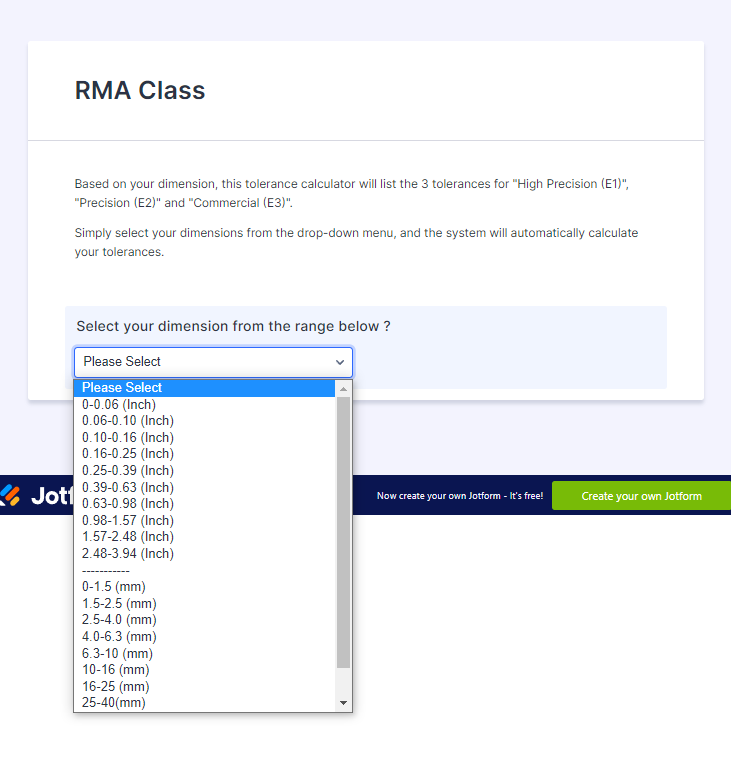

Keep reading to learn more, download our catalog to see some of what we have available (this is just some of what we can provide!) or contact us to request a quote. We can also offer you gasket design assistance if you need it. We even have a Tolerance Calculator in our Resource Center.

Extruded Rubber Tolerance Tables

The ARPM organizes extruded rubber part tolerances into tables so that the information is easy to find and use. There are plenty of numbered tolerances tables in the ARPM Handbook (or the RMA Handbook, as it used to be called), but Tables 13, 38, and 39 are the ones you’ll need when you buy rubber extrusions as coils. You’ll find these tables listed below.

Before you begin, please note that there are ARPM classes within each table. As a rule, rubber extrusions that meet the requirements of higher precision classes are more expensive. That’s another reason why it’s worth taking the time for gasket design sooner than later. Otherwise, you might have to use a higher-precision extrusion so that you don’t have to change a larger product design.

ARPM Table 13

Tolerances for outside (O.D.) diameters, inside (I.D.) diameters, wall thickness, width, height, and general cross-sectional dimensions or extrusions.

| 1 | 2 | 3 | |

Drawing Designation | E1 | E2 | E3 | |

Dimensions (in millimeters) | ||||

Over | Through | |||

0.0 | 1.5 | ±0.15 | ±0.25 | ±0.40 |

1.5 | 2.5 | 0.20 | 0.35 | 0.50 |

2.5 | 4.0 | 0.25 | 0.40 | 0.70 |

4.0 | 6.3 | 0.35 | 0.50 | 0.80 |

6.3 | 10.0 | 0.40 | 0.70 | 1.00 |

10.0 | 16.0 | 0.50 | 0.80 | 1.30 |

16.0 | 25.0 | 0.70 | 1.00 | 1.60 |

25.0 | 40.0 | 0.80 | 1.30 | 2.00 |

40.0 | 63.0 | 1.00 | 1.60 | 2.50 |

63.0 | 100.0 | 1.30 | 2.00 | 3.20 |

| 1 | 2 | 3 | |

Drawing Designation | E1 | E2 | E3 | |

Dimensions (in millimeters) | ||||

Over | Through | |||

0.000 | 0.060 | ±0.006 | ±0.010 | ±0.015 |

0.060 | 0.100 | 0.008 | 0.014 | 0.020 |

0.100 | 0.160 | 0.010 | 0.016 | 0.027 |

0.160 | 0.250 | 0.014 | 0.020 | 0.031 |

0.250 | 0.390 | 0.016 | 0.027 | 0.039 |

0.390 | 0.630 | 0.020 | 0.031 | 0.051 |

0.630 | 0.980 | 0.027 | 0.039 | 0.063 |

0.980 | 1.570 | 0.031 | 0.051 | 0.079 |

1.570 | 2.480 | 0.039 | 0.063 | 0.098 |

2.480 | 3.940 | 0.051 | 0.079 | 0.126 |

*Note: Supplier and user should agree on tolerances on dimensions above 100mm (3.94 in.). General cross-sectional dimensions below 1mm (0.04 in.) are impractical

In general, softer materials and those requiring a post-cure need greater tolerances.

ARPM Table 38 – Cross Section

Tolerances on cross-sectional dimensions of irregular and cored shapes of extruded, expanded, closed-cellular rubber. Class 1 tolerances in the table below are recommended only for high-volume, tight products for automotive applications.

ARPM Class | 1* | 2 | 3 | |

Drawing Designation | BEC1 | BEC2 | BEC3 | |

Millimeters | Tolerance | |||

Over | Through | |||

0.00 | 6.30 | ±0.40 | ±0.50 | ±0.63 |

6.30 | 12.50 | 0.63 | 1.00 | 1.25 |

12.50 | 25.00 | 1.25 | 2.00 | 2.50 |

25.00 | 40.00 | 2.00 | 3.20 | 4.00 |

40.00 | & over mult.by | 0.06 | 0.08 | 0.10 |

ARPM Class | 1* | 2 | 3 | |

Drawing Designation | BEC1 | BEC2 | BEC3 | |

Inches | Tolerance | |||

Over | Through | |||

0.000 | 0.250 | ±0.016 | ±0.020 | ±0.025 |

0.250 | 0.500 | 0.025 | 0.040 | 0.050 |

0.500 | 1.000 | 0.050 | 0.080 | 0.100 |

1.000 | 1.600 | 0.080 | 0.125 | 0.160 |

1.600 | & over mult.by | 0.060 | 0.080 | 0.100 |

*Class 1 tolerances should not be applied to the softer grades of material – below 63 kPa (9 psi) compression deflection.

ARPM Table 39 – Cross-Sectional Dimension (Width, Thickness, or Diameter)

Tolerances on cross-sectional dimensions of cored, rectangular, or other regular shapes of extruded, expanded, closed-cellular rubber.

ARPM Class | 1 | 2 | 3 | |

Drawing Designation | BEC1 | BEC2 | BEC3 | |

Millimeters | Tolerance | |||

Over | Through | |||

3.20 | 12.50 | ±0.80 | ±0.80 | ±1.00 |

12.50 | 25.00 | 1.25 | 1.25 | 2.00 |

25.00 | 50.00 | 1.60 | 2.00 | 4.00 |

50.00 | 80.00 | 2.50 | 3.20 | 5.00 |

80.00 | & over mult. by | 0.06 | 0.08 | 0.10 |

ARPM Class | 1 | 2 | 3 | |

Drawing Designation | BEC1 | BEC2 | BEC3 | |

Inches | Tolerance | |||

Over | Through | |||

0.125 | 0.500 | ±0.032 | ±0.032 | ±0.040 |

0.500 | 1.000 | 0.050 | 0.050 | 0.080 |

1.000 | 2.000 | 0.063 | 0.080 | 0.160 |

2.000 | 3.150 | 0.100 | 0.125 | 0.200 |

3.150 | & over mult. by | 0.060 | 0.080 | 0.100 |

Get Help with Extruded Rubber Tolerances

Do you need help with extruded rubber tolerances? Elasto Proxy is a rubber fabricator and distributor that supplies extruded rubber products as coils, cut lengths, and finished gaskets. When you work with us, we can provide design assistance. The tolerances that you’ve read about in this article aren’t the only ones from the ARPM, and molded rubber products have their own tolerance tables.