Bulb Trim Basics

A bulb trim seal is a rubber gasket that provides sealing and insulation for doors or hatches with radiused corners. This type of industrial rubber product is sometimes called a…

A bulb trim seal is a rubber gasket that provides sealing and insulation for doors or hatches with radiused corners. This type of industrial rubber product is sometimes called a…

Edge trim protects exposed edges and the people who come into contact with them. Trim seals, as edge trim is sometimes called, also provides a finished appearance to surfaces such…

Extruded rubber seals support complex cross-sections and have a smooth surface finish. Examples include bulb, lip, door, and accordion seals. These aren’t the only types of extruded rubber products, but…

Do you need to seal rounded corners against wind, water, dust, or dirt? Bulb trim seals are industrial rubber products that provide sealing and insulation for machine doors, vehicle hatches, and equipment enclosures. They’re designed to seal rounded corners and have separate bulb and retainer sections. Each of these sections can use a different material and have a different durometer or hardness.

Do you need to seal rounded corners against wind, water, dust, or dirt? Bulb trim seals are industrial rubber products that provide sealing and insulation for machine doors, vehicle hatches, and equipment enclosures. They’re designed to seal rounded corners and have separate bulb and retainer sections. Each of these sections can use a different material and have a different durometer or hardness.

With bulb trim, the bulb section compresses to form a seal when the door, hatch, or enclosure is closed. The trim or retainer section attaches to a flange or substrate. To choose bulb trim for your application, you need to specify the bulb size, bend radius, and flange thickness. By choosing the right bulb size, you can avoid over-compression. The right bend radius and flange thickness help to avoid kinking and leakage. (more…)

Do you need thermal, acoustic, or thermal-acoustic insulation for forestry, mining, construction, or other types of mobile equipment? Maybe you need cabin flooring or floormats instead. The Elasto Bag, a sack full of samples from Elasto Proxy, contains sealing and insulation that you can see for yourself and hold in your hands. It’s easy to request an Elasto Bag, but what’s inside when you get it?

Do you need thermal, acoustic, or thermal-acoustic insulation for forestry, mining, construction, or other types of mobile equipment? Maybe you need cabin flooring or floormats instead. The Elasto Bag, a sack full of samples from Elasto Proxy, contains sealing and insulation that you can see for yourself and hold in your hands. It’s easy to request an Elasto Bag, but what’s inside when you get it?

The Elasto Bag contains at least nine samples of sealing and insulation. (We can also include samples of edge trim, bulb trim, or D-shaped profiles with adhesives if you need them). Let’s take a look at what’s inside the Elasto Bag so that you’ll understand what you have or can get. Along the way, you’ll see links where you can download product specifications. (more…)

Vibration dampers dissipate the energy that causes resonant vibrations in built structures. Vibration, a back-and-forth movement or oscillation, produces structure-borne noise in machine enclosures, engine bays, generator sets, heavy trucks,…

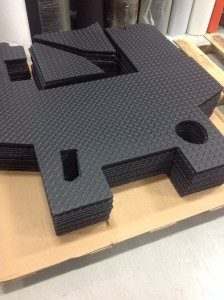

Rubber floor mats for mobile equipment protect cabin floors from damage and operators from slip-and-fall hazards. Rubber flooring that’s laminated to acoustic insulation also absorbs noise from the engine compartment, which is often directly below the cab where the operator sits. Rubber matting can even be used as a kick-plate to protect cabin walls from contact with an operator’s boots.

Rubber floor mats for mobile equipment protect cabin floors from damage and operators from slip-and-fall hazards. Rubber flooring that’s laminated to acoustic insulation also absorbs noise from the engine compartment, which is often directly below the cab where the operator sits. Rubber matting can even be used as a kick-plate to protect cabin walls from contact with an operator’s boots.

For mobile equipment manufacturers, choosing the right type of cabin flooring is an important design consideration. The metal floors that are used inside a cab are durable, but operators track mud, snow, dirt, and water inside. Rubber floor mats can protect these metal surfaces from rust, corrosion, and scratching. Sheet metal flooring can become slippery, but rubber surfaces can offer surer footing.

As manufacturers are discovering, rubber floor mats are part of a complete cabin solution that promotes operator safety and equipment performance. By understanding how rubber flooring is designed and made, manufacturers can determine if a custom-fabricated solution is the right choice. For starters, however, engineers may want to compare rubber to other flooring materials. (more…)

Custom cab insulation absorbs sound and provides a finished appearance to mobile equipment interiors. This acoustic insulation can be cut by hand and applied with spray adhesives, but that process is expensive, wasteful, and even hazardous to human health. Plus, manual cutting can result in cabin insulation that’s unappealing. Buyers who see mis-cuts may question the quality of your overall equipment design.

Custom cab insulation absorbs sound and provides a finished appearance to mobile equipment interiors. This acoustic insulation can be cut by hand and applied with spray adhesives, but that process is expensive, wasteful, and even hazardous to human health. Plus, manual cutting can result in cabin insulation that’s unappealing. Buyers who see mis-cuts may question the quality of your overall equipment design.

As mobile equipment manufacturers are discovering, there’s a better way to design and build quieter cabs. Custom-fabricated insulation that’s waterjet cut creates straight lines and chamfered angles. There’s less material waste, reduced cutting times, and closer control of material usage. Engineers can also get design assistance and help with material selection. Installers can avoid messy, toxic spray adhesives.

Parts marking, kitting, and packaging provide benefits, too. By taking a closer look at how custom-fabricated cab insulation is made, you can determine if it’s the right choice for your company. (more…)

Window channels are rubber gaskets that hold window glass in place and help to secure window frames. They also eliminate rattling and provide protection against wind, water, dust, and debris. Applications for window channels include mobile equipment, defense, medical and health, stainless steel and food equipment, infrastructure, and aerospace.

Window channels are rubber gaskets that hold window glass in place and help to secure window frames. They also eliminate rattling and provide protection against wind, water, dust, and debris. Applications for window channels include mobile equipment, defense, medical and health, stainless steel and food equipment, infrastructure, and aerospace.

For engineers and product designers, window channel selection begins by understanding the types of products that are available. It’s also important to define your application requirements and to compare product specifications. In this article from Elasto Proxy, you’ll learn how to select window channels that provide the sealing and insulation you need. (more…)

There are four common shapes for extruded rubber seals. Do you know which shape is the right choice for your gasket application? Engineers and seal designers can choose P-shapes, D-shapes, E-shapes, and lip seals. Purchasing agents can either order cut lengths or buy spliced gaskets.

There are four common shapes for extruded rubber seals. Do you know which shape is the right choice for your gasket application? Engineers and seal designers can choose P-shapes, D-shapes, E-shapes, and lip seals. Purchasing agents can either order cut lengths or buy spliced gaskets.

In this article from Elasto Proxy, you’ll learn when to choose and how to use the four common shapes for extruded rubber seals. We also invite you to stay tuned for a series of short videos that will explain what you need to know about P-seals, D-seals, E-seals, and lip seals. (more…)