The best sound insulation for tractors and agricultural equipment is pre-cut, has an adhesive backing, and comes in a kit with all the parts a worker needs to install at a stop on the assembly line. Typically, these noise-reducing parts include the headliner, acoustical panels, and floor mats. Kits can also include door gaskets and window channels, both of which combine sealing with insulation.

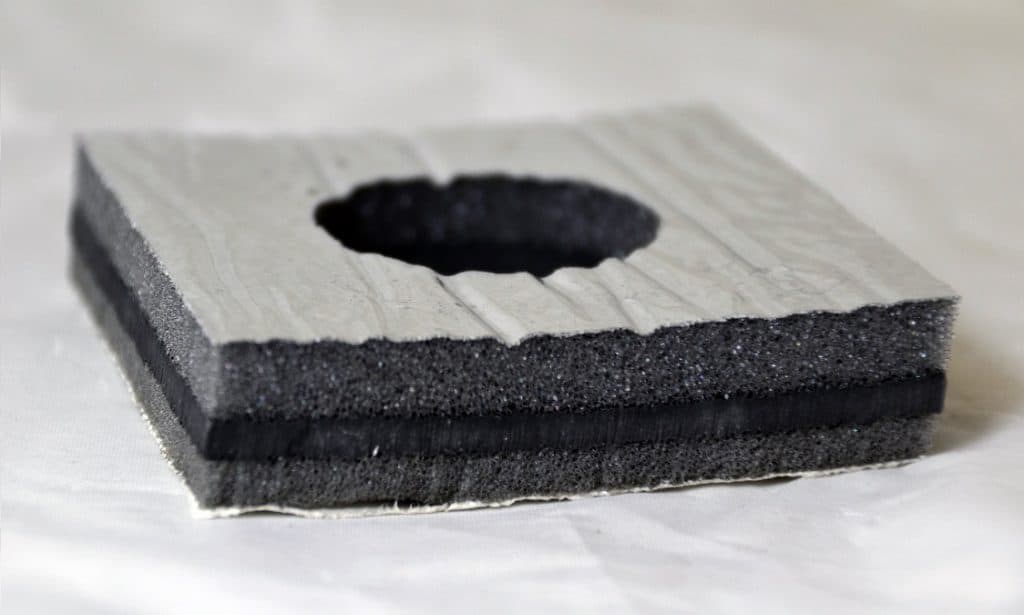

In addition, the best sound insulation provides agricultural equipment manufacturers with a choice of acoustical materials in various colors, styles, and thicknesses. These foams, foils, and facings can be combined into sandwich-style structures that absorb, block, and/or dampen noise and vibration. Ready-to-install cabin insulation can also be packaged in order of assembly.

How to Find the Best Sound Insulation

Elasto Proxy provides the best sound insulation for agricultural equipment like tractors, combines, and harvesters because we help you save time and money while improving product quality and operational efficiency. Contact us for a quote or keep reading to learn about the value we provide through the following services.

- Material Selection

- Water Jet Cutting

- Adhesive Taping

- Lamination

- Kitting and Custom Packaging

Material Selection

Elasto Proxy offers a wide selection of acoustical materials and can help you make the best choice for your agricultural equipment. For example, let’s say you need to install sound-absorbing insulation between the roof of a tractor cabin and a thermoformed headliner. Because this insulation is hidden from view, we may suggest an unfaced acoustical foam made of polyester or polyurethane.

If this sound insulation is visible, however, we can offer you a choice of facings that meet your aesthetic requirements. For example, if you don’t want a perforated material, we can provide an embossed felt headliner instead. Facing materials can also absorb a specific frequency or range of frequencies while matching the larger color scheme for your product design.

Water Jet Cutting

Some equipment manufacturers still buy insulation in sheets or rolls and cut materials by hand, typically with a knife and a carboard template. This approach is time-consuming and results in material waste from mis-cuts. Then, as the edges of the template are whittled away, part dimensions become imprecise. If there are gaps between mating parts, noise has a pathway to enter the cabin.

Elasto Proxy uses water jet equipment to cut materials. There’s no tooling to wait for or pay for, and we can nest your parts to maximize material yields. Water jet cutting produces edges, angles, holes, and notches with precision. Plus, this computer-controlled process replaces cardboard templates with digital files while letting your skilled workers focus on higher-value tasks than hand cutting.

Adhesive Taping

Tractor and ag equipment manufacturers who install insulation with liquid adhesives add costs and introduce risks. To avoid overspray, workers protect or mask specific areas of the cabin. Setup may also involve mixing two-part adhesives and adjusting handheld dispensers. Many liquid adhesives raise environmental health and safety concerns, and cleanups can be time-consuming.

Elasto Proxy can apply pressure-sensitive adhesive (PSA) tapes to the acoustic insulation that we water jet cut. These PSA tapes provide a peel-and-stick solution that’s fast and easy to install. Many different PSA tapes are available, and Elasto Proxy can help you to choose one for temporary or permanent fastening, and that can withstand specific environmental conditions.

Lamination

Some noise control applications need more than one type of noise control material. For example, the insulation that’s used under a tractor may need a foil backing. Similarly, the rubber flooring inside the cabin of a combine or harvester may not stop enough noise. By laminating different insulating materials together, Elasto Proxy can provide you with a complete solution.

For example, FM-500-60-ZM flooring includes acoustical foam that’s bonded to a sound barrier. The top of this barrier material features a diamond plate design that can catch water from an operator’s boots while providing a non-slip surface. For cabin interiors, Elasto Proxy can also laminate acoustical materials that meet specific flammability requirements or ASTM specifications.

Kitting and Custom Packaging

Finally, Elasto Proxy offers kitting and custom packaging for greater efficiency. For example, let’s say there’s a stop on the assembly line where a worker installs a headliner, 15 acoustical side panels, and rubber flooring. Elasto Proxy can produce each part, kit them together, and package everything so that the part to install first is on top, the part to install next is beneath it, and so on.

Assembly efficiency isn’t the only benefit. Kitting reduces the number of SKUs, each of which costs thousands of dollars to maintain. With a kit, there’s only one SKU to order, receive, store, pick, and pay for. There’s also less risk of picking the wrong parts or installing them in the wrong order. A kit can also travel from your receiving dock to assembly line and bypass warehousing and picking.

Are you ready to get the best sound insulation for tractors and agricultural equipment? Choose Elasto Proxy.