In this case study, you’ll learn how Elasto Proxy used water jet cutting to fabricate cost-effective parts for forestry equipment. From prototyping to production, water jet cutting is meeting the requirements of a leading mobile equipment manufacturer.

Forestry equipment such as log skidders, feller bunchers, forwarders, delimbers, and harvesters are built for off-road conditions. Steep terrain, mud, and snow won’t stop these wheeled or tracked machines when they’re driven by skilled operators. Cab safety and comfort matters, too, and equipment owners recognize the importance of protecting personnel and machinery. That’s why when buyers compare forestry equipment, they reward manufacturers that meet demanding requirements.

The big diesel engines that power forestry equipment are loud, but dampening engine noise isn’t just about operator comfort. Noisy machinery can cause hearing loss, affect worker safety, and result in violations that carry fines and other penalties. Loud, unwanted noises can also affect buyer perceptions about equipment quality. Yet engine sounds aren’t the only reason for cab sealing and insulation. Mud or snow from an operator’s boots gets tracked into the cab, and water can pool or freeze on the floor.

Technical Design and Custom Fabrication

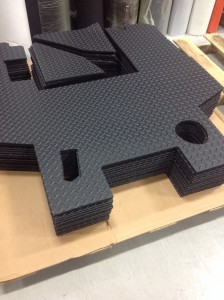

When a manufacturer of forestry equipment redesigned an operator cab, the company needed all new components for the interior. Importantly, these cab parts included acoustic insulation for dampening engine sounds and rubber floor mats for protecting the vehicle’s flooring. As an experienced provider of sealing and insulation solutions to the mobile equipment industry, Elasto Proxy applied its technical design and custom fabrication expertise to solve several challenges.

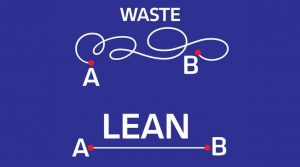

Like other manufacturers, forestry equipment companies need cost-effective parts that support design revisions and tight tolerances. Die cutting can convert sheets of acoustic foam and rubber matting into precise parts, but this production method requires metal tools called dies. Tooling increases project costs, and a new die is required whenever a part design changes. For manufacturers that need prototypes of many different parts across multiple iterations, waiting for tooling can also extend project timelines.

That’s why Elasto Proxy uses water jet cutting to convert sheets of rubber, plastic, and elastomeric materials into cab components such as floor mats and acoustic insulation. Unlike die cutting, water jet cutting doesn’t require special tooling. This contains project costs and speeds prototyping. Instead of paying for and then waiting for metal dies to arrive, Elasto Proxy programs its water jet cutting machine. In fact, our skilled production personnel can use your CAD files to capture all of the part details and dimensions.

Rubber Cab Parts From Prototyping to Production

Water jet cutting didn’t just save the forestry equipment manufacturer time and money on new cab parts. This custom fabrication technique also supported the company’s engineering team, which revised the cab’s design several times. Ultimately, Elasto Proxy cut 21 different parts. There were four iterations for each design, which means that over 80 prototypes were required. With die cutting, this project would have required 80 different dies – a substantial cost just for tooling.

At Elasto Proxy, water jet cutting directs high-pressure jets of 50,000 psi towards an X-Y axis table with a 5’ x 10’ cutting surface. For smaller parts, our water jet machine can make cuts down to 1/2” x 1/2”. With gaskets, we can create holes with diameters as small as 0.01”. Water jet cutting supports quick-turn prototyping, but it’s also ideal for parts production. Now that the cab redesign for the forestry equipment is complete, Elasto Proxy is water jet cutting cab parts that support assembly line operations.

How Can We Help You?

Do you need cab parts for mobile equipment? Would you like to learn more about how water jet cutting eliminates tooling costs and supports project timelines? From prototyping to production, Elasto Proxy has the technical knowledge and application expertise. How can we help you? Please contact us.