Acrylic foam tapes provide durable bonding, superior sealing, and effective insulation. Learn about the advantages of these PSA tapes, how technical buyers and product designers select them, and how different types of acrylic foams tapes are used with infrastructure and mobile equipment.

Acrylic foam tapes provide durable bonding, superior sealing, and effective insulation. Learn about the advantages of these PSA tapes, how technical buyers and product designers select them, and how different types of acrylic foams tapes are used with infrastructure and mobile equipment.

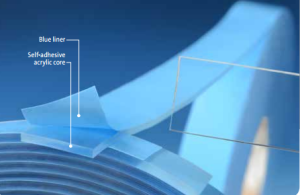

Acrylic foam tapes provide dependable, cost-effective bonding, sealing, and insulation for infrastructure and mobile equipment. These double-sided industrial tapes have an acrylic foam core and use a high-strength pressure-sensitive adhesive (PSA) with a release liner. The foam core distributes stress evenly, and the PSA provides permanent attachment without metal fasteners, messy liquid adhesives, or time-consuming setup or curing processes. Are acrylic foam tapes right for your application? Let’s take a look.

Advantages of Acrylic Foam Tapes

Installers like acrylic foam tapes because they don’t require extensive surface preparation or cleanup, and support peel-and-stick application. Inventory managers like that the release liners protect the PSA tapes during extended storage. Acrylic foam tapes also strengthen product designs because of their outstanding adhesive and viscoelastic properties. They attach readily and reliably to dissimilar materials such as glass. These plastic foam tapes also resist deformation, absorb shock, isolate vibration, and dampen noise.

Acrylic foam tapes provide outstanding shear adhesion, too. Shear adhesion describes the ability of a tape to resist static forces that are applied in the same plane as the backing. Typically, shear adhesion is expressed as the time required for a given weight to cause a unit of tape to loosen from a vertical panel. In applications such as architectural panels and truck panels then, the shear adhesion of acrylic foam tapes supports not just the product’s design, but quality and safety.

If acrylic foam tapes are right for your application, which type of tape should you select?

Acrylic Foam Tapes and Product Design

Technical buyers and product designers can choose acrylic foam tapes that are clear, gray, white, or dark in color. Some clear acrylic foam tapes are so transparent that they’re nearly invisible when applied to a glass substrate. Other PSA tapes are gray, white, or black so that they can match or closely match the color of the substrate. Acrylic foam tapes differ in terms of thickness, too. All of these factors are important, but buyers and designers must also consider surface energy and application environment.

Different materials have different surface energies, and that means a tape that’s right for one type of substrate might not be right for another. To ensure optimal attachment, the adhesive’s surface energy must be equal to or lower than the surface energy of the substrate. Metals and glasses have relatively high surface energies. PVC and polyester are medium surface energy materials. Buyers and designers must also consider environmental factors such as maximum temperature, sunlight, and weathering.

Acrylic Foam Tape Types and Applications

Elasto Proxy custom-fabricates acrylic foam tapes for both interior and exterior applications.

- Transparent, double-sided, acrylic foam tapes are used in infrastructure applications such as security glass, bath and shower hardware, appliance components, and polycarbonate bonding.

- Grey, double-sided, acrylic foam tapes are used in skin bonding and roof bonding for mobile equipment such as buses, trucks, and trailers.

- White, double-sided, acrylic foam tapes are used for roof panel bonding on truck cabs, and for mirror mounting. Infrastructure applications include hinges, handles, and control elements for appliances.

- Dark, double-sided, acrylic foam tapes are used in window shade side panels, elevator panels, and shelving and furniture. Additional applications include ceramic cooktop bonding.

All of these plastic foam tapes provide durable, long-lasting adhesion to substrates with high surface energy. They also exceed industry standards for shear strength and bonding, even at elevated temperatures.

How Can We Help You?

From tape selection and technical assistance to custom fabrication and inventory management, Elasto Proxy is ready to help you add acrylic foam tapes to your product designs. Would you like to learn more? Please contact us for information. We will close for the winter holidays at noon on Thursday, December 24, 2015 and reopen on Monday, January 4, 2015.

Acrylic foam tapes provide durable bonding, superior sealing, and effective insulation. Learn about the advantages of these PSA tapes, how technical buyers and product designers select them, and how different types of acrylic foams tapes are used with infrastructure and mobile equipment.

Acrylic foam tapes provide durable bonding, superior sealing, and effective insulation. Learn about the advantages of these PSA tapes, how technical buyers and product designers select them, and how different types of acrylic foams tapes are used with infrastructure and mobile equipment.