NSF/ANSI Standard 61 establishes health-related requirements for rubber seals and gaskets used in potable water systems. Learn how NSF/ANSI 61 can affect your project’s costs, how there’s a difference between NSF/ANSI 61 complaint and NSF/ANSI 61 approved materials, and how water jet cutting and infrared splicing create high-quality custom rubber gaskets.

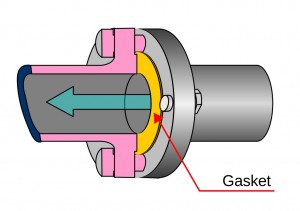

Custom rubber gaskets that are used in drinking water systems need to be free from chemicals that can leach into water supplies and affect human health or cause unpleasant tastes and odors. Additives such as plasticizers, antioxidants, and solvents are designed to impart desirable material properties, but can react unfavorably with water treatment chemicals such as chlorine. Leachates from rubber gasket materials can also affect the formation of fungi, algae, and bacteria.

Technical buyers and product designers whose organizations specialize in drinking water systems are familiar with these problems already. Building and construction companies also need to understand the risks – and the requirements for mitigating them. By choosing a gasket fabricator that understands requirements such as NSF/ANSI 61, you can source the right materials and receive high-quality plumbing components that support your projects.

What Is NSF/ANSI Standard 61?

NSF/ANSI Standard 61 establishes health-related requirements for drinking water components such as rubber seals and gaskets. Developed by NSF International (formerly the National Sanitary Foundation) and adopted by the American Standards Institute (ANSI), NSF/ANSI 61 is a set of standards that you need to know about if your company supplies products that come into contact with potable water, or supports the production of potable water through filtration, disinfection, and distribution.

NSF/ANSI Standard 61 establishes health-related requirements for drinking water components such as rubber seals and gaskets. Developed by NSF International (formerly the National Sanitary Foundation) and adopted by the American Standards Institute (ANSI), NSF/ANSI 61 is a set of standards that you need to know about if your company supplies products that come into contact with potable water, or supports the production of potable water through filtration, disinfection, and distribution.

In the United States, failure to meet the requirements of NSF / ANSI Standard 61 can result in lost bids, fines, or legal action. Plumbers, general contractors, and building and construction companies that install non-compliant components may be required to remove and replace plumbing devices. Health Canada, the federal department that’s responsible for promoting Canadians’ health, strongly recommends the use of drinking water components that meet standards from accredited organizations like the NSF.

How to Select NSF/ANSI 61 Gasket Materials

As a technical buyer or product designer, it’s important to understand that there’s a difference between NSF/ANSI 61 compliant materials and NSF/ANSI 61 approved materials. NSF/ANSI 61 compliant materials are tested by an independently-accredited laboratory according to the published NSF/ANSI 61 Standard. NSF/ANSI 61 certified materials are tested by the NSF itself as part of the organization’s lab and testing services. NSF tested materials that meet the NSF/ANSI 61 Standard are also known as NSF listed.

As a technical buyer or product designer, it’s important to understand that there’s a difference between NSF/ANSI 61 compliant materials and NSF/ANSI 61 approved materials. NSF/ANSI 61 compliant materials are tested by an independently-accredited laboratory according to the published NSF/ANSI 61 Standard. NSF/ANSI 61 certified materials are tested by the NSF itself as part of the organization’s lab and testing services. NSF tested materials that meet the NSF/ANSI 61 Standard are also known as NSF listed.

Which type of gasket materials (NSF/ANSI complaint or NSF/ANSI certified) does your project require? That’s an important question, but it’s not the only one to ask during compound selection. What is the application environment? How often will you replace parts? Do you need to support both hot and cold water service? For outdoor applications, NSF/ANSI 61 EPDM rubber provides excellent resistance to heat, ozone, and cracking. EPDM rubber is also water-resistant and also supports a wide temperature range.

How to Select a Custom Fabricator for NSF/ANSI 61 Gaskets

Specialty elastomers can cost more than rubber materials that are used in other applications. So it’s important to minimize material waste, and to ensure that fabricated gaskets are cut accurately and cleanly. Water jet cutting makes fine, fast, accurate cuts without dies or tooling charges. Infrared splicing supports large seal sizes and is less expensive than molding.

Application experience is also important. That’s why when a manufacturer of water filtration systems needed a high-quality sealing solution for its gates, the company choose Elasto Proxy. Today, Elasto Proxy stocks this custom rubber seal at our warehouse in Newmarket, Ontario, and ships quantities according to the manufacturer’s sales forecasts. You can learn more by downloading the case study.