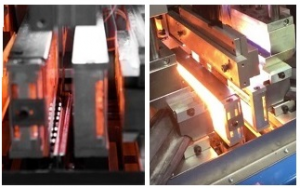

Hot splicing uses heat, pressure, and a film splice to join the ends of rubber profiles into bonded gaskets. This joining technique uses either a conventional heating source or infrared (IR) light and polyethylene (PE) film. Hot splicing creates strong bonds at the molecular level and generally provides better results than vulcanization, a bonding technique that uses uncured rubber instead of a film splice.

Hot splicing uses heat, pressure, and a film splice to join the ends of rubber profiles into bonded gaskets. This joining technique uses either a conventional heating source or infrared (IR) light and polyethylene (PE) film. Hot splicing creates strong bonds at the molecular level and generally provides better results than vulcanization, a bonding technique that uses uncured rubber instead of a film splice.

Choosing the best way to bond rubber gaskets can be a complex decision, however. The profile material is just one of many considerations. You also need to consider the size and shape of the seal, production quantities and costs, and the way that lengths of rubber are cut. In addition, it’s important to inspect and install your gaskets properly to ensure reliable sealing and prevent avoidable waste.

Is hot splicing better than vulcanizing for the rubber gaskets that you need? Let’s take a closer look.

Vulcanized Gaskets

Vulcanizing uses heat, pressure, and uncured rubber to join the ends of sponge or solid profiles. Applications include O-rings, tubing, and rubber gaskets that need a space for the free-flowing passage of air. Vulcanization is best-suited for low-volume quantities instead of high-volume production. This splicing technique is also a good choice for joining lower-quality cuts like those made with guillotine cutting.

Vulcanizing uses heat, pressure, and uncured rubber to join the ends of sponge or solid profiles. Applications include O-rings, tubing, and rubber gaskets that need a space for the free-flowing passage of air. Vulcanization is best-suited for low-volume quantities instead of high-volume production. This splicing technique is also a good choice for joining lower-quality cuts like those made with guillotine cutting.

With vulcanization, the uncured rubber compound that’s used is the same type of elastomer as the profile itself. First, the uncured rubber is applied to the length of profile. The ends are pressed together, and the joint is placed into a hot mold. The uncured compound flows into any gaps and fills them. The result is a strong bond between profile surfaces. When bonding is complete, cooling is required.

Hot Spliced Gaskets

Unlike vulcanization, hot splicing always uses a PE splice instead of an uncured rubber compound that’s made of the same material as the profile itself. Hot splicing also requires clean, straight cuts such as those made with water jet cutting or abrasive water jet cutting. Ultimately, these smooth edges are easier-to-bond. Automated cutting is also faster than manual cutting and offers greater consistency and accuracy.

Unlike vulcanization, hot splicing always uses a PE splice instead of an uncured rubber compound that’s made of the same material as the profile itself. Hot splicing also requires clean, straight cuts such as those made with water jet cutting or abrasive water jet cutting. Ultimately, these smooth edges are easier-to-bond. Automated cutting is also faster than manual cutting and offers greater consistency and accuracy.

Compared to vulcanization, hot splicing is better for higher-volume quantities. Most hot spliced joints are 90° but this bonding technique also supports 45° miter cuts and endless gaskets. The type of profile – sponge or solid – usually determines whether conventional hot splicing or IR splicing is used. Some materials, such as silicone, support traditional hot splicing but not infrared splicing.

IR splicing is a good choice for sponge rubber profiles because infrared light won’t burn the elastomer. Infrared splicing equipment can also accommodate very large profiles, such as the bonded gaskets that are used as gate seals in water filtration systems. IR splicing also requires significantly less trimming, a post-production activity that’s performed manually. This video provides a demonstration.

Inspecting and Installing Spliced Gaskets

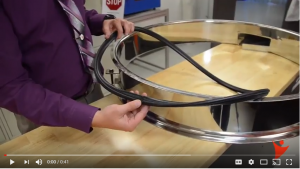

If hot splicing is the right choice for your application, you’ll need to follow the proper installation and inspection methods. When installing a spliced gasket onto your product, always start with the joint. Then move six inches to the left and six inches to the right, as this video shows. By securing the joint, you can then continue to install the gasket without breakage.

If hot splicing is the right choice for your application, you’ll need to follow the proper installation and inspection methods. When installing a spliced gasket onto your product, always start with the joint. Then move six inches to the left and six inches to the right, as this video shows. By securing the joint, you can then continue to install the gasket without breakage.

Inspecting a spliced gasket is simple. Hold the bonded gasket on each side and pull away from the joint. If you don’t see a break, your gasket is sealed and ready to install. Do not inspect the gasket by folding it at the joint. Doing so will break the rubber gasket in half. Folding the gasket in this way is unrealistic; it’s not how your seal will operate.

Get the Bonded Gaskets You Need

Elasto Proxy uses hot splicing, vulcanizing, cold bonding, and molding to create bonded gaskets. We also use water cutting and abrasive water jet cutting so that the edges of rubber profiles are smooth, straight, and easy-to-bond. If you need hot spliced gaskets, we offer both conventional hot splicing and infrared splicing. To get the bonded gaskets that you need, ask Elasto Proxy.