Does your seal design use the right tolerances? When Elasto Proxy performs a design review, we check the tolerances on the drawing, blueprint, or CAD file you share. Many engineers are used to working with metal parts, but rubber parts need different tolerances than metal ones.

There are two reasons for this.

- Rubber is processed – molded or extruded – with different tools and equipment.

- Rubber is more sensitive to changes in temperature and humidity.

So, if you’re designing a rubber seal, please don’t add metal tolerances to your drawing, blueprint, or CAD file. If you do, you’ll need to revise your design because metal tolerances aren’t possible with rubber parts like seals and gaskets.

But which tolerances do you need to use instead? That’s what this article explains.

The Rubber Handbook: Tolerance Tables and Precision Levels

The Association for Rubber Products Manufacturers Association (ARPM) publishes a Rubber Handbook with the tolerances that engineers need to use with rubber products. Because the ARMA used to be called the Rubber Manufacturers Association (RMA), you might hear this guide called the RMA Handbook instead. Regardless, you’ll need to follow this guide, which lists tolerances in tables.

You can buy the Rubber Handbook yourself, or you ask Elasto Proxy to send you relevant sections when choose us as your rubber fabricator. You can also refer to the tolerance tables that you’ll find listed below. These are just a few of the tolerance tables in the Rubber Handbook, which contains length and separate chapters for molded, extruded, lathe-cut, and cellular rubber.

Within these chapters, each table contains drawing designations that indicate the level of precision. Rubber products with higher precision cost more, but some applications (such as aerospace) may require them. For extruded rubber products, the Rubber Handbook also contains tables for specific manufacturing operations. Because Elasto Proxy cuts and bonds extrusions into seals, we’ve included a few tables below.

Molded Rubber Products: Part Tolerances for Your Seal Design

The Rubber Handbook contains four drawing designations for molded rubber products.

- A1 – High Precision

- A2 – Precision

- A3 – Commercial

- A4 – Basic

We’ve listed these tolerances below so that you can add them to the seal designs you send to Elasto Proxy.

A1 – High Precision

Size (mm) | Fixed | Closure | Size (inches) | Fixed | Closure | ||

Over | Through | Over | Through | ||||

0 | 10 | ±0.10 | ±0.10 | 0.000 | 0.400 | ±0.004 | ±0.005 |

10 | 16 | 0.13 | 0.16 | 0.400 | 0.630 | 0.005 | 0.006 |

16 | 25 | 0.16 | 0.20 | 0.630 | 1.000 | 0.006 | 0.008 |

25 | 40 | 0.20 | 0.25 | 1.000 | 1.600 | 0.008 | 0.010 |

40 | 63 | 0.25 | 0.32 | 1.600 | 2.500 | 0.010 | 0.013 |

63 | 100 | 0.32 | 0.40 | 2.500 | 4.000 | 0.013 | 0.016 |

100 | 160 | 0.40 | 0.50 | 4.000 | 6.300 | 0.016 | 0.020 |

A2 – Precision

Size (mm) | Fixed | Closure | Size (inches) | Fixed | Closure | ||

Over | Through | Over | Through | ||||

0 | 10 | ±0.16 | ±0.10 | 0.000 | 0.400 | ±0.006 | ±0.008 |

10 | 16 | 0.20 | 0.16 | 0.400 | 0.630 | 0.008 | 0.010 |

16 | 25 | 0.25 | 0.20 | 0.630 | 1.000 | 0.010 | 0.013 |

25 | 40 | 0.32 | 0.25 | 1.000 | 1.600 | 0.013 | 0.016 |

40 | 63 | 0.40 | 0.32 | 1.600 | 2.500 | 0.016 | 0.020 |

63 | 100 | 0.50 | 0.40 | 2.500 | 4.000 | 0.020 | 0.025 |

100 | 160 | 0.63 | 0.50 | 4.000 | 6.300 | 0.025 | 0.032 |

160 | & over multiply by | 0.004 | 0.005 | 6.300 | & over | 0.004 | 0.005 |

A3 – Commercial

Size (mm) | Fixed | Closure | Size (inches) | Fixed | Closure | ||

Over | Through | Over | Through | ||||

0 | 10 | ±0.20 | ±0.32 | 0.000 | 0.400 | ±0.008 | ±0.013 |

10 | 16 | 0.25 | 0.40 | 0.400 | 0.630 | 0.010 | 0.016 |

16 | 25 | 0.32 | 0.50 | 0.630 | 1.000 | 0.013 | 0.020 |

25 | 40 | 0.40 | 0.63 | 1.000 | 1.600 | 0.016 | 0.025 |

40 | 63 | 0.50 | 0.80 | 1.600 | 2.500 | 0.020 | 0.032 |

63 | 100 | 0.63 | 1.00 | 2.500 | 4.000 | 0.025 | 0.040 |

100 | 160 | 0.80 | 1.25 | 4.000 | 6.300 | 0.032 | 0.050 |

160 | & over multiply by | 0.005 | 0.008 | 6.300 | & over | 0.005 | 0.008 |

A4 – Basic

Size (mm) | Fixed | Closure | Size (inches) | Fixed | Closure | ||

Over | Through | Over | Through | ||||

0 | 10 | ±0.32 | ±0.80 | 0.000 | 0.400 | ±0.013 | ±0.032 |

10 | 16 | 0.40 | 0.90 | 0.400 | 0.630 | 0.016 | 0.036 |

16 | 25 | 0.50 | 1.00 | 0.630 | 1.000 | 0.020 | 0.040 |

25 | 40 | 0.63 | 1.12 | 1.000 | 1.600 | 0.025 | 0.045 |

40 | 63 | 0.80 | 1.25 | 1.600 | 2.500 | 0.032 | 0.050 |

63 | 100 | 1.00 | 1.40 | 2.500 | 4.000 | 0.040 | 0.056 |

100 | 160 | 1.25 | 1.60 | 4.000 | 6.300 | 0.050 | 0.063 |

160 | & over multiply by | 0.008 | 0.010 | 6.300 | & over | 0.008 | 0.010 |

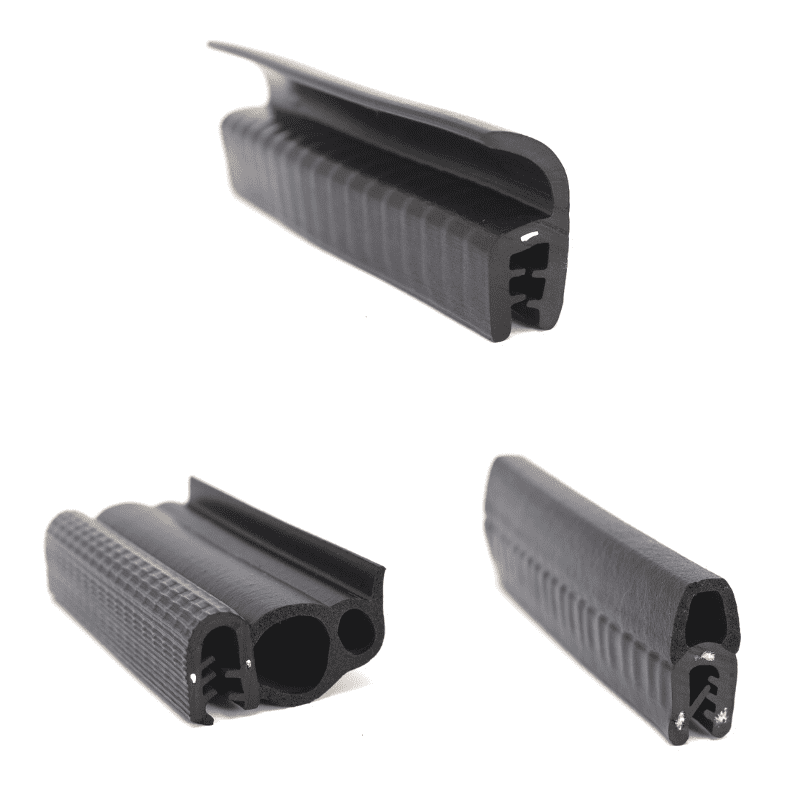

Extruded Rubber Products

The Rubber Handbook contains three drawing designations for extruded rubber products

- E1 – High Precision

- E2 – Precision

- E3 – Commercial

We’ve listed these tolerances below so that you can add them to the seal designs you send to Elasto Proxy.

APRM Class | High Precision | Precision | Commercial | |

Drawing Designation | E1 | E2 | E3 | |

Dimensions (millimeters) |

|

|

| |

Over | Through |

|

|

|

0.0 | 1.5 | ±0.15 | ±0.25 | ±0.40 |

1.5 | 2.5 | 0.20 | 0.35 | 0.50 |

2.5 | 4.0 | 0.25 | 0.40 | 0.70 |

4.0 | 6.3 | 0.35 | 0.50 | 0.80 |

6.3 | 10.0 | 0.40 | 0.70 | 1.00 |

10.0 | 16.0 | 0.50 | 0.80 | 1.30 |

16.0 | 25.0 | 0.70 | 1.00 | 1.60 |

25.0 | 40.0 | 0.80 | 1.30 | 2.00 |

40.0 | 63.0 | 1.00 | 1.60 | 2.50 |

63.0 | 100.0 | 1.30 | 2.00 | 3.20 |

APRM Class | High Precision | Precision | Commercial | |

Drawing Designation | E1 | E2 | E3 | |

Dimensions (inches) |

|

|

| |

Over | Through |

|

|

|

0.000 | 0.060 | ±0.006 | ±0.010 | ±0.015 |

0.600 | 0.100 | 0.008 | 0.014 | 0.020 |

0.100 | 0.160 | 0.010 | 0.016 | 0.027 |

0.160 | 0.250 | 0.014 | 0.020 | 0.031 |

0.250 | 0.390 | 0.016 | 0.027 | 0.039 |

0.390 | 0.630 | 0.020 | 0.031 | 0.051 |

0.630 | 0.980 | 0.027 | 0.039 | 0.063 |

0.980 | 1.570 | 0.031 | 0.051 | 0.079 |

1.570 | 2.480 | 0.039 | 0.063 | 0.098 |

2.480 | 3.940 | 0.051 | 0.079 | 0.126 |

Cut Length Tolerances

Because Elasto Proxy is both a rubber products distributor and a custom fabricator, we can do more than just sell you coils of extruded rubber. With our fast, precise water jet cutting equipment, we can also provide you with cut lengths that we can then bond (splice) into finished seals and gaskets.

The table below shows cut-length tolerances for unspliced extrusions. Because tolerances vary depending on the compound you select and the profile shape that you use, contact us to discuss your application.

APRM Class | 1 Precision | 2 Commercial | 3 Non-Critical | |

Drawing Designation | L1 | L2 | L3 | |

Length (in millimeters) |

|

|

| |

Above | Up to |

|

|

|

0 | 40 | ±0.7 | ±1.0 | ±1.6 |

40 | 63 | 0.8 | 1.3 | 2.0 |

63 | 100 | 1.0 | 1.6 | 2.5 |

100 | 160 | 1.3 | 2.0 | 3.2 |

160 | 250 | 1.6 | 2.5 | 4.0 |

250 | 400 | 2.0 | 3.2 | 5.0 |

400 | 630 | 2.5 | 4.0 | 6.3 |

630 | 1000 | 3.2 | 5.0 | 10.0 |

1000 | 1600 | 4.0 | 6.3 | 12.5 |

1600 | 2500 | 5.0 | 10.0 | 16.0 |

2500 | 4000 | 6.3 | 12.5 | 20.0 |

4000 |

| 0.16% | 0.32% | 0.50% |

APRM Class | 1 Precision | 2 Commercial | 3 Non-Critical | |

Drawing Designation | L1 | L2 | L3 | |

Length (in inches) |

|

|

| |

Above | Up to |

|

|

|

0 | 1.6 | ±0.03 | ±0.04 | ±0.06 |

1.6 | 2.5 | 0.03 | 0.05 | 0.08 |

2.5 | 4.0 | 0.04 | 0.06 | 0.10 |

4.0 | 6.3 | 0.05 | 0.08 | 0.13 |

6.3 | 10.0 | 0.06 | 0.10 | 0.16 |

10.0 | 16.0 | 0.8 | 0.13 | 0.20 |

16.0 | 25.0 | 0.10 | 0.16 | 0.25 |

25.0 | 40.0 | 0.13 | 0.20 | 0.40 |

40.0 | 63.0 | 0.16 | 0.25 | 0.50 |

63.0 | 100.0 | 0.20 | 0.40 | 0.63 |

100.0 | 160.0 | 0.25 | 0.50 | 0.80 |

160.0 |

| 0.16% | 0.32% | 0.50% |

Spliced Length Tolerances

Elasto Proxy offers four splicing (bonding) solutions for cut lengths: cold bonding, film splicing, molding, and vulcanization. The table below shows spliced length tolerances from the Rubber Handbook.

APRM Class | 1 Precision | 2 Commercial | 3 Non-Critical | |

Drawing Designation | L1 | L2 | L3 | |

Length (in millimeters) |

|

|

| |

Above | Up to |

|

|

|

0 | 250 | ±3.2 | ±6.3 | ±7.1 |

250 | 400 | 4.0 | 7.1 | 8.0 |

400 | 630 | 5.0 | 8.0 | 9.0 |

630 | 1000 | 6.3 | 9.0 | 10.0 |

1000 | 1600 | 8.0 | 10.0 | 11.2 |

1600 | 2500 | 10.0 | 11.2 | 12.3 |

2500 | over | 12.5 | 12.5 | 16.0 |

APRM Class | 1 Precision | 2 Commercial | 3 Non-Critical | |

Drawing Designation | L1 | L2 | L3 | |

Length (in inches) |

|

|

| |

Above | Up to |

|

|

|

0 | 10 | ±.13 | ±.25 | ±.28 |

10 | 16 | .16 | .28 | .32 |

16 | 25 | .20 | .32 | .36 |

25 | 40 | .25 | .36 | .40 |

40 | 63 | .32 | .40 | .45 |

63 | 100 | .40 | .45 | .50 |

100 | over | .50 | .50 | .53 |

Remember that spliced length tolerances can vary by compound and shape. When you work with Elasto Proxy, however, we’ll review your part tolerances during our design review process.