The Elasto Proxy Blog is starting the New Year with a quick look back at how we helped readers solve their sealing and insulation challenges in 2017. Whether you’re new to the Blog or a veteran reader of our 275 posts, we hope you’ll enjoy this review and will let us know what you’d like to read about in 2018.

The Elasto Proxy Blog is starting the New Year with a quick look back at how we helped readers solve their sealing and insulation challenges in 2017. Whether you’re new to the Blog or a veteran reader of our 275 posts, we hope you’ll enjoy this review and will let us know what you’d like to read about in 2018.

Here are the top sealing and insulation posts of 2017.

#1 EPDM Rubber for Sealing and Insulation

When is EPDM rubber the right choice for sealing and insulation? In this post, Elasto Proxy covered what engineers need to know about EPDM seals, gaskets, and insulation. Topics included EPDM’s advantages and disadvantages, some comparisons to other elastomers, and information about grades, types, and custom fabrication techniques.

#2 How Silicone Rubber is Used for Sealing and Insulation

When are silicones recommended for sealing and insulation? This family of synthetic elastomers has many desirable properties, but can silicone rubber really meet your requirements? In this post, Elasto Proxy examined specific silicone applications for mobile equipment, defense and aerospace, stainless steel and food equipment, infrastructure, and medical and healthcare.

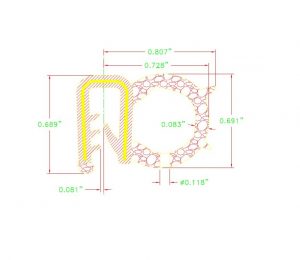

#3 How to Install Edge Trim

Choosing the right type of edge trim is important, but you’ll need to install these industrial rubber products with care. Otherwise, edge trim can buckle or separate. In this “How to” article, Elasto Proxy explained how to select edge trim based on dimensions and material requirements. Readers also learned some best practices for cutting trim seals, and why custom-fabricated edge trim is cost-effective.

#4 Silicone Connectors for Diesel-Powered Vehicles and Equipment

Silicone connectors are molded rubber parts that connect the intake pipes and tubes in diesel-powered vehicles and equipment. In this post, Elasto Proxy described their materials of construction, product specifications, and industry standards and approvals. This article also described the different types of silicone connectors and how custom fabrication adds value to them.

#5 Bulb Trim Seals: Three Measurements You Need to Know

There are three bulb trim seal measurements that engineers need to know: bulb size, bend radius, and flange thickness. Determining the bulb size is a two-process that’s represented by a simple calculation. Getting the bend radius right helps prevent corners that “pop out”, or the formation of recesses that allow the passage of water. The right flange thickness also helps to prevent leakage.

#6 Cab Insulation for Mobile Equipment: Head Liners, Side Panels, Door Panels

Cab insulation for mobile equipment absorbs sound and provides a finished appearance to cabin interiors. To get the best head liners, side panels, and door panels, engineers may need design assistance and help with material selection. As this post explains, value-added services such as water jet cutting, taping, kitting, parts marking, and packaging can save mobile equipment manufacturers time and money.

Learn More

#7 How to Install Locking Gaskets

Locking gaskets are lengths of rubber that lock into place to provide a secure seal between stationary glass and a body panel. This “How to” article from Elasto Proxy explained how to install locking gaskets properly – and without risking breakage to windows or windshields. Readers also learned some tips and best practices that can save installers time while helping to avoid damage to body panels.

How Can We Help You in 2018?

Since 1989, Elasto Proxy has been provided sealing and insulation solutions that strengthen supply chains. We specialize in custom-fabricated seals, gaskets, and insulation in low-to-medium volume quantities for demanding applications.

How can we help you solve your sealing and insulation challenges in 2018? To get started, contact us.