Do you need a silicone hose connector for diesel-powered heavy equipment, an automotive application, or for electric vehicles (EVs)? If you’re an industrial company, Elasto Proxy can supply you with silicone hose connectors and all of the other rubber products that you need.

Elasto Proxy is manufacturing’s one-stop shop for custom seals and gaskets, thermal and acoustic insulation, molded rubber parts, and much more.

This article will guide you through silicone hose connector selection. Keep reading to start with some basics and then ask yourself some product-specific questions.

Start with the Basics

Do you know which type of silicone hose connector you need? That’s great if you do, but what are the temperature and pressure requirements? Do you need liners, reinforcements, rings, clamps, or EPDM inserts? And what about industry standards?

Which type of connector do you need?

- Elbows have strong, flexible bends.

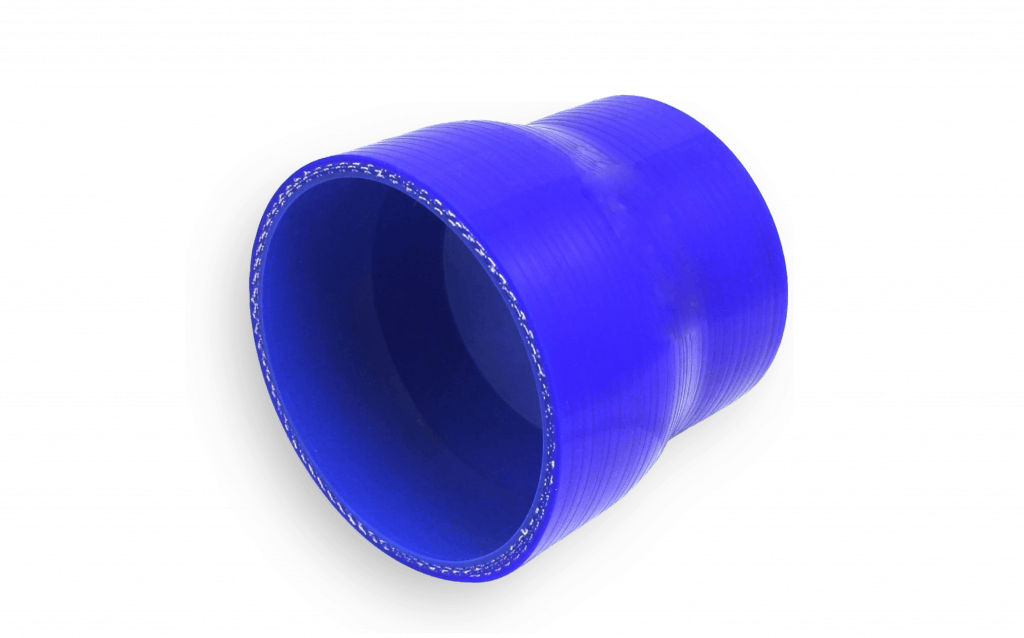

- Reducers are for different-sized pipes and tubes.

- Straight hoses come in coils or cut-to-size lengths.

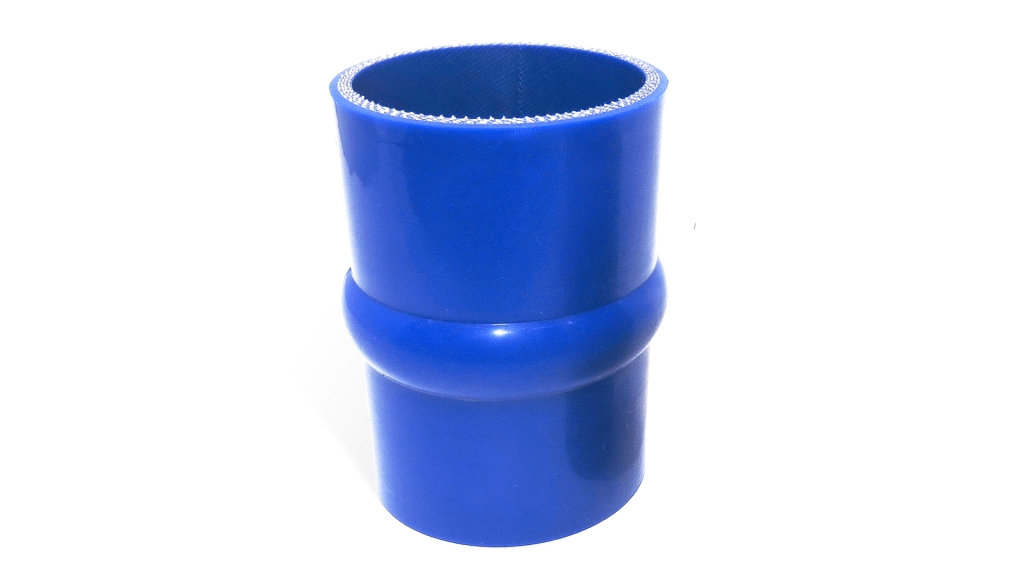

- Hump hoses are for slight intake adjustment.

- Wrapped hoses provide enhanced pressure resistance.

Important: Elasto Proxy also supplies custom silicone hose connectors for specialized applications.

What are your temperature and pressure requirements?

- Maximum temperature and minimum temperature define the temperature range.

- Working pressure is the highest amount of pressure during normal operation.

- Burst pressure is the maximum pressure before failure. Typically, it’s four times the working pressure.

Do you need products with liners, reinforcements, rings, clamps, or EPDM inserts?

- Fluorocarbon liners provide increased resistance to fuels and chemicals.

- Aramid* adds strength, increases high-temperature resistance, and resists abrasion.

- Polyester* promotes shape retention while adding strength and improving temperature resistance.

- Metal wire reinforcements protect against extreme pressure, including vacuum pressure.

- Stainless steel rings reduce swell and increase strength overall.

- Metal clamps promote assembly since you’ll already have the fasteners that you need.

- EPDM inserts cost less than silicone rubber and are used in low-temperature applications like cooling hoses.

*Aramid and polyester fabric reinforcements come in multiple ply (typically four) for greater durability.

Do you need a product that meets one of these industry standards?

- SAE J20 RI is for fuel hoses and heater hoses.

- SAE J20 R1 H.T. Class A is for radiator and coolant hoses.

- SAE J1726 is for charge air cooler (CAC) hoses.

- TMC RP303B Grade I and Grade II is for heater hoses and coolant hoses.

- U.S. military specifications include MIL-DTL-6000 for engine hoses.

- OEM-specific requirements come from original equipment manufacturers (OEM).

Ask Product-Specific Questions

Now that you’ve covered the basics, it’s time to ask some product-specific questions. If you need help, ask Elasto Proxy.

How do you select a silicone elbow?

- What’s the angle of the bend? Typically, it’s 45° or 90°.

- What is the total length of the elbow that you need?

- What are the sizes of each of the two sections, or legs?

- What’s the elbow’s inside diameter (ID)?

- What’s the elbow’s outside diameter (OD)?

- What’s the wall thickness?

- What are your temperature and pressure requirements?

- Do you need to meet an industry standard? If so, which?

- Do you need liners, reinforcements, rings, clamps, or EPDM inserts?

How do you select a silicone reducer?

- What’s the ID and OD of the reducer’s larger section?

- What’s the ID and OD of the reducer’s smaller section?

- What’s the total length of the product that you need?

- What’s the wall thickness?

- What are the temperature and pressure requirements?

- Do you need to meet an industry standard? If so, which standard?

- Do you need liners, reinforcements, rings, clamps, or EPDM inserts?

How do you select a straight silicone hose?

- What length of straight hose do you need?

- Do you need coils or cut lengths that come ready to install?

- What are the ID, OD, and wall thickness?

- What are the temperature and pressure requirements?

- Do you need to meet an industry standard? If so, which standard?

- Do you need fluorocarbon liners, fabric or metal wire reinforcements, rings, clamps, or EPDM inserts?

How do you select a silicone hump hose?

- What’s the thickness of the hump?

- What’s the length of the hose?

- What are the ID, OD, and wall thickness?

- What are the temperature and pressure requirements?

- Do you need to meet an industry standard? If so, which standard?

- Do you need fluorocarbon liners, fabric reinforcements, metal wire reinforcements, rings, clamps, or EPDM inserts?

How do you select a wrapped silicone hose?

- What length of wrapped hose do you need?

- Do you need coils or cut lengths?

- What are the ID, OD, and wall thickness?

- Do you need a wrapped hose with a fluorosilcone liner?

- Do you need a product with stainless steel rings to reduce swell and increase strength?

- What are the temperature and pressure requirements?

- Do you need to meet an industry standard? If so, which standard?

- Do you need fluorocarbon liners, fabric or metal wire reinforcements, rings, clamps, or EPDM inserts?

Where can you find the silicone hose connector that you need?

Elasto Proxy is your one-stop shop for silicone hose connectors and custom seals and gaskets, thermal and acoustic insulation, molded rubber parts, and more. If you’re ready to discuss your requirements or request a quote, contact us.