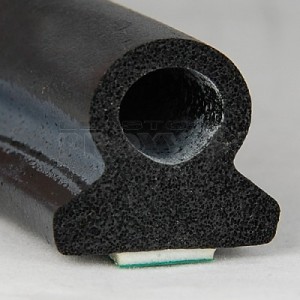

Closed Cell Sponge Rubber Gaskets

Closed cell sponge rubber gaskets from Elasto Proxy don’t just meet your application requirements for sealing and insulation. They meet your business requirements for a value-added solution.

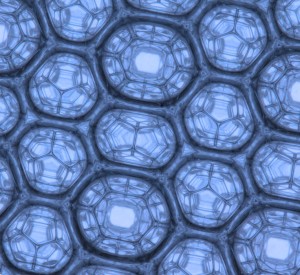

Closed cell sponge rubber gaskets prevent the flow of liquids and gases to and from the environment. They contain nitrogen-filled cells and provide reliable sealing, cushioning, gap filling, and insulation. Most sponge or expanded rubber is lightweight, flexible, and compressible. Over-compression can cause gasket failure, however, so compound selection is critical.

As an experienced gasket fabricator, Elasto Proxy helps you choose the right rubber for your application. We then custom-fabricate gaskets that save you time and money. Many types of closed cell sponge rubber are available, and different compounds provide particular properties. These sheet materials and rubber extrusions also support water jet cutting, adhesive bonding or splicing, and taping for peel-and-stick gaskets. (more…)

QPL connector gaskets meet demanding DoD standards. This is the second in a series of technical articles about why defense contractors choose EMI gaskets from Elasto Proxy.

QPL connector gaskets meet demanding DoD standards. This is the second in a series of technical articles about why defense contractors choose EMI gaskets from Elasto Proxy. In this case study, you’ll learn how Elasto Proxy helped a manufacturer of hospital beds to reduce costs, promote patient safety, and meet regulatory requirements. By applying the power of our supply chain strength, Elasto Proxy provides plastic parts that replace metal ones.

In this case study, you’ll learn how Elasto Proxy helped a manufacturer of hospital beds to reduce costs, promote patient safety, and meet regulatory requirements. By applying the power of our supply chain strength, Elasto Proxy provides plastic parts that replace metal ones.