Elasto Proxy Designs and Custom-Fabricates Dual Durometer Extrusions for Rubber Parts

Elasto Proxy Designs and Custom-Fabricates Dual Durometer Extrusions for Rubber Parts

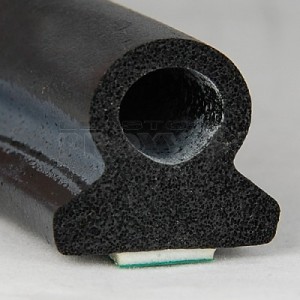

Dual durometer extrusions are industrial rubber parts with different areas of hardness. Typically, the harder rubber compound is used for attachment while the softer rubber is used for sealing. Sometimes, different rubbers are used because of design considerations such product color schemes or the use of pressure-sensitive adhesives (PSAs).

By fabricating dual durometer rubber into a single part, a product such as window seal can have areas with different physical properties to meet application requirements. With window channels, the harder window rubber attaches to the window frame and the softer window rubber faces the glass window. Durometer is not limited to window seals, however, and is used with both sponge and solid profiles.

Sponge Rubber, Solid Profiles, and Dual Durometer Rubber

Sponge rubber can be shaped into various industrial rubber products, including dual durometer profiles. By combining sponge rubber and solid rubber into a single part (such as bulb trim seals), different areas of hardness are achieved. Typically, sponge profiles are characterized as soft, medium, and firm. Choose open cell foam or closed cell foam, depending on your application requirements.

Solid profiles are harder than sponge profiles and, therefore, most resistant to compression. Most solid profiles range from under 30 duro to over 120 duro, depending on their shape. At 40 duro, solid rubber profiles have the consistency of pencil erasers. At 90 duro, they are hard like hockey pucks. Under low temperature conditions, solid profiles become harder.

How to Choose Dual Durometer Extrusions

Elasto Proxy offers a variety of dual durometer seals for a wide range of industrial and commercial applications. For example, standard bulb trim seals may have a 70 duro retainer and a medium foam bulb. More complex rubber profiles may require different colors or even plastics.

Tooling costs are higher for custom, complex parts; however, a wide range of standard, in-stock dual durometer profiles are available. When choosing standard dual durometer seals, consider product specifications such as materials, applications, seal dimensions, quantity per box, and quantity per coil. Elasto Proxy can also help with compound selection.

EPDM and TPE Dual Durometer Bulb Seals

Standard dual durometer bulb seals are often made of EPDM or TPE. A type of synthetic rubber, EPDM provides insulation against hot and cold temperatures. Applications include door seals and window seals for building and construction products, automotive applications, and mobile specialty vehicles. EPDM is also in green power projects.

Thermoplastic elastomers (TPE) are rubber-like materials that combine the processing strengths of thermoplastics with the best qualities of thermoset rubbers. Thermoplastics are temperature-sensitive plastics that become soft when heated, and then harden when cooled. Thermoset rubbers resume their normal shape after being stretched, twisted, or distorted.

How Can We Help You?

For over 20 years, Elasto Proxy has been helping partners strengthen their supply chains and solve difficult sealing challenges. How can we help you? For more information about Elasto Proxy’s dual durometer extrusions, please contact us or request a quote.