Trim seals from Elasto Proxy are used for sealing and insulation, typically on doors and hatches. Learn about compound selection and technical design for these industrial rubber products. Contact us with questions.

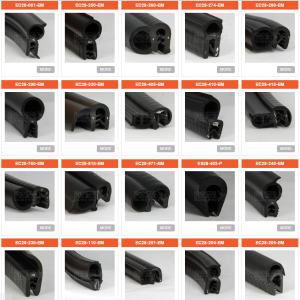

Bulb trim seals are sealing and insulation products with bulb and retainer sections. The bulb portion is often rounded or teardrop-shaped, but may resemble a half-moon or have a flat bottom. The retainer portion of the seal has a U-shape with an open end and two “legs”. The bulb provides sealing and insulation under compressive force, and the retainer or trim section presses onto the flange or substrate.

Each section of the seal (bulb and trim) are made of different materials. In turn, each material has a different durometer or hardness to support compression. For technical buyers and product designers, it’s important to choose the right materials and account for design factors such as bulb size, gap or edge thickness, and minimum bend radius. The following sections explain.

Bulb Materials

The bulb portion of a bulb trim seal is usually made of EPDM sponge rubber or a thermoplastic elastomer (TPE). EPDM provides excellent resistance to weather, ozone, aging, water, and steam. This durable synthetic rubber also remains flexible at low temperatures and is color stable. TPEs are also weather-resistant, but are reusable and typically recyclable.

Trim Materials

The retainer or trim portion of a bulb trim seal is usually made of PVC, a plastic that maintains its flexibility at lower temperatures and that resists kinking. PVC plastics also offer excellent impact resistance along with good abrasion resistance, tensile strength, and resilience. Like EPDM and TPEs, PVC is a good choice for outdoor applications.

Internal Supports and Exterior Finishes

The retainer section of the bulb trim seal can include an internal clip that’s made of aluminum or steel. This metal clip promotes permanent gripping under application conditions such as the opening and closing of doors. The retainer portion of the seal may also support the use of a hot-melt adhesive for fastening, and may have an outer coating made of vinyl to impart a textured finish.

Approvals and Certifications

During compound selection, technical buyers and product designers need to account for any regulatory requirements and industry approvals. Examples include:

- FVMSS 302 for interior automotive parts

- FAA/FAR 23.853 for aircraft interiors

- UL 50E for electrical equipment

- UL94HB for flame-resistant plastic parts

In addition to choosing the right compounds, buyers and designers need to consider key design factors.

Bulb Size

To determine the required bulb size for a bulb trim seal, measure the distance between the door and the jam when the door is closed. As a rule of thumb, add between 25% and 50% to this measurement to account for compression. Remember that over-compressing the bulb will not create a better seal. In fact, over-compression can reduce seal life and cause compression set, the permanent, unrecoverable deformation after a seal is compressed.

Gap or Edge Thickness

Buyers and designers also need to determine the gap or edge thickness for the retainer section of the bulb trim seal. This measurement is the distance between the two “legs” or straight sections of the retainer. As a rule, choose a bulb trim seal where the gap equals the substrate. In other words, choose a bulb trim seal with a gap of 1/2” for a substrate that’s 1/2”. Specifying a larger or smaller gap may result in leakage.

Minimum Bend Radius

The PVC that’s used in bulb trim seals can avoid kinking, but only if the angle isn’t too great (i.e., less than 90°). For product designs with a larger bend radius, recesses or valleys may form. These surface deformations can allow the passage of water. The results can range from leaky doors in automotive interiors to drafty exterior doors on buildings.

Color and Texture

Most industrial rubber products are black, but bulb trim seals are used in a variety of product designs. That’s why Elasto Proxy offers specialty sealing solutions that come in colors such as white, off-white, beige, tan, and gray. We can also source bulb trim seals with specific textures. Many industrial rubber products are flat and smooth, but bulb trim seals with coarse, pebbly, or ribbed finishes are available.

How Can We Help You?

Do you have questions about bulb trim seals? Please contact us for more information. Also, please note that Elasto Proxy will close for the winter holidays at noon on Thursday, December 24, 2015 and reopen on Monday, January 4, 2015. So please submit your remaining 2015 orders by December 1, especially if you’ll need sealing solutions with specialty materials.