Acoustic Foams for Noise Control in Vehicles and Equipment

Acoustical foams absorb and dampen sounds. Some of these foam rubber materials also provide flame resistance. Product designers need more than just an acoustic foam, however. They need a custom fabricator who can convert stock materials into a custom insulation solution.

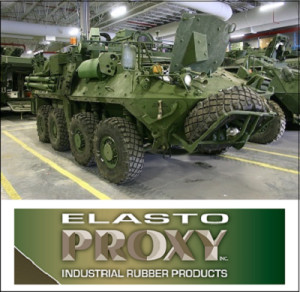

Acoustic foams are used for sound absorption and sound dampening in applications such as military vehicles, commercial trucking, and equipment enclosures. They’re usually made of silicone, urethane, or foam-based melamine. Some acoustical foams offer additional properties, such as thermal resistance or fire resistance. For specialized applications, acoustical foams can be added as layers within “insulation sandwiches” that also contain fillers, adhesives, and barrier materials. (more…)

Learn about military specifications for rubber gaskets, and why defense contractors need a custom fabricator that can do more than convert elastomeric materials.

Learn about military specifications for rubber gaskets, and why defense contractors need a custom fabricator that can do more than convert elastomeric materials.