Elasto Proxy’s Sound Blockers Guide explains how manufacturers can get sound-blocking acoustic insulation for industrial noise control. Standard and custom products are available.

Sound blockers are a type of acoustic insulation that blocks rather than dampens or absorbs sound, an invisible form of energy that travels through the air as a wave. Noise blockers, noise barriers, or sound barriers, as sound blockers are also known, are made of dense materials and placed between the source of the sound and its receiver. Applications for manufacturers include heavy equipment and machinery.

If you’re looking for sound blocking solution, keep reading to find answers to these questions.

- How do sound blockers work?

- How do you select sound blockers?

- What are some examples of sound blocking materials?

- How are sound blockers made?

- Where do you install a noise blocker?

- Does Elasto Proxy provide acoustic insulation samples?

Elasto Proxy fabricates sound blockers for the heavy equipment industry and can also help you to find noise control solutions for machine enclosures, such as with gensets. To request a quote, contact us.

How do sound blockers work?

A sound blocker diffracts the sound that is transmitted from a source to a receiver. Because sound is a wave, it bends (diffracts) when encountering an obstacle. When a sound barrier blocks the line-of-sight between the source and receiver, the Fresnel Number (N) can be calculated. This dimensionless number can be used to chart attenuation, the gradual loss of the sound’s intensity.

Sound blockers need to block any and all paths from the source to the receiver. Because sound travels the same path as air, even tiny gaps that admit air will also permit the passage of sound. Noise barriers are also affected by varying air speeds. An airflow that travels from the source to the receiver may diffract sound passing through the air and cause it to bend downward, allowing it to be heard.

How do you select sound blockers?

During acoustic insulation design, engineers need to ask and answer a series of questions. Each application is different, but this list is a good place to start.

- What is the source of the sound?

- How close to the source of the sound can you install the sound blocker?

- Do you need sound blocking plus sound absorption and/or vibration dampening?

- Is airflow a factor?

- What is the maximum insulation thickness that your application can support?

- Do you need resistance to media such as fuels, chemicals, or cleaners?

- Do you need resistance to a specific range of temperatures?

- Does your application require flame resistance?

- Do you need acoustic insulation that meets a specific standard, such as Class 1 fire rating?

- How will you install the installation?

What are some examples of sound blocking materials?

Sound blockers are usually made of vinyl, a dense but flexible material that also offers strength, durability, and resistance to moisture and humidity. Mass loaded vinyl (MLV), a type of vinyl, is often used because it contains salt, sand, or tiny metal particles for added mass with minimal thickness. This added mass helps to block the sound. MLV’s flexibility supports loading when an external force, such as pressing or bending, is applied. MLV’s relative thinness also supports effective acoustic insulation in tight spaces.

Mass loaded vinyl can be used as a standalone sound blocking material or in conjunction with sound absorbing or sound dampening materials. Although MLV provides good environmental resistance, it is important to remember that other types of acoustic insulation may have different material properties. Therefore, a sound barrier that’s suitable for a factory office may not be able to withstand the splash of automotive fluids in an engine bay, or the petroleum products used with machinery and equipment.

How are sound blockers made?

Sound blockers are supplied as sheets or rolls and converted to application-specific shapes and sizes with water jet cutting. The precision that water jet technology provides helps to prevent the creation of sound-permitting air gaps that can result when sound blocking materials with poor-quality cuts don’t conform with product features. Elasto Proxy has several water jet cutting machines for industrial rubber products.

Elasto Proxy can also combine materials together to create an acoustic insulation “sandwich” with the specific properties that you need. For example, we can laminate sound blockers to foams and facings that provide sound absorption and sound dampening. Melamine, a sound absorbing foam, is lightweight and flexible. Facings can provide frequency attenuation, chemical or abrasion resistance, decoration, or support for cleaning.

Sound blockers from Elasto Proxy can sandwich the barrier material between a decoupler and a layer of acoustic foam. Decoupling, the mechanical separation, of two sides of a structure, causes the sound barrier and the acoustic foam to vibration independently of each other for effective sound isolation. Elasto Proxy can also apply a pressure-sensitive adhesive (PSA) tape with a removable liner for installation.

Where do you install a noise blocker?

Ideally, noise blockers are installed as close as possible to the sound’s source, such as in an engine bay. The next best location is near the receiver, such as the driver in a mobile equipment cabin. You can also install our sound blocking products on walls, ceilings, or floors; around pipes or HVAC ducts; or within machine enclosures, mechanical rooms, or mobile equipment.

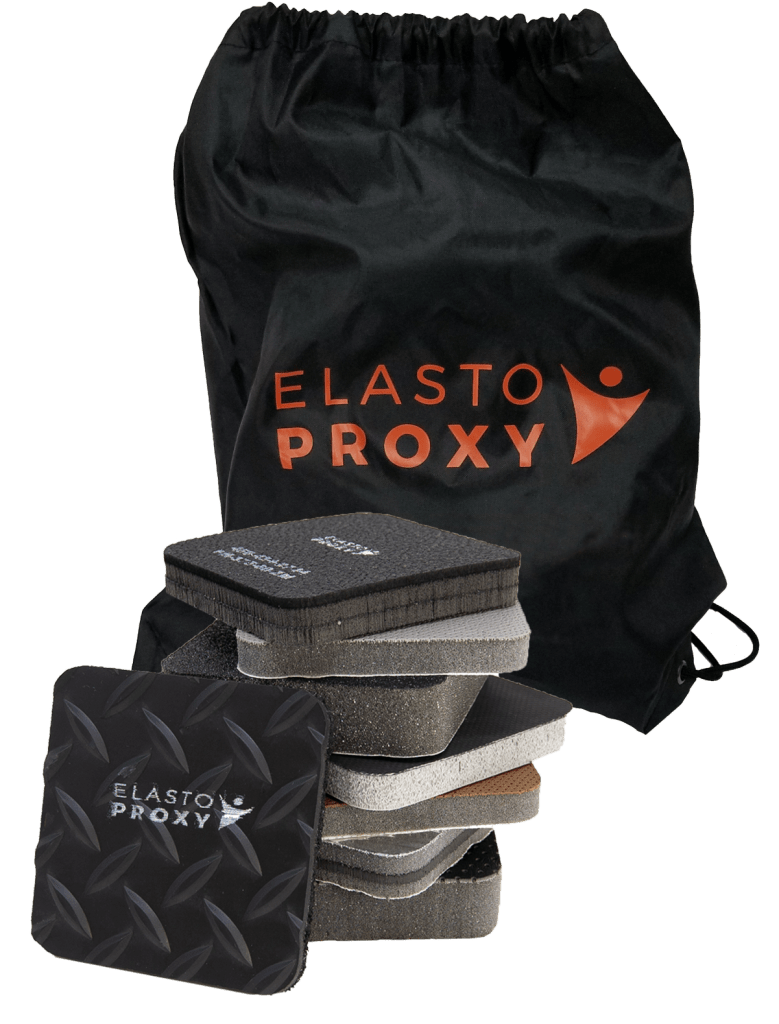

Does Elasto Proxy provide acoustic insulation samples?

Yes. For acoustic insulation samples that you can see for yourself and hold in your hands, ask for the Elasto Bag. This sackful of samples from Elasto Proxy includes FM-500-60-ZM flooring, a single layer of acoustical foam that’s bonded to a sound barrier. The top of insulation sandwich features a durable, wear resistance, diamond plate design. Applications for FM-500-60-ZM include floormats and flooring in both on-road and off-road equipment. It’s also a good choice for runner and anti-fatigue mats.