Elasto Proxy fabricates many different types of silicone gaskets. Let us know what you need.

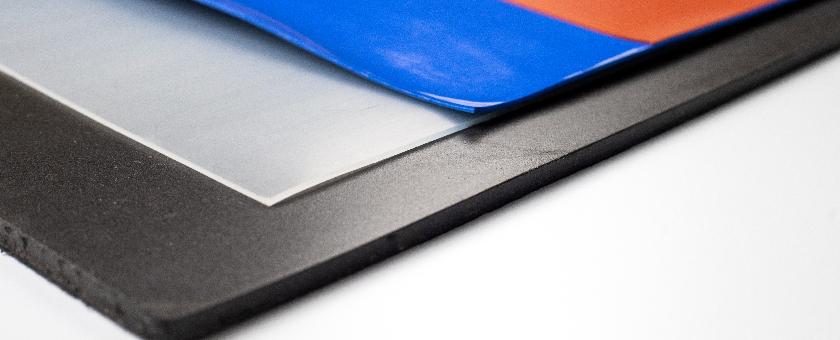

Silicone gaskets are fabricated from sheets, rolls, extrusions, or ready-to-mold compounds. Silicones, a family of synthetic elastomers, provide excellent environmental and temperature resistance. They also have low toxicity and are electrically insulating.

Depending on what’s added to a silicone compound, however, a silicone gasket can be electrically conductive instead. It can also conduct heat instead of insulating against it, or impart specialized properties such as EMI shielding, biocompatibility, or flame resistance.

Elasto Proxy stocks standard silicone elastomers and can custom-order compounds to meet your application-specific requirements. Typically, we water jet cut silicone gasketing from sheets or rolls of solid, sponge, or foam rubber. We can also supply you with molded silicone products if you need them.

Types of Silicone Gaskets

There are many different types of silicone gaskets, and there are plenty of ways to categorize them. For example, Elasto Proxy can supply you with:

- Solid silicone gaskets

- Silicone sponge gaskets

- Silicone foam gaskets

- Electrically conductive EMI shielding gaskets

- Thermally conductive silicone gaskets

- Medical grade silicone gaskets

- Flame-resistant silicone gaskets

- Silicone gasketing that meets other requirements

This article describes each type, and we invite manufacturers to contact us for a quote.

Solid Silicone

Solid silicone gasketing is made of silicone elastomers that have a tightly-packed molecular structure. Elasto Proxy fabricates these sealing solutions from silicone sheets, rolls, or extrusions in a range of durometers, a measure of hardness. Lower-durometer silicones are soft and compressible. Higher-durometer silicones are harder and provide impact resistance instead of cushioning.

Silicone Sponge

Silicone sponge gaskets are made of silicones with a cellular molecular structure. These gasketing materials contain tiny cells, or pockets, that are either open or closed. Open cells allow air, chemicals, and water to pass through unless the gasket is compressed, typically to seal out air or light. Closed cells prevent the passage of these substances at low pressures, which makes them a good choice for sealing out water.

Silicone Foam

Like silicone sponge, silicone foam has either open cells or closed cells. However, silicone foams tend to have a smoother “skin” or surface because of how they are cured. Also, whereas a silicone sponge is usually soft and compressible, silicone foam is usually rigid. During material selection then, it’s important to work with a gasket fabricator who understands these differences.

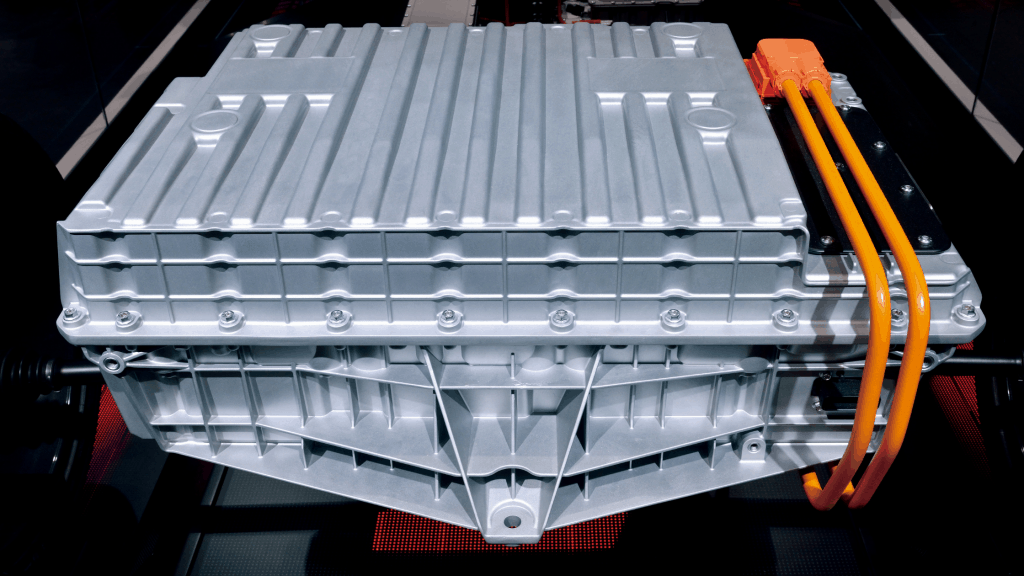

Electrically Conductive EMI Shielding Gaskets

Electrically conductive EMI shielding gaskets are made of silicone compounds that are filled with metal or metal-coated particles. Unlike the silicone base, the particles are electrically conductive and provide shielding against electromagnetic interference (EMI), a form of electronic noise that can interfere with circuits. EMI O-rings, a type of gasket, can also be made from EMI silicones.

Elasto Proxy can supply you with EMI silicone gasketing made with the following fill materials:

- Nickel-aluminum

- Nickel-graphite

- Silver-aluminum

- Silver-copper

- Silver- glass

- Silver-nickel

Many of these silicone compounds meet the requirements of MIL-DTL-83285, a U.S. military standard for EMI shielding. They are also less expensive than pure silver-filled materials.

Thermally Conductive Silicone Gaskets

Normally, silicone insulates against heat; however, when aluminum oxide or boron nitride is added, the resulting compound becomes thermally conductive instead of thermally insulating. Typically, thermally-insulating silicones are used with electronics to move heat away from sensitive components. With water jet cut thermal pads, the sheeting may contain a fabric reinforcement for added strength.

Medical Grade Silicone Gaskets

Medical grade silicones can be made of sponge, solid, or foam materials and meet FDA or USP Class VI requirements. For example, Elasto Proxy can source FDA-approved silicone sponge for medical equipment gaskets. We can also fabricate silicone seals from USP Class VI materials that meet biocompatibility testing requirements from the U.S. Pharmacopeia (USP).

Flame Resistant Silicone Gaskets

Flame-resistant silicones can also be made of sponge, solid, or foam materials, but in compounds that meet UL 94 flammability requirements or that meet flame, smoke, and toxicity (FST) requirements for the transportation industry. This category of silicone solutions also includes products that combine flame resistance with EMI shielding. Typically, this type of gasketing is used by the aerospace industry.

Silicone Gasketing That Meets Other Requirements

Elasto Proxy can also supply you with silicone enclosure gaskets that meet requirements for ingress protection (IP), or that meet ratings from the National Electrical Manufacturers Association (NEMA). If you’re not sure if we can provide what you need, just ask. With our strong supplier network and robust manufacturing capabilities, we can probably provide the silicone gasketing that you need. Ready to learn more?