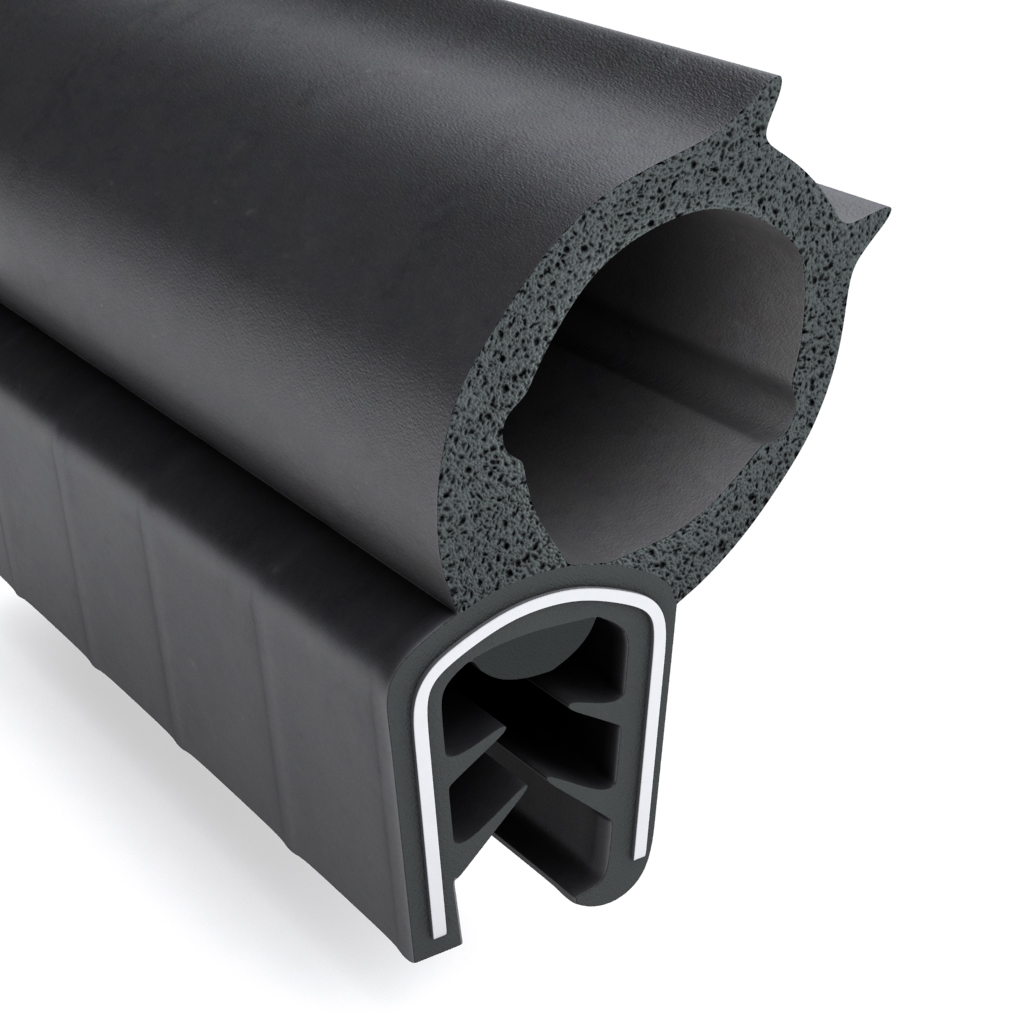

Rubber trim seals provide sealing and insulation for doors or hatches with rounded corners. These dual durometer rubber products are co-extruded and consist of a softer bulb that compresses to fill a gap and a harder trim section that attaches to an edge or flange. When the door or hatch is closed, the bulb compresses. Then, when the door or hatch is opened, the bulb returns to its original size and shape. The bulb and trim each have a different hardness, or durometer, because of their different functions.

Like most industrial rubber products, rubber trim seals usually come in black; however extrusions in other colors are also available. The finish of a rubber trim seal is usually smooth, but you can choose products with a textured finish instead. Typically, however, the most important considerations during product selection involve specific features of the bulb and trim. Keep reading to learn about these trim seal specifications, or request a quote from Elasto Proxy.

Bulb Specifications for Rubber Trim Seals

The bulb section of a rubber trim seal has four key specifications.

- Material

- Durometer

- Shape and Location

- Measurements

Bulb Material

The bulb section is usually made of EPDM, TPE, PVC, or silicone. The bulb can be made of the same material as the trim, or it can be made of a different material. Each of the materials you can select have specific advantages in terms of their properties.

- EPDM remains flexible at lower temperatures and resists water, weather, sunlight, and ozone

- TPE is also weather-resistant, but it’s recyclable and supports custom colors.

- PVC is strong and smooth but also flexible and lightweight.

- Silicone provides low toxicity and thermal stability over a wide temperature range.

No matter which material you choose, the bulb is made of sponge rubber instead of solid rubber. Sponge rubber has a cellular structure and can either hold back fluids or permit their passage. Sponge rubber usually provides greater cushioning than solid rubber but durometer is the true measure of hardness.

Bulb Durometer

The durometer of the rubber bulb is expressed on the Shore A scale. Typically, a medium-durometer rubber (50 to 70 Shore A) is used. Otherwise, if the bulb is too soft, it won’t “bounce back” after an applied force (such as a door or hatch) is removed. This failure to bounce back is called compression set, and it’s a leading cause of seal failure. Yet, if a bulb is too hard, the door or hatch won’t close easily or properly.

Bulb Shape and Location

Most rubber trim seals use a rounded bulb; however, some products have bulbs that are teardrop-shaped, look like a half-moon, or use other shapes instead. Sometimes, bulbs have an extended lip or lips as well. For any type of bulb, the bulb location can also vary. Depending on how the door or hatch opens, you may need a rubber trim seal with a top bulb (vertical trim seal), a side bulb, or a bulb that’s at an angle.

Bulb Measurements

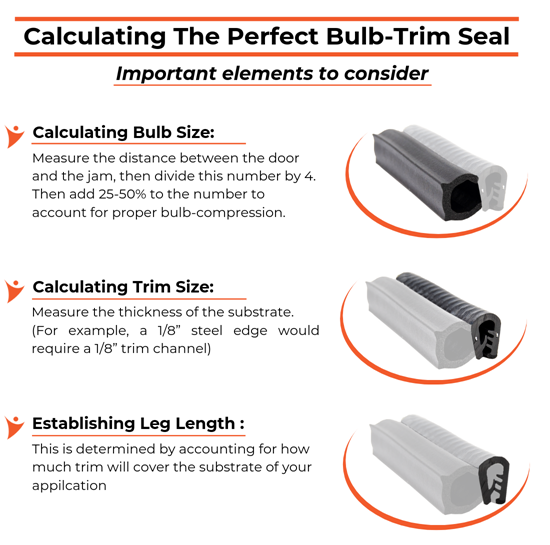

Bulb size is a key measurement that’s represented by this calculation.

Average Jam Dimension + Compression Percentage = Bulb Size

Determining the bulb size you need is a multi-step process. First, calculate the average jam dimension for the door or hatch. Start by placing some modeling clay in each corner and then close the door or hatch to compress the clay. Then insert calipers into the clay and record this dimension, or gap size, for each corner. Now divide this number by four to get the Average Jam Dimension.

Next, apply a compression percentage of 25% to 50% to the average jam dimension. Don’t apply more than 50% because over-compression can reduce seal life and cause compression set.

If you’re ready to order bulb trim seals and need some assistance, contact Elasto Proxy.

Trim Specifications for Rubber Trim Seals

The trim section of the rubber seal has three key specifications.

- Material and Durometer

- Gripping and Impact Resistance

- Measurements

Trim Material and Durometer

Like the bulb, the trim can be made of EPDM, TPE, PVC, or silicone. Moreover, the trim can use the same type of material as the bulb, or it can use a different material depending on your application requirements. No matter which trim material you select, the trim uses solid rubber instead of sponge rubber. The trim also has a higher durometer, or greater hardness, than the bulb section.

Gripping and Impact Resistance

The trim, or retainer, is designed to grip an edge or flange and provide reliable attachment. The trim also provides greater impact resistance than the soft, compressible bulb. For added gripping, the trim can have one or more interior tongues and in different locations. For added impact resistance, the trim can contain steel wire or segmented steel cores.

Trim Measurements

Trim thickness is an important measurement during rubber trim seal selection. This thickness, or gap, is the distance between the two straight sections (legs) of the trim. As a rule, trim thickness should equal flange thickness. For example, if a trim seal has a flange that’s 1/2” thick, choose a trim thickness of 1/2”. Choosing a trim seal with a larger or smaller thickness than this may result in leakage.

There’s another key trim measurement as well: bend radius. Although trim seals are designed for radiused corners instead of 90° ones, you still need a bend radius that will support flexing or bending and avoid kinking. To determine the bend radius, find the minimum distance from the center point to the edge (i.e., the radius) that the rubber gasket must bend.

Remember that although a more flexible material can support a smaller bend radius, a radius that’s too tight can cause the corners of the trim seal to pop out. By the same token, a bend radius that is too large can cause the formation of recesses or valleys that allow the passage of water.

How to Order Rubber Trim Seals from Elasto Proxy

Elasto Proxy is a rubber fabricator and distributor that supplies manufacturers with coils, cut lengths, and finished gaskets. We keep bulb trim seals in stock and can ship them to you from our strategically located warehouses in North America and Europe. Fabricating your own gaskets in-house might seem cost-effective but find out how we can save you time and money with our ready-to-install solutions.