Learn why data centers need UL 94 HB EPDM flame retardant gaskets – and how to select them.

Data center fires are rare but potentially catastrophic. For example, when fire destroyed the OVHcloud facility in Strasbourg, France in March 2021, the cost of damages exceeded $30M. Although the cloud computing company established a compensation fund, its customers filed a $10M class action lawsuit for the loss of business-critical services.

UL 94 HB EPDM rubber won’t prevent data center fires from happening, but gaskets that are made from this flame retardant elastomer can help mitigate fire damage. That’s because these industrial rubber products are made of a specialty compound that meets UL 94 HB, a flame rating from Underwriters Laboratories (UL) that is part of the larger UL 94 standard.

Typically, UL 94 HB EPDM gaskets are used with doors or panels. If you’re a data center construction company, Elasto Proxy can supply you with UL 94 HB EPDM sponge rubber in coils, cut lengths, or ready-to-install products. Contact us to request a quote or keep reading to learn more about these flame retardant gaskets for data centers.

What is UL 94 HB?

Maybe you’ve heard of UL 94 V0 for electronic enclosures, but that flame rating is for vertical burning. UL 94 defines a horizontal burn (HB) for a test specimen instead and is used with applications like data center panels. Prior to UL 94 HB testing, a specimen is kept at 23°C (73.4°F) for 48 hours. The material is then subjected to a horizontal burner flame for a total of 30 seconds.

The table below describes the test criteria.

Test specimen thickness 3 to 13 mm | ≤ 40 mm/min |

Test specimen thickness < 3 mm | ≤ 75 mm/min |

Flame is extinguished before first mark | = 0 mm/min |

Where is the proof that Elasto Proxy’s material meets UL 94 HB?

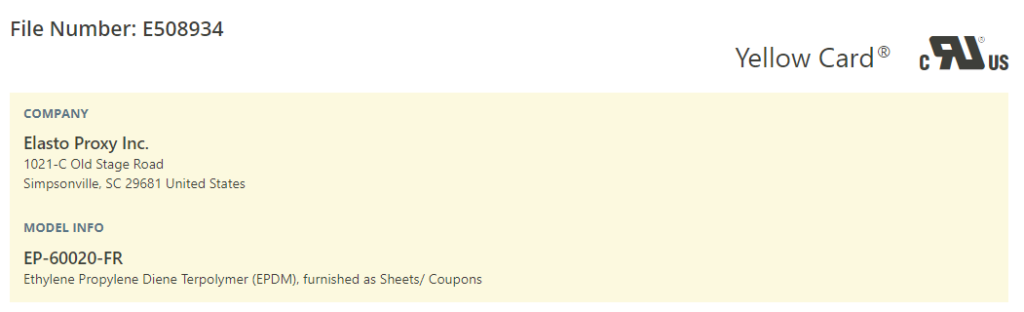

The material that Elasto Proxy uses for UL 94 HB gaskets is UL Listed and has a UL Product iQ number.

The screen shot below is from the on-line version of the UL Yellow Card.

What are this material’s properties?

As listed on the UL Yellow Card, Elasto Proxy’s UL 94 HB EPDM rubber (EP-60020-FR) has the following flammability, ISO/IEC flammability, and thermal properties. The values below are for a 5.7 mm sample that is black in color.

Properties | Value | Test Method |

Flammability Properties |

|

|

Flammability | HB | ANSI/UL 94 |

ISO/IEC Flammability Properties | IEC 60695-11-10 | |

Flammability | HB40 | |

Thermal Properties | ||

Relative Thermal Index – Electrical Strength | 50° C (122° F) | UL 746B |

Relative Thermal Index – Mechanical Impact | 50° C (122° F) | UL 746B |

Relative Thermal Index – Mechanical Strength | 50° C (122° F) | UL 746B |

Why use EDPM sponge rubber for data center gaskets?

Most data-center fire suppression systems are water-based, so gaskets need to resist water in both its liquid and gaseous forms. EPDM rubber provides strong environmental resistance and can also resist the 212°F (100°C) heat that turns water into steam. The medium-durometer EPDM sponge rubber that Elasto Proxy uses also supports proper compression for reliable sealing.

What other features can these data center gaskets have?

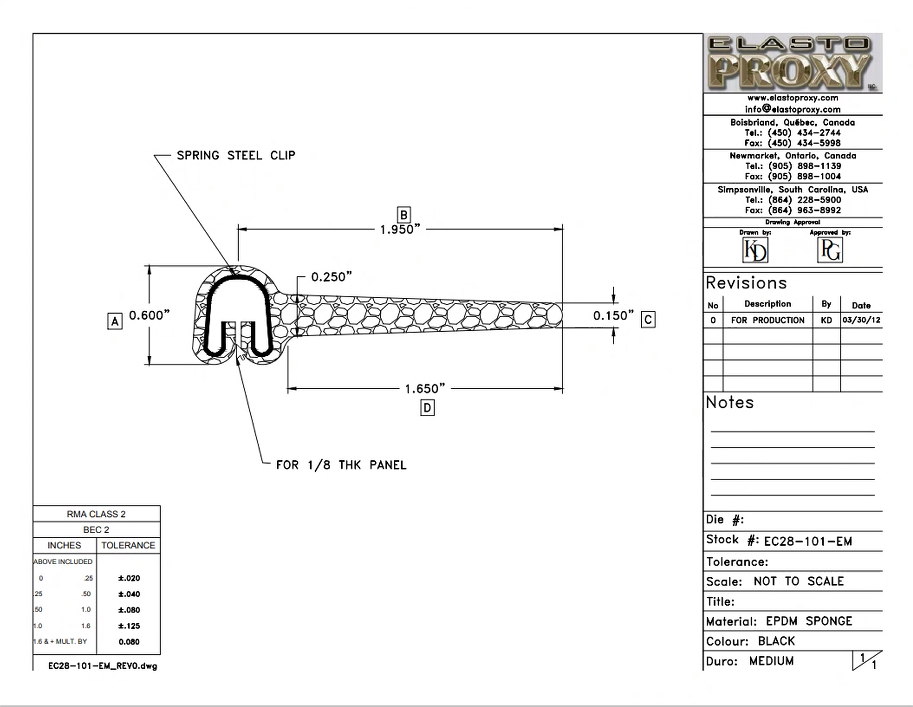

Data center gaskets need to be soft enough to compress, fill the gap between panels, and form a seal. Yet the rubber must also be strong enough to withstand compressive forces that can crush a gasket and cause seal failure. The compound that Elasto Proxy sources can include a spring steel clip for impact resistance.

This steel clip is part of EC28-101-EM, our standard product for 1/8” (3.175mm) thick data center panels.

What are some differences between standard and custom data center gaskets?

Elasto Proxy keeps EC28-101-EM in stock and offers this gasket material in economic order quantities of 2,500 feet. Minimum order quantities (MOQs) can be less, however. Because the tool, or die, for this extrusion already exists, lead times are as short as two weeks. For custom extrusions, it can take up to eight weeks to make a die and a sample. For new extrusions, MOQs of 1,000 feet apply.

What is the color of the standard gasket material?

The compound that Elasto Proxy uses for UL 94 HB EPDM gaskets is black in color. Data center builders and operators can request a different color, such as white, instead; however, this will require testing to ensure that the material meets the requirements of UL 94 HB.

How do you install UL 94 HB EPDM gaskets in data centers?

Elasto Proxy can supply you with UL 94 HB EPDM gaskets that come with flame-resistant adhesive tape. Installers can then remove the tape’s protective backing and stick the gasket to data center surfaces. Like the UL 94 HB EPDM gasket material itself, this tape is UL approved. Elasto Proxy can also tape custom extrusions that come in different sizes and shapes, and that are designed to fill larger or smaller gaps.

How can you order EC28-101 for flame retardant data center gaskets?

Elasto Proxy is ready to supply you with this medium-durometer, EPDM sponge rubber product.