Learn how to select and install locking gaskets from Elasto Proxy. We supply sealing solutions to manufacturers.

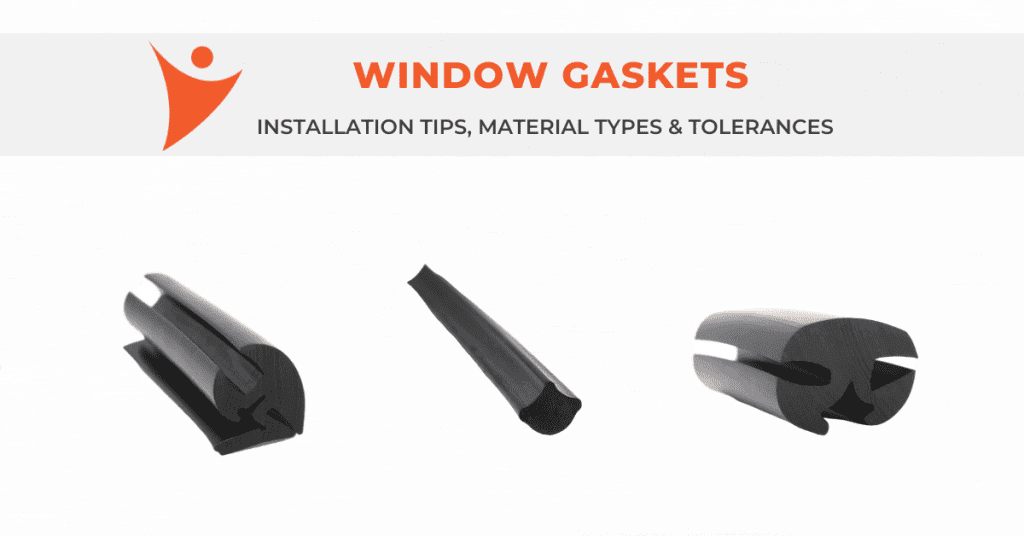

Locking gaskets are rubber extrusions that lock into place to provide a secure seal between stationary glass and a body panel. There are two types: self-locking and keyed. Both are used with the windows and windshields on heavy equipment, and with the viewing windows on machine and equipment enclosures.

Locking gaskets are important to your design because they hold window glass in place. Gaskets that are too small won’t fit over the glass, and forcing them into place can cause windows or windshields to break. Gaskets that are too large may leak and won’t provide you with a reliable sealing solution.

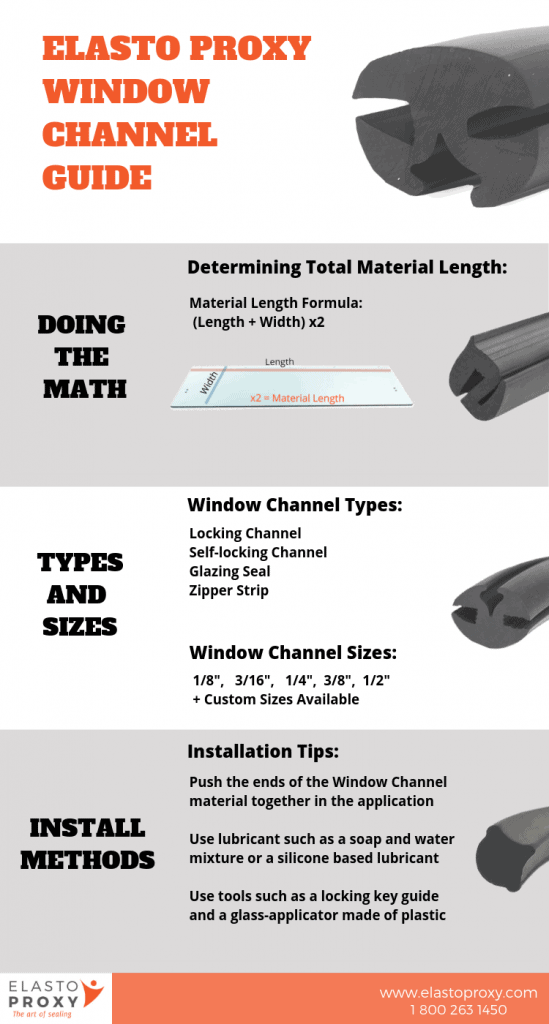

In this guide from Elasto Proxy, you’ll learn how to select locking gaskets based on dimensions, tolerances, and materials. You’ll also learn some best practices for installing window gaskets or window channels, as these rubber products are sometimes called.

How do you size a window gasket?

Starts with a few basic measurements. First, measure the thickness of the glass that the gasket needs to cover. Next, measure the glass’ height and width. Add these numbers together and then multiply the sum by two. This gives you the overall length of the extrusion that you’ll need.

What about rubber tolerances?

Some engineers are more familiar with metal parts than with rubber profiles. That’s why it’s important to understand that rubber can shrink and stretch significantly. Tight tolerances are possible with metal channels, but not with the rubber extrusions used in window gaskets. When you define your design, remember to specify rubber part tolerances that are achievable.

Important: Remember that rubber can shrink when it’s cold. So, it’s a good idea to add a bit of extra length (but not too much) to prevent the edges of the gasket from separating.

How do you select the right locking gasket material?

With construction and forestry equipment, EPDM is a good choice because this rubber remains flexible at low temperatures and resists moisture and sunlight. With machine and equipment enclosures, compounds like nitrile or neoprene that resist contact with oils may be required. With food processing and medical equipment, you may need an FDA-approved silicone rubber instead.

Do you have to cut the extrusion yourself?

Locking gaskets come in lengths of rubber that you can cut yourself. However, you can also buy locking gaskets that are cut-to-size and come ready-to-install. Cutting your own window rubber might seem cost-effective, but mis-cuts create material waste. There’s also an opportunity cost since employees who are cutting rubber can’t perform other activities.

What do you need to do before installing the glass?

Before installing the glass, lubricate the locking gasket with a mixture of soap and water or a silicone-based spray. To prevent the lubricant from wetting other surfaces, hold the spray bottle or can in one hand and a piece of cardboard in the other. Position the cardboard on the other side of the window or windshield area that you plan to spray.

What do you do when it’s time to install the glass?

Start with the body side first. In other words, don’t start inside the cabin or enclosure. Rest the bottom of the glass in the gasket so that you don’t have to struggle with the weight of the window or windshield. A knife-like tool with a plastic blade can help to prevent glass breakage as you work the gasket’s lip over and around the glass. When the lip is fully over the glass, the glass will pop into place.

How do you get the window gasket to lock?

Some installers use a screwdriver, but the blade can slip and scratch the body panel. Gasket tools with a screwdriver-like handle and hooked end are a better choice. Some have pointed tip or metal ball at the end. The latter type is effective because the ball tends to stay in place and won’t rip the gasket. Plus, if the tool comes loose, the ball is less likely to scratch the body panel.

What about the body panel?

When you press a locking gasket onto a body panel, remember to push the gasket’s ends together so that there’s more material in the loop that forms. Pressing this loop downward forces material into the application and prevents stretching. If there’s residual lubricant on the window or windshield, wipe the surface clean with a rag.

What’s the best way for manufacturers to buy locking gaskets (including 1/8”)?

Elasto Proxy keeps hundreds of rubber profiles in stock and can custom-fabricate the locking gaskets that you need. Whether you need window rubber with a 1/8” edge or in some other size, we’re ready to help.