Lightweighting for electric buses is a design strategy for reducing vehicle weight while maintaining or improving strength, stability, and performance. Electric vehicles (EVs) are heavier than their internal combustion engine (ICE) counterparts, and buses are no exception.

Elasto Proxy supplies lightweight parts to electric bus manufacturers. Examples include:

- Battery gaskets

- Door and window seals

- Acoustic insulation

- Molded rubber and plastic parts

Keep reading to learn more and contact us for a quote if you’re a manufacturer.

Buses, Batteries, and the Bottom Line

In any type of EV, the battery is the heaviest and most expensive component. Reducing a battery’s weight enables an electric bus to travel farther on a single charge. It also means less energy is needed to get a bus up to speed.

That’s important for performance, but there are financial considerations as well. They affect the transit authorities or transportation agencies who buy electric buses, as well as the manufacturers who make these battery-powered vehicles.

Transportation Agencies

For transportation agencies, an electric bus that’s out of service for charging is an asset that’s not generating revenue. There’s also a cost to the charge itself. Waiting to recharge a bus until the end of a driver’s shift might not be possible, and finding a convenient charging station may be impractical.

Electric Bus Manufacturers

Reducing the weight of the battery will have the largest impact on EV lightweighting. Advances in battery technology are helping, but e-bus manufacturers who find other ways to offset battery weight can capture greater share of a market that’s expected to reach $50.14B (USD) by 2030.

For electric bus manufacturers who partner with Elasto Proxy, the benefits include quality products backed by a level of service you won’t find anywhere else.

Battery Gaskets

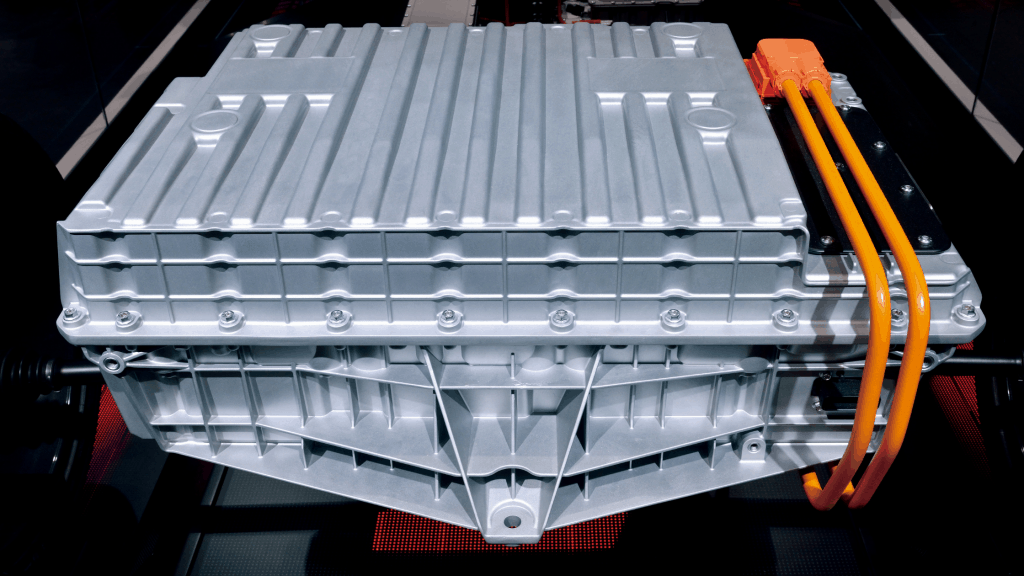

Like other types of EVs, electric buses need sealing and insulation solutions for the enclosures that hold electric batteries. These box-like structures have a large sealing area and contain multiple compartments for battery cell modules.

Battery Cover Gaskets

Most battery enclosures are made of aluminum, a lightweight metal, and are subject to high temperatures, harsh chemicals, and physical stresses. Elasto Proxy can fabricate battery cover gaskets from lightweight silicone and polyurethane foams that withstand these conditions.

Battery Compartment Gaskets

Environmental sealing and insulation is also needed inside each battery compartment. Closed-cell silicone sponge is a good choice because it can handle the heat produced by battery modules. It also dampens vibrations. Elasto Proxy fabricates gaskets made of this lightweight material.

Door and Window Seals

Traditionally, the door and window seals for buses have been made of EPDM rubber. EPDM provides excellent environmental sealing, but it’s not recyclable. It’s not the lightest-weight elastomer an electric bus manufacturer can choose either.

Thermoplastic elastomers (TPE) weigh less than EPDM and provide other advantages despite their higher cost. For example, TPEs are recyclable and support color matching. Elasto Proxy fabricates TPE seals and can leverage our procurement and warehousing capabilities to help you control costs.

Acoustic Insulation

Electric buses are quieter than their diesel-powered counterparts. That helps reduce noise levels along bus routes, but riders may hear more road noise. The headliners, side panels, and floor mats that Elasto Proxy makes can reduce noise vibration and harshness (NVH) within bus interiors.

With all these products, Elasto Proxy can laminate acoustical foams to other materials for sound blocking, dampening, or absorption. We can also apply adhesive tapes to your parts for ease-of-insulation. With our water jet cutting equipment, there’s no tooling to wait for or pay for either.

Molded Plastic and Rubber Parts

In addition to battery gaskets, door and window seals, and acoustic insulation, Elasto Proxy can also supply electric bus manufacturers with these and other molded rubber and plastic parts:

- Silicone connectors

- Rubber grommets

- Vibration mounts

- Rubber bumpers

- Rubber hose clamps

Are you ready to learn more? If you’re an electric bus manufacturer, we invite you to contact us.