Continuous improvements can increase manufacturing efficiency, reduce waste, and promote employee engagement. They’re not about changing one part of your business or asking managers to change everything at the same time. Rather, continuous improvements extend across the enterprise and involve everyone in making incremental changes to the processes they affect – and that affect them.

Continuous Improvements are Organization-Wide

From the C-Suite to the assembly line, and across purchasing, operations, and engineering, a true commitment to continuous improvement is both organization-wide and never-ending. But where should a manufacturer begin? Because every company is different, there isn’t a right or wrong answer. That’s why this article presents options and includes some examples that may apply to your situation.

Improve How You Buy, Specify, and Install Rubber Products

Keep reading to learn more, and ask Elasto Proxy how we can help you make continuous improvements to the way you buy, specify, and install industrial rubber products. Our solutions providers are ready to support you in making continuous improvements through vendor consolidation, kiting and custom packaging, and reducing manufacturing waste.

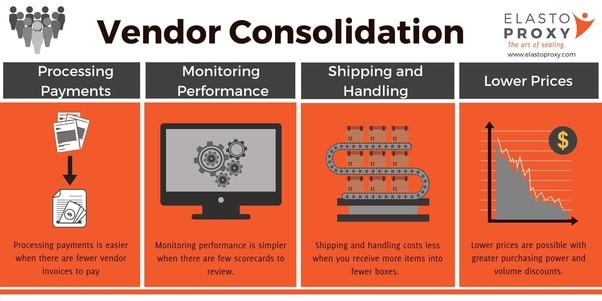

Vendor Consolidation

Vendor consolidation is about reducing the number of vendors you buy from. There’s a cost to carrying a vendor, and that cost could outweigh the benefits if you’re buying a single part in low or occasional volumes. For example, if you’re buying gaskets from Vendor A, grommets from Vendor B, and vibration mounts from Vendor C, you could realize the following benefits by buying all three parts from one vendor.

- Lower prices

- Fewer payments and better terms

- Easier vendor monitoring

- Less expensive shipping

- Faster handling

- More efficient stocking

Kitting and Custom Packaging

Manufacturers that have too many SKUs spend an excessive amount of time finding, sorting, handling, and organizing parts. This adds labor costs, requires more storage space, ties up cash in inventory, and increases tax liabilities. Kitting reduces SKUs by grouping two or more related parts into a new SKU that’s ordered, received, installed, and paid for together.

Kitting can simply put related parts into the same box, but manufacturers can also buy kits where parts are packaged in order of assembly. For example, a cabin manufacturer can kit a headliner and flooring together. If the headliner is installed first, the kit can put that part on top. For a seat assembly, however, all the molded parts for a build could simply arrive in the same box.

In both these examples, the benefits of kitting and custom packaging include:

- Faster assembly

- Reduced overhead

- Volume discounts

- Reduced packaging waste

- Fewer errors

Reducing Manufacturing Waste

Manufacturing waste is any expense or effort that does not transform materials into a product for which a customer is wiling to pay. It takes eight forms, all of which cost manufacturers time and money.

- Transportation

- Inventory

- Motion

- Waiting

- Over-Production

- Over-Processing

- Defects

- Unused Knowledge

Consider all the forms of waste in this hypothetical example of a mobile equipment manufacturer.

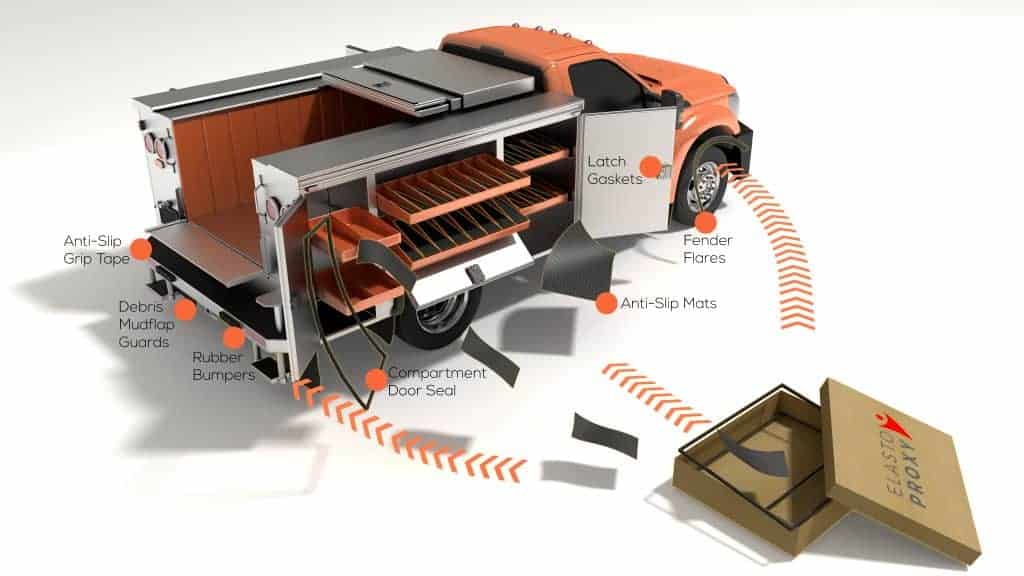

Mobile Equipment Example

Purchasing orders each part separately and from a different vendor. Receiving inspects and unpacks a different box for each part, and all these SKUs require separate storage locations. Inventory personnel pick one part at a time and wander between rows of shelves to hunt for individual SKUs. Meanwhile, installers wait for parts on the assembly line.

The first part to arrive is a coil of rubber for door gaskets. Well-paid welders spend their time cutting rubber instead of joining metal. The handheld knives they use are imprecise, and mis-cuts are thrown away. Neither Purchasing nor Engineering know how much material is discarded, or that the welders are increasing work-in-process (WIP) costs by cutting rubber for next month’s assemblies.

These metal workers are highly skilled, but it takes them longer to fabricate and install a gasket than to install a pre-fabricated product. The engineers who specify the door rubber aren’t aware it could come with an adhesive tape, and the line managers don’t ask the welders about gasket installation. Meanwhile, C-Suite personnel say things are too busy to even think about commissioning a time-and-motion study.

Ask Elasto Proxy about Continuous Improvements in Manufacturing

Does any part of the previous example sound familiar? Could you save time and money through vendor consolidation, kitting and custom packaging, or by targeting specific forms of manufacturing waste? When it’s time to improve the way you specify, buy, and install industrial rubber products, talk to Elasto Proxy. We’re ready to put our experience to work for you.