Floor matting is used in the products that manufacturers make and beneath the feet of the workers who make them. For example, heavy equipment manufacturers install rubber floor matting in operator cabins to provide a long-wearing, anti-slip surface. These manufacturers may also need anti-fatigue mats for assembly line workers who stand for long periods of time on hard surfaces like cement floors.

Applications for floor matting aren’t limited to the heavy equipment industry, however. For example, commercial kitchen floor mats provide an anti-slip surface with drainage holes so that liquids and debris can pass through. Wet area floor mats are also used in food manufacturing facilities where equipment requires frequent washdowns, and in hospitals, laboratories, gyms, and locker rooms.

Elasto Proxy supplies commercial and industrial customers with rubber floor matting that’s cut-to-size and arrives ready to install. Because we’re both a fabricator and distributor, we can also provide you with sheets or rolls of rubber flooring. Buying pre-fabricated products from us can save you time and money, however, and Elasto Proxy can laminate flooring and floor mats to acoustic insulation.

Keep reading to learn more, or contact us to discuss your application.

Floor Matting Materials: Types, Colors, Finishes, and Features

Floor matting for commercial and industrial applications is usually made of nitrile, styrene-butadiene (SBR), polyurethane (PU), polyvinyl chloride (PVC), silicone, or other types of rubber. Material selection depends on your specific application, so ask Elasto Proxy which flooring material has the properties and price point that you need.

For example, commercial kitchens might need custom rubber floor mats that are made of elastomers with additives that resist microbial growth. Industrial floor mats might need to withstand contact with harsh chemicals or abrasive substances instead. A standard rubber product might be cheaper but consider the cost of potential employee injuries or damage to your facilities and equipment.

Typically, rubber floor mats are made of foam rubber instead of solid rubber. In part, that’s because foam rubber has a cellular structure. Open-cell foams allow liquids and gases to pass through; closed-cell foams prevent their passage. Foam rubber also comes in different durometers, a measure of hardness. Softer rubber provides more cushioning, and harder rubber provides more impact resistance.

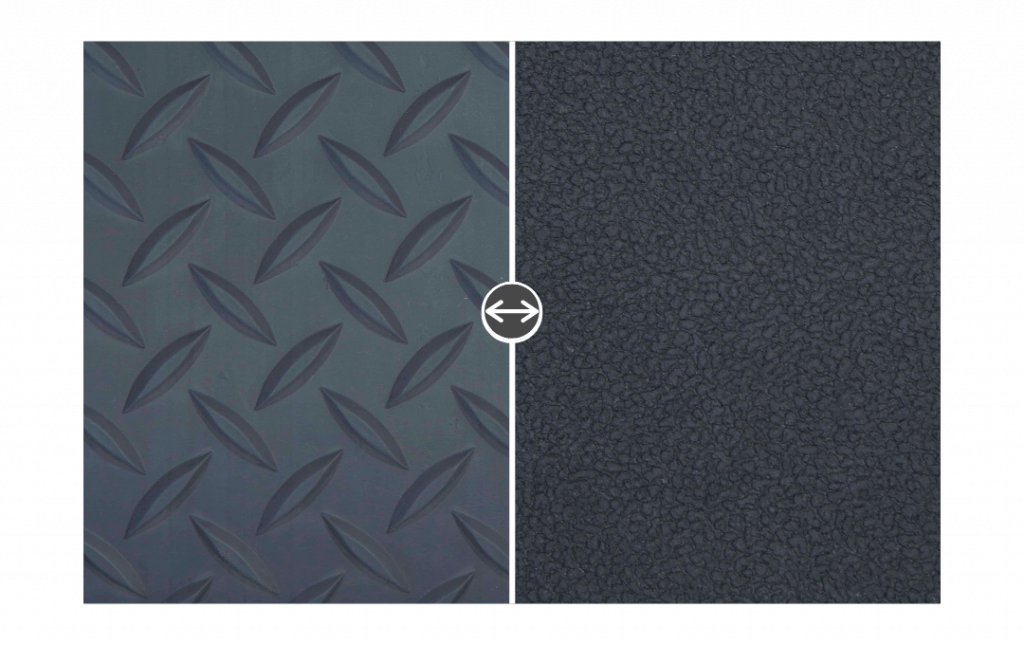

Most floor matting is black, but Elasto Proxy can source rubber flooring that is gray or brown, or that comes in custom colors. Some rubber matting is smooth, but commercial floor mats and industrial floor mats can have a pebbled texture instead for increased slip-resistance. Custom rubber floor mats can even have a diamond plate, or tread plate, pattern to catch mud, snow, or water from shoes or boots.

By taking the time to understand your requirements and offering you the best solution, Elasto Proxy can deliver greater value than what you’ll get from a commodity item. Custom rubber flooring isn’t needed for every application, but floor mats that you buy off-the-shelf might not fit properly inside a heavy equipment cabin, food processing facility, commercial kitchen, or factory floor.

Floor Matting Manufacturing: Lamination and Water Jet Cutting

Rubber flooring provides a measure of acoustic insulation, but some applications require greater noise control. The cabins in heavy equipment provide an example. For operators who sit above or near big diesel engines, noise from the engine bay can make it difficult to hear incoming communications. High decibel levels can also damage human hearing or violate occupational safety standards.

For applications like this, Elasto Proxy can laminate acoustic foams to rubber flooring. Typically, these foams are 3/8” (9.525 mm) or 5/8” thick (15.875 mm), depending on noise levels and decibel reduction requirements. Many different acoustical foams are available, and Elasto Proxy can help you select the right sound-absorbing, blocking, or damping solution.

Elasto Proxy can laminate acoustic insulation to rubber flooring that you cut yourself but consider the true costs of taking a do-it-yourself approach. Installers who make miscuts might need to throw away materials, and managers might not know how much waste is occurring. It’s difficult to make clean cuts with hand tools, and using a cardboard template is imprecise because the edges wear away over time.

Whether you need floormats with or without laminated insulation, Elasto Proxy uses water jet cutting to create custom solutions. There’s no tooling to wait for or pay for, and we can support you from prototyping through production. With water jet cutting, you’ll get clean, precise cuts every time. That’s good news if you need floor mats that fit the arms of gas or brake pedals, or bolt holes for cabin seats.

Standard and Custom Floor Mats

Depending on what you need, Elasto Proxy can provide you with standard or custom products. FM-500-60-ZM and FM-625-50-ZM are standard products you can get samples of by requesting the Elasto Proxy Insulation Bag.

FM-500-60-ZM contains a single layer of acoustical foam that’s bonded to a sound barrier. The top of this barrier material features durable, wear-resistant floor matting with a diamond plate design. Applications include floor mats and flooring in trucks, buses, construction equipment, and agricultural machinery. FM-500-60-ZM is also a good choice for runners and anti-fatigue mats.

FM-625-50-ZM features a weather-resistant pebbled surface and provides superior impact strength. Applications include floor mats in heavy equipment and mining equipment, as well as toolbox liners and trailer wall liners. The polyethylene foam that’s used meets flammability specifications for the heavy equipment industry.

Industrial Floor Mats and Commercial Floor Mats from Elasto Proxy

Do you need rubber floor matting for industrial or commercial applications? Elasto Proxy distributes rubber flooring materials, but we can also fabricate custom solutions that can help you to reduce waste and increase efficiency. Plus, when you order custom floor mats from us, we can kit them with the other rubber parts you need – and even in the order of installation.

Ready to learn more? Talk to Our Team