The differences between commodity rubber and specialty rubber are too important to ignore.

Are you designing custom seals, gaskets or insulation? Do you need help choosing the right rubber for the job? It’s not enough to ask a fabricator or distributor for “black rubber”. After all, most industrial rubber products are black, and an elastomer’s color doesn’t tell you about its performance properties, such as temperature resistance.

There’s also more than one version of a rubber compound. Examples include EPDM, nitrile, neoprene, silicone, SBR, and natural rubber. They’re called compounds because they don’t have just one ingredient – such as the carbon black that gives most industrial rubber products their color.

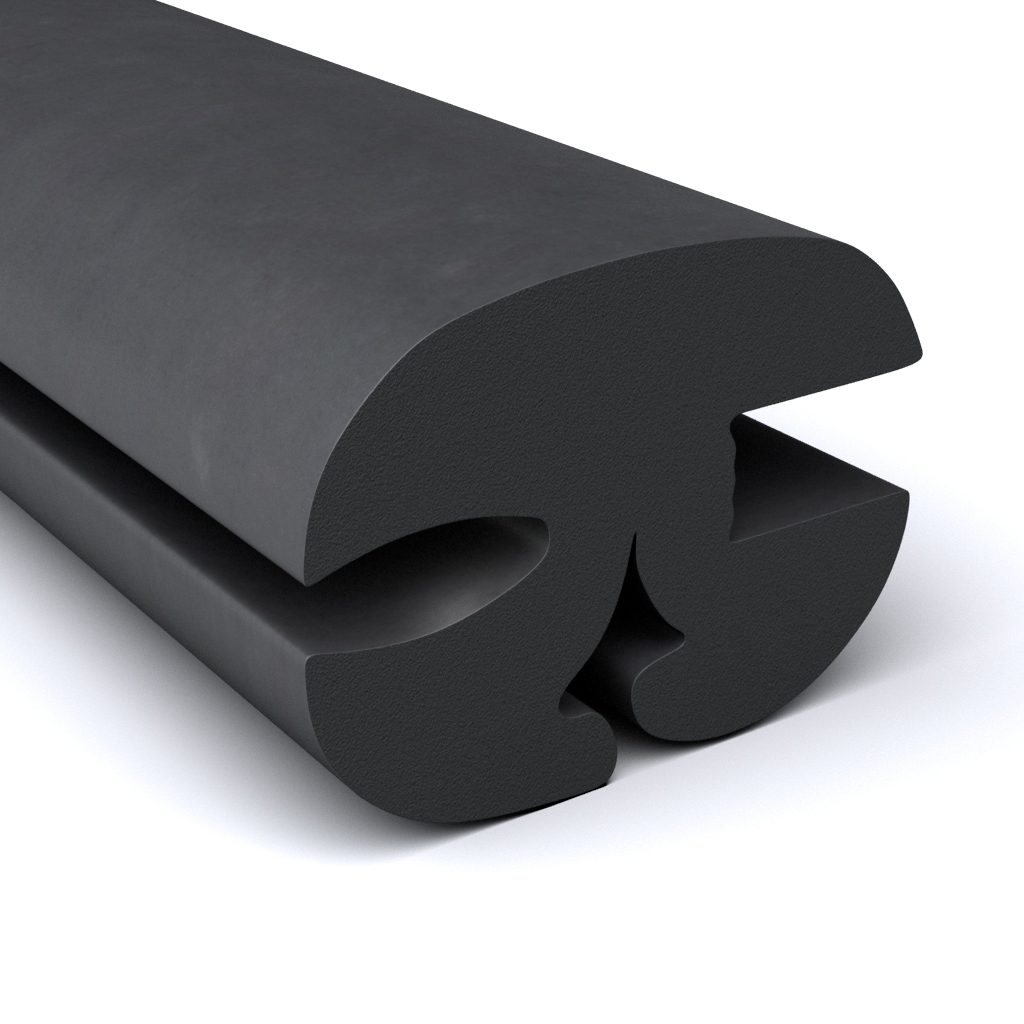

One of the ways that versions of a compound differ is durometer, a measurement of hardness. Elastomers can be divided into sponge rubber and solid rubber materials, too. Still, that’s not all there is to think about. You can choose a commodity rubber, or you can choose a specialty rubber. So, what’s the difference?

What is commodity rubber?

Commodity rubber is used in a wide range of seals, gaskets, and insulation. From door gaskets and window seals to floormats and grommets, commodity rubber meets typical performance requirements. Different compounds have different properties, but the properties you get are typical for that compound.

Because commodity rubber is produced in higher volumes using standard tooling, it usually costs less and has greater minimum order quantities (MOQs). Commodity rubber is often easier to source than specialty rubber, and you probably won’t have to wait as long for sheets, extrusions, or finished rubber products.

What is specialty rubber?

Specialty rubber is used in select applications, typically to meet more demanding requirements. Whether it’s to achieve greater levels of performance or to meet industry or regulatory standards, specialty rubber costs more and generally has higher MOQs. That means you might have to buy more material than you need.

Sometimes, the price of specialty rubber is higher because the inputs are more expensive, the testing requirements are challenging, or the tooling that’s needed is specialized. Plus, lead times may be longer because a supplier doesn’t keep the material on-hand.

Do you always need specialty rubber to meet an industry standard?

Some types of specialty rubber meet industry or regulatory standards. For example, there are rubber compounds that meet the requirements of UL 50, a standard from Underwriters Laboratories (UL) about enclosures for electrical equipment in non-hazardous areas.

Just because you’re designing a UL 50 enclosure doesn’t mean you need UL 50 rubber for the gaskets, however. That’s because UL 50 applies to the entire enclosure and not to individual components such as seals, gaskets, and insulation. This is a key distinction.

If your enclosure can meet all of UL 50’s requirements without using a UL 50 gasket material, you might be able to use a less expensive commodity rubber instead. Ultimately, it depends on your design – and whether enclosure sealing was a consideration or an afterthought.

Where can designers get help with comparing commodity rubber vs. specialty rubber?

As this article explains, asking for “black rubber” won’t get you what you need, and putting a standard like UL 50 on your schematic could add unnecessary costs to your project. For help with material selection, including commodity rubber vs. specialty rubber, talk to Elasto Proxy.

If you use a CAD application like SolidWorks®, our solutions providers can even send you DWG files of standard rubber profiles that you can drop into your design. We can also send you PDF versions of profile schematics instead. With help like this, you can save time and money for your next project.

Don’t wait to get started. Otherwise, you might find that you need to use a more expensive specialty rubber because a commercial-grade compound can’t support constraints that have been designed-in. By talking to our team early in your design process, you can make life easier and your products better.