Olivia’s humor had an edge. “The only time I get to see you smart young engineers is when you need to know something,” the Operations Manager laughed. “Now, instead of coming to see how things work on the factory floor, we’re talking through computer screens.”

“Thanks for meeting with us on this video call,” Eric said politely. He introduced Jenny-Lynn from Elasto Proxy and explained how JL was helping him fix the leaky door gaskets on the company’s new tractors. He described his visit to Patrick and what he’d learned about true costs and manufacturing waste.

“Patrick is a peach,” Olivia joked. Then she narrowed her eyes. As the first woman Operations Manager at the agricultural equipment company, she had faced her share of doubters. “What makes you think we waste anything over here?”, Olivia asked sternly. Then she smiled and held up a finished gasket from the company’s current supplier. As always, she’d come prepared.

“These gaskets are hard to install and we’ve been replacing a lot of them,” the Operations Manager admitted. “I don’t know what’s wrong with them, but they’re just a commodity item even if we are at risk of having to issue a service bulletin. I’d like to understand the root cause, but we’re talking about a $10 gasket on a million-dollar tractor.”

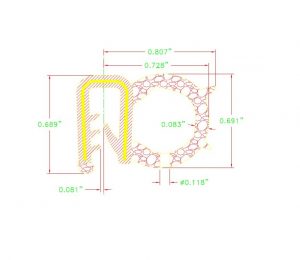

As Olivia moved the gasket closer to her video camera, Jenny-Lynn could see that there was too much glue in the gasket’s corners. The Elasto Proxy solutions provider explained that this was making the gaskets harder and more difficult to compress. That wasn’t the only problem either.

“When Elasto Proxy looked at Eric’s drawings,” JL explained, “we noticed that the gaskets are too tall. That puts excessive pressure at the hinges and makes the doors difficult to close. Over time, the rubber gets crushed and won’t bounce back when the door is opened. That’s called compression set.”

Olivia nodded her head. “It makes sense,” she said, “but that’s a problem for Engineering – not Operations. Here on the assembly line, we came up with a workaround. We’re installing shims. Now there’s less rework.” She folded her arms and smiled proudly.

“Olivia,” Jenny-Lynn asked evenly, “what percentage of the door gaskets do you still have to rework?”

“I’d say about 40 percent,” Olivia said. “But what’s the big deal? It’s just a $10 gasket. It’s not like it’s a diesel engine or anything.”

“Eric tells me that your installers work five days a week,” JL continued. “With a 40% rework rate, it’s like asking them to redo all of their work from every Monday and Tuesday. The price you pay for your current gasket is just $10, but those aren’t your true costs.”

“Where are you going with this?”, Olivia asked impatiently. “I don’t want to see our workers waste their time but understand that we build 10 tractors a day. If we rework all of the door gaskets over a two-day period, that’s only 20 gaskets. And $200 is just a blip on a balance sheet.”

“Agreed,” JL said. “But let me ask you another question. How long do gasket installs and removals take?”

“That I couldn’t tell you,” Olivia replied. “We don’t worry about it. It’s not like it’s a welding operation. That’s where things get expensive – and good welders are hard to find.”

“That’s for sure,” Jenny-Lynn agreed. “What’s the fully burdened labor rate for a welder these days?”, she continued. “If you add together the hourly rate with their benefits, I bet it’s pretty expensive.”

“You’re not kidding,” Olivia replied. “Our welders have a fully burdened rate of $100/hour. We get our money’s worth though. When they’re not welding, they’re do things like installing gaskets.”

JL smiled. “Sounds like you’re ready to carry the puck to the zone when it comes to true costs,” she said.

Previous Chapters