Vibration mount damping, isolation, and selection is easier when you work with Elasto Proxy.

Vibration mounts protect vehicles, machinery, and equipment from the damaging effects of vibrations, repeated back-and-forth movements (oscillations) that can accelerate wear, consume excess power, raise safety issues, and result in unplanned downtime. Anti-vibration mounts, as they’re also called, are designed to withstand specific loads and come in different shapes, sizes, and materials of construction.

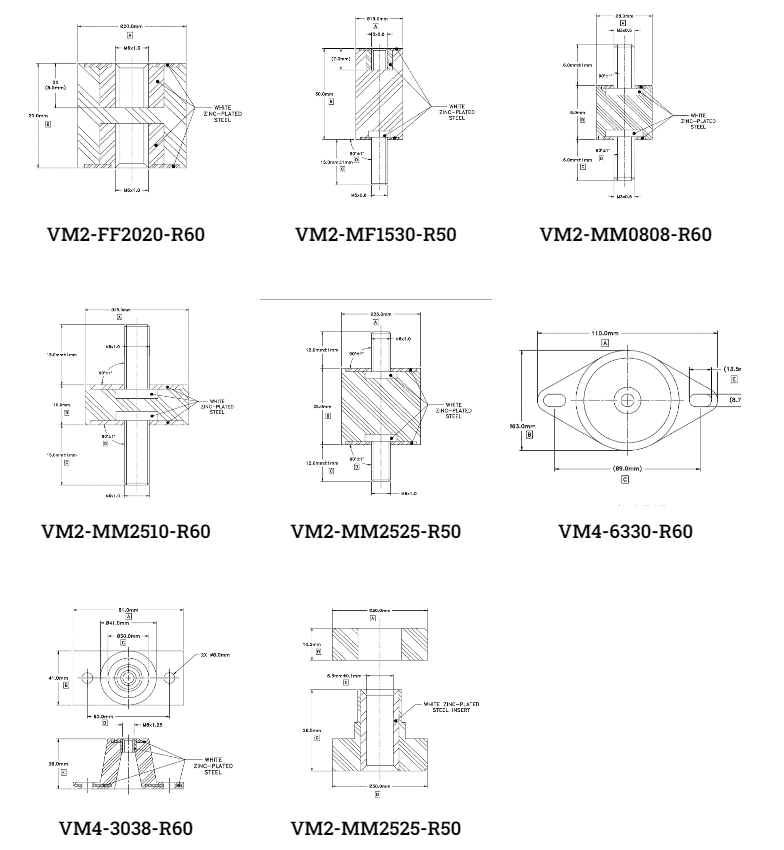

Keep reading to learn more about these rubber-to-metal bonded assembles or see our standard products.

Vibration Damping vs. Vibration Isolation

Vibration mounts consist of a rubber jacket and a metal core with tapped holes for fasteners. Through vibration damping or vibration isolation, the rubber jacket dissipates the vibrational energy that causes oscillations. Although damping and isolation are sometimes used interchangeably, these two terms are not the same. Practically speaking, vibration damping reduces vibrational energy while vibration isolation prevents the transmission of this energy in the first place.

Typically, vibration isolators are installed near sources of vibrational energy such as engines, motors, and generator sets. Vibration dampers are installed elsewhere on vehicles, machinery, and equipment, and in a distributed fashion. That’s because vibrations are transmitted through structural members such as metal frames and body panels. Vibration dampers dissipate energy from these transmissions and, unlike vibration isolators, don’t depend on changing the natural frequency at which an object vibrates.

Vibration Mount Selection

Selecting the right vibration mount isn’t just about choosing a vibration damper instead of a vibration isolator, or vice versa. Ask yourself these questions, and evaluate these five considerations.

- System weight and weight distribution

- Maximum loads and deflection

- Installation locations

- Materials of construction

- Shape and sizes

The following sections explain.

#1 System weight and weight distribution

Heavier vehicles, machines, and equipment usually require larger or more numerous vibration mounts. You may also need larger or more numerous anti-vibration mounts if the weight of a system isn’t distributed evenly, or if there is more weight in some locations. For example, a dump truck that is fully loaded with rocks is probably heavier in the dump bed than in the cabin.

#2 Maximum loads and deflection

Vibration mounts can withstand different types of loads: compression, shear, torsion, tension, and/or buckling. By determining the types and maximum loads that your application needs to withstand, you can compare vibration mounts based on their load-deflection characteristics. This information may be listed as maximum values on product specification sheets or given as a load-deflection curve.

#3 Vibration mount installation locations

As their name suggests, vibration mounts are designed to be mounted on vehicles, machinery, and equipment. Although isolators are installed at or near the source of vibrations, dampers are installed where vibrations need to be reduced, such as where vibrational energy that produces noise is transmitted through a vehicle chassis. Ease of installation is also an important consideration.

#4 Materials of construction

The rubber that’s used in vibration mounts is available in different compounds and durometers. The compound determines the rubber’s environmental resistance, such as to machine oils. The durometer affects the rubber’s ability to recover from loads and, importantly, to reduce vibrations. Harder, stiffer rubber has a higher load capacity but is not as effective as softer rubber in reducing vibrations.

#5 Vibration mount shapes and sizes

Vibration mounts come in various shapes and sizes. The shape matters because rubber that is under different types of loads needs to dissipate energy across multiple planes and directions. Products with flatter surfaces reduced localized stress, but the shape also affects stiffness. Sizes can range from small vibration mounts for electronic instruments to larger anti-vibration that are used in railcar applications.

Elasto Proxy supplies standard vibration mounts and is a one-stop shop for manufacturers who need rubber products that include molded rubber parts, thermal and acoustic insulation, and finished gaskets. Check out our standard vibration mounts or contact us to discuss your specific application.