Clyde Sharpe

President of International Sales, Elasto Proxy

Does your company have too many suppliers? How well do you understand the capabilities of each of your vendors? These questions seem separate, but they’re interrelated. Your answers can benefit your own buyers and managers, as well as the suppliers who serve them.

Traditionally, manufacturers divided purchases among many different vendors. Buyers focused on supplier prices, but without understanding the internal costs of maintaining a large vendor base. Tracking a multitude of purchase orders, invoices, and deliveries wasn’t the only challenge, however. Quality and reliability suffered if buyers didn’t fully understand what suppliers could and couldn’t do.

When buyers reduce their supply base, they strengthen their supply chain. At the same time, suppliers who offer one-stop sourcing can also increase business. This is good for them – and good for you, too.

Reducing the Vendor Base

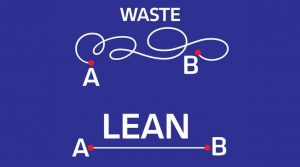

Reducing the vendor base is a principle of lean manufacturing, a set of production practices that seeks to eliminate waste and deliver quality products on-time, at the lowest production costs, and according to customer needs. Companies that apply lean principles to their purchasing practices buy from fewer and more dependable suppliers, developing partnerships and building trust.

Lean buyers take the time to fully understand each supplier’s capabilities. Lean managers understand that “value” means more than low prices, and seek suppliers who can help improve quality, enhance functionality, and reduce costs. So how lean is your company’s procurement process?

Strengthen the Supply Chain

Businesses that reduce their vendor base strengthen their supply chain, as a case study of one our specialty vehicle customers proves. When Volvo of Ontario asked Elasto Proxy what more we could do for them, my colleague John Rye described our technical design and custom fabrication capabilities.

Volvo’s Ontario division reduced its vendor base repeatedly, but Elasto Proxy made each cut and even landed larger contracts. The specialty vehicle manufacturer has moved these operations to the United States, but Elasto Proxy continues to provide high-quality rubber and plastic parts on-time and according to specification.

Increase Business

Like many multinational corporations, Volvo maintains production facilities beyond just Europe and North America. So when Volvo of Brazil needed a supplier that could strengthen their supply chain, they approached Elasto Proxy because of our work for Volvo in Canada and the U.S. As Elasto Proxy seeks new partners in international markets, we’re proud to showcase Volvo of Brazil as an example of how we’re meeting sealing challenges in South America.

One-stop sourcing means more than just supply chain strength. By helping Volvo of Brazil to reduce its vendor base, Elasto Proxy is learning lessons that can benefit other partners in the many industries we serve. Does your company have too many suppliers? Do you fully understand the capabilities of each of your vendors? Our advice is to choose a partner – not just a provider. How may we help you?