Doug Sharpe

President of Elasto Proxy

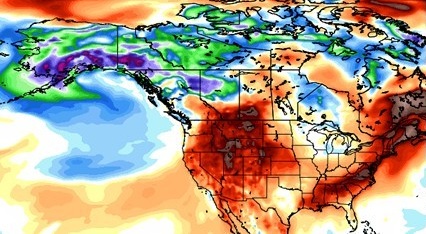

Did you have a cup of coffee this morning? How about a glass of orange juice. If you enjoyed either of these beverages, thank a trucker. Each day, the commercial trucking industry moves billions of dollars’ worth of commodities between the United States, Canada, and Mexico. For long-haul truckers who drive from places like Miami, Florida to Montreal, Canada, the trip lasts days and involves extreme changes in temperature – especially during the winter months.

For driver and vehicle alike, temperature changes can be challenging. Tractor trailers contain plenty of rubber and plastic parts – not just the tires. If a door or window seal is made of a compound that can’t handle hot or cold temperatures, the seal may fail. Farmers, road crews, and construction workers face this problem, too, even though their vehicles travel much shorter distances. Outdoor temperatures can rise and fall rapidly, so makers of mobile specialty vehicles also need dependable sealing solutions.

Service Temperature of Elastomers

Rubber softens at high temperatures and becomes hard as a hockey puck at low temperatures. Many different elastomers are available, so how do you choose the right rubber for your sealing application?

With outdoor products such as door and window seals, you need to consider the service temperature for starters. This chart from our website lists temperature range for various types of rubber.

| Material Compound | Minimum Temperature | Maximum Temperature |

| SBR | -85° F | +158° F |

| Natural Rubber | -85° F | +158° F |

| EPDM | -80° F | +300° F |

| Neoprene | -65° F | +225° F |

| Nitrile | -55° F | +275° F |

| Urethane | -70° F | +250° F |

| Silicone | -180° F | +525° F |

| Viton | -40° F | +500° F |

Service temperature isn’t the only factor to consider, of course, but let’s start with the basics.

Rubber Seals at Low and High Temperatures

At low temperatures, elastomers do more than harden. They become less flexible. If they reach their brittle point, they may even crack. That’s what happened to the rubber O-rings on the Space Shuttle Challenger in a 1986 tragedy that claimed the lives of seven astronauts. NASA officials believed the seals were suitable for cold weather, but the O-rings were unable to withstand sub-freezing temperatures.

The weather at Cape Canaveral, Florida was unusual on that day, more like Montreal than Miami. But high temperatures can also cause seals to fail. When the temperature of an elastomer approaches its upper service limit, the rubber may undergo chemical changes that are irreversible.

With each 10° C (18 °F) increase in temperature, the rate of some chemical reactions doubles. Again, consider the case of a trucker who is northbound bound from Miami to Montreal in the middle of a (typical) winter. If extreme cold will reduce the life of a door seal that’s helping to protect a valuable shipment, isn’t the cost of a compound with a wider temperature range a sound investment?

Elastomer Performance and Predictability

Even if a seal doesn’t fail, elastomer performance becomes less predictable when rubber reaches the limits of its service temperature range. So does that mean that we can predict how a compound will expand, contract, and recover with changes in temperature? Yes, but this is why there’s more than just temperature range alone to consider. Each material handles these changes differently.

In my next blog entry, I’ll discuss a concept called the coefficient of linear thermal expansion. So drink your orange juice – and grab a cup of coffee – before trucking over next week. In the meantime, do you have any questions about seal selection and service temperature? Please let me know by commenting below, or connect with me on LinkedIn.