Paulo Arruda

Purchasing and Logistics at Elasto Proxy

Part tolerances are allowable variations in the dimensions of manufactured components. They are expressed as plus or minus values, or as a range of measurements. If a part is out of tolerance, problems may occur. For example, if a rubber door seal on a machine is out of tolerance, the door may be difficult to shut or fail to provide proper sealing and insulation.

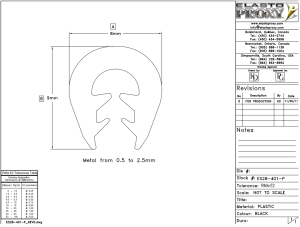

Engineers and product designers understand part tolerances for metal components, but may be less familiar with tolerances for rubber parts such as door seals. Rubber has different properties than metal, of course, and is more sensitive to environmental conditions such as temperature. The type of rubber and the kind of tooling that is used during manufacturing also affects part tolerance.

Solving Part Tolerance Challenges

Sometimes, an engineer or product designer specifies a tolerance that would be fine for a metal part, but not for a rubber profile. As an experienced custom fabricator, Elasto Proxy can review your drawings or CAD files, and suggest modifications. By examining tolerance tables from the Rubber Manufacturers Association (RMA), our technical team can then recommend solutions that support your product design.

The RMA is well-known for its work regarding tire safety, but this trade organization supports many manufacturers of rubber products. The RMA’s tolerance tables help during part design and production, and provide a “common language” that the entire supply chain can understand. Buyers of industrial rubber products don’t need the in-depth knowledge of a custom fabricator, but it helps to understand the basics.

Molded and Extruded Parts

The RMA Handbook contains tolerance tables for both molded and extruded rubber. Molding and extrusion are different processes, but both subject rubber parts to physical changes. For example, during molding, the rubber expands as it vulcanizes. The recipe for the rubber determines the temperature at which curing or vulcanization occurs. Later, when the molded part cools, it shrinks.

Extrusion also causes changes in part size, and extruded parts can swell or shrink depending on the compound that’s used. As extruders know, the shape of the die isn’t the shape of the final part. There are other considerations, too. Solid extrusions are denser and easier to control. Extruded sponge and foam exhibit larger variances because of the chemical reaction that creates the cavities.

Tolerance Types and RMA Classes

As the RMA Handbook indicates, extruded parts have tolerances for shape or cross-section, cut-length, and angle cut. In the case of cut-lengths, it’s important to remember that rubber stretches. Tight tolerances are possible with metal channels, but not with rubber extrusions that expand or contract with temperature changes. Also, the tolerances on angle cuts used with spliced gaskets aren’t the same as the tolerances for cut lengths. Consequently, each process has its own tolerance chart.

Buyers of industrial rubber products also need to understand that the RMA Handbook divides, for example, solid extruded parts into three classes: high precision (1), precision (2), and commercial (3). That’s why when you receive a quote from us, you may see a line such as “per RMA-E2”. This refers to the specific RMA tolerance table (Table 13, which uses a lettered identifier of E), as well as the precision class (2).

How Can We Help You?

Do you have questions about part tolerances for rubber seals and insulation? Would you like to learn more about molding and extrusion, and why choosing the right rubber is so important? Do you have questions about RMA tolerance tables, such as which ones apply to your design? For over 25 years, Elasto Proxy has been helping partners solve technical design and custom-fabrication challenges.

Please contact us for more information, or join the conversation on our social media channels. Look for a post with a link to this blog entry on LinkedIn, Facebook, Google+, and Twitter. Elasto Proxy has a YouTube channel, too. Finally, please subscribe to our free e-newsletters. They’re a great source of information delivered right to your email inbox, and they provide links to blog entries like this one.