Happy National Aviation Week! Elasto Proxy is AS9100D certified and supplies non-critical aircraft parts.

National Aviation Week runs from Monday, August 19th through Sunday, August 24th, 2024. This week-long celebration of human flight starts with National Aviation Day, the anniversary of the birth of Orville Wright. Along with his brother Wilbur, Orville designed and built the first airplane, which was powered by a 12 hp (9 Kw) gasoline engine. Known as the Wright Flyer, this propeller-driven aircraft first flew at Kitty Hawk, North Carolina, on December 17, 1903, with Orville at the controls.

Fast forward to today. A single jet engine can produce over 30,000 hp (22,370 Kw). Moreover, a Boeing 747 has six million parts. Some are critical, meaning that their failure could have catastrophic consequences. Yet there are also non-critical parts that do not affect the immediate safety or structural integrity of the aircraft. These parts are still necessary, of course, but they don’t meet the definition of critical parts from sources like the U.S. Electronic Code of Federal Regulations (e-CFR).

Non-Critical Aircraft Parts from an AS9100D Manufacturer

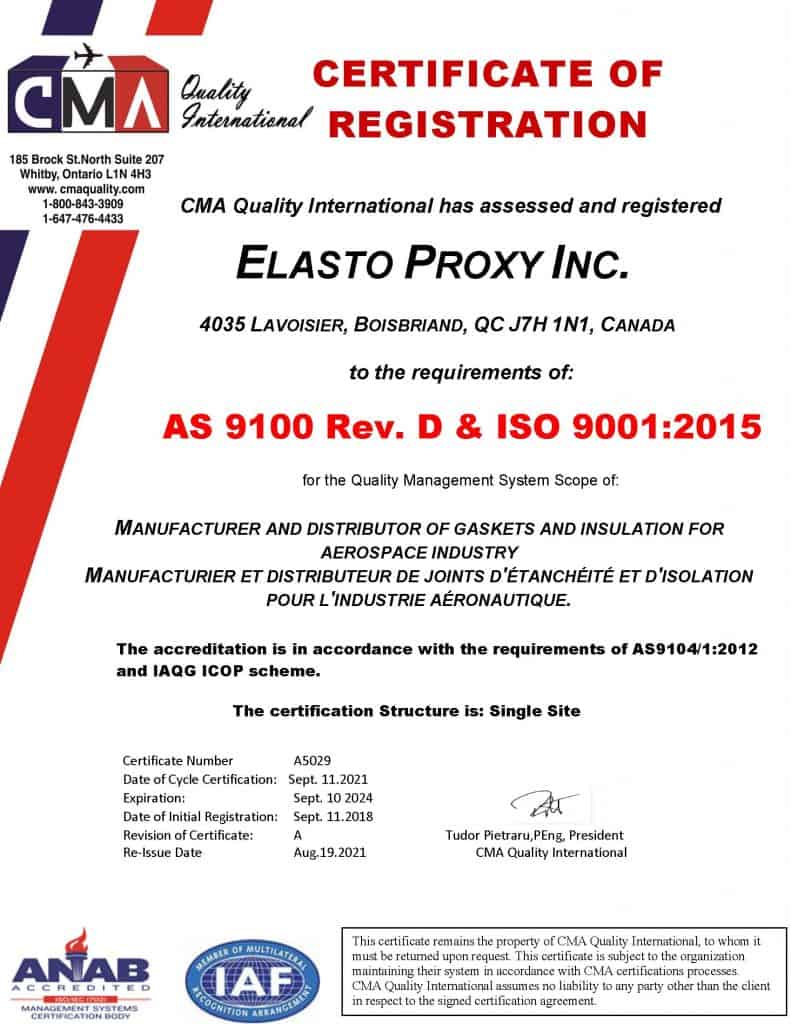

Elasto Proxy supplies non-critical aircraft parts and is an AS9100 Rev. D certified manufacturer and distributor of gaskets and insulation for the aerospace industry. We’re headquartered near Montreal, Quebec, Canada, the world’s third largest aerospace center. Montreal is the only place in the world where an entire aircraft can be assembled from locally manufactured components, including non-critical parts from our Boisbriand, Quebec facility.

Sealing and Insulation Solutions

Elasto Proxy specializes in fabricating low-to-medium volumes of rubber seals, gaskets, and insulation. In addition, we supply molded rubber and plastic parts, metal-to-rubber and metal-to-plastic assemblies, and sewn products. With our abrasive water jet cutting equipment, we can even fabricate non-critical aircraft parts made of metals, glass, and composites.

Non-critical aircraft parts are found throughout the aircraft and include components for:

- Cabin interiors

- Passenger comfort systems

- Exterior systems

- Non-critical electronics wiring

- Non-essential structural components

Let’s take a closer look.

Cabin Interiors

- Seats and Seat Covers: Passenger and crew seating has cushions and covers.

- Overhead Bins: Storage compartments are equipped with molded plastic handles and hinges.

- Cabin Lighting: General lighting systems within the cabin need optically clear lenses and push button controls.

- Window Shades: The blinds that passengers close to block incoming light are made of plastic sheets that are cut to size.

- Floor Mats: Rolls and sheets of rubber are converted into flooring solutions for the cabin, galley, and cockpit. For noise control, rubber flooring can be laminated to acoustic insulation.

Passenger Comfort Systems

- In-Flight Entertainment Systems (IFE): Video screens have molded rubber gaskets and audio systems have molded plastic parts.

- Passenger Service Units (PSUs): Overhead units with lights, air vents, and call buttons need environmental sealing and insulation.

- Lavatory Equipment: Toilets, sinks, and other amenities found in the aircraft’s lavatories all have rubber seals.

- Galley Equipment: Ovens, coffee makers, and storage units need to seal in food and beverages and seal out the environment.

Exterior Systems

- Non-Structural Fairings: Aerodynamic covers made of metal or composites smooth-out the airflow over parts of the aircraft that aren’t load-bearing.

- Access Panels and Doors: Thermoformed plastic panels provide access to non-critical areas for maintenance, such as the compartments for avionics or other electronics.

- Pitot Tube Covers: These Kevlar covers aren’t part of the flight system when an aircraft is airborne, but they protect pitot tubes when a plane is on the ground.

Non-Critical Electronics and Wiring

- Cabin Intercom Systems: Communication systems for announcements to passengers and between crew members need reliable rubber and plastic parts.

- Non-Essential Cabin Wiring: Electrical systems for non-critical functions like entertainment or passenger lighting use molded rubber grommets to protect wiring.

Non-Essential Structural Components

- Interior Paneling: Decorative or protective panels inside the aircraft cabin don’t contribute to the structural integrity of the aircraft, but they can provide acoustic insulation.

- Tray Tables: Fold-down tables that attach to the back of passenger seats are made of durable molded plastic that’s also easy-to-clean.

Celebrate National Aviation Week with Elasto Proxy

Elasto Proxy invites you to join us in celebrating National Aviation Week and hopes that the information in this article will help you to source the non-critical aircraft parts you need. Contact us for a quote if you work for an aircraft manufacturer or an aviation maintenance, repair, and operations organization (AvMRO).