Get bulb trim installation tips from Elasto Proxy. We supply trim seals to manufacturers.

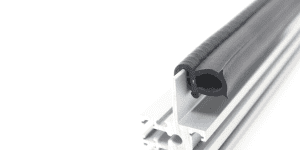

Bulb trim seals keep out air, water, dust, and noise. They are used in doors with radiused corners and consist of a compressible bulb and a solid retainer section. When the door is closed, the bulb is compressed to create a seal between the door and the jam. The trim or solid retainer section installs over the edge of the door and combines a finished appearance with edge protection. Applications for bulb trim seals include mobile equipment and enclosures for electronics and machinery.

In this “How to” article from Elasto Proxy, you’ll learn how to install bulb trim seals so that they won’t over-compress or kink. First, you’ll learn about materials and measurements for the bulb section. You’ll then learn how to specify the trim section of your seal. Along the way, we’ll cover some calculations and best practices for ordering and installing the industrial rubber products that you need. Bulb trim seals are sold in coils, but they also come cut-to-length to help you speed installation.

The Bulb

The bulb portion of a bulb trim seal is made of a sponge rubber that provides environmental sealing and resists compression set – the permanent, unrecoverable deformation of a seal after it’s been compressed, such as when a door is closed. Different materials are available, but EPDM and TPEs are often used.

- EPDM sponge rubber remains flexible at low temperatures and provides excellent resistance to weather, ozone, aging, water, and steam.

- Thermoplastic elastomers (TPEs) are also weather-resistant, but provide greater impact strength. TPEs are more expensive, but they’re also recyclable.

Both bulb materials have a hardness or durometer (Shore A) that’s medium-density. Generally, the shape of the bulb is round. If an extended lip is required, choose a seal with a teardrop-shaped bulb instead. You can also specify bulbs that resemble a half-moon with a flat bottom. Bulb location varies. Depending on how the door swings open, the bulb is usually atop or side-by-side the trim.

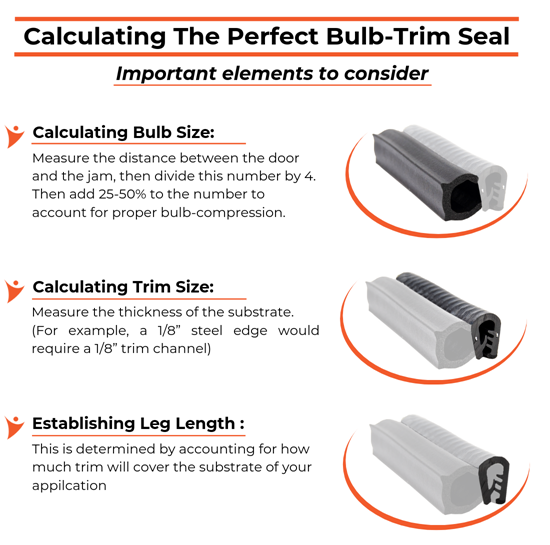

Bulb size is especially important. To determine this measurement, find the average jam dimension. An easy way to do this is to place some modeling clay in each corner and then close the door to compress the clay. Next, insert calipers into the clay and record the measurement for each corner. Now divide this number by four to get the average jam dimension.

To account for bulb compression, add 25% to 50%. Most bulb trim seals are designed to compress by this amount. The percentage that you use doesn’t have to be exact, but it needs to be close enough. Remember that over-compressing the bulb will not create a better seal. In fact, over-compression can reduce seal life and cause compression set.

The Trim

The trim portion of a bulb trim seal is made of a solid rubber like EPDM or TPE, or a plastic like PVC – a strong, lightweight material that’s easy-to-handle. Depending on your requirements, the durometer for the trim section can be harder (or softer) than for the bulb section. Rubber trim is usually black, but comes in different colors to support various product designs. Trim can have a smooth or textured finish, too.

For additional gripping, choose a solid retainer section with interior tongues. To help absorb impact, choose trim with steel wire or segmented steel cores. Cutting this type of trim in-house may seem cost-effective, but using a hand tool can result in poor-quality cuts and material waste. By ordering cut-to-length products from Elasto Proxy, you can save both time and money.

Regardless of the cutting method you choose, you’ll need to specify two trim dimensions – edge thickness and leg length – in order to get the bulb trim seals that you need. The edge thickness of the trim needs to match the thickness of the door’s edge. Do not add a percentage like you did with the bulb. Leg length indicates how much the trim will cover the flange. As a rule, shallower flanges require shorter legs.

Choose trim with a minimum edge radius that meets your application requirements. Unlike some other industrial rubber products, the trim in a bulb trim seal isn’t designed for 90-degree corners. If you use bulb trim seals in this way, the corners will kink and the kinks will form valleys that leak. When you press the trim portion into place then, avoid any type of buckling in the corners.

Get More Bulb Trim Installation Tips

Elasto Proxy can review your designs for dimensions like edge radius, and can suggest improvements for superior sealing and insulation. We help you with material selection, too. Importantly, the value-added manufacturing that we offer can help you to avoid problems (such as over-compression and kinking) that can occur during product installation. To learn more about bulb trim seals from Elasto Proxy, contact us.