Dual durometer rubber products have different areas of hardness as measured on the Shore A scale. The harder rubber attaches to a substrate and provides impact resistance. The softer rubber compresses to fill a gap and provides sealing. Water jet equipment can be used to cut dual durometer rubber to length, and the finished gasket can be installed over a flange or attached with fasteners or adhesive tape.

Applications for dual durometer rubber products include door and window seals. For example, a dual durometer window seal can have a harder rubber section that attaches to a window frame and a softer rubber section that faces the window glass. With door seals, the harder section attaches to the door frame and the softer section fills the gap between the frame and closed door.

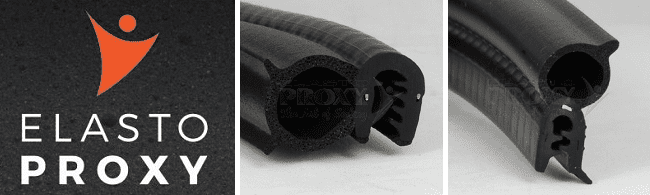

Elasto Proxy supplies manufacturers with coils, cut lengths, and finished gaskets made from dual durometer rubber. This article provides answers to frequently asked questions (FAQs) about these industrial rubber products and is a good place to start if you’d like to learn more. To request a quote, or to your specific sealing application, contact us.

How are dual durometer products made?

They are co-extruded. During this manufacturing process, two (or more) materials are pressed together and pushed through the same die to produce a single product. Standard co-extrusions are typically faster to produce since they use an existing die. Custom co-extrusions have longer lead times since there is special tooling to design, machine, pay for, and wait for.

How hard or soft can the rubber get?

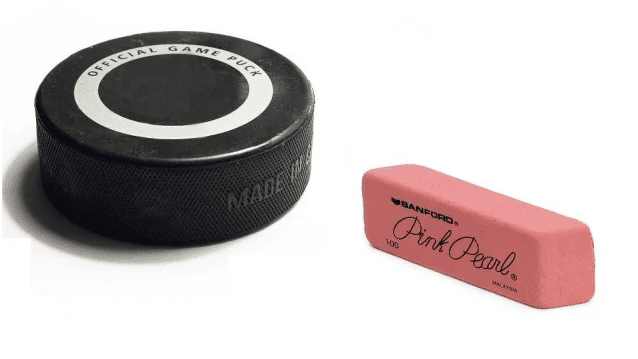

Rubber can be as soft as a pencil eraser or as hard as a hockey puck. Softer rubber has a lower durometer, and harder rubber has a higher durometer. Remember, however, that that softness or hardness of rubber can vary by temperature. If you leave a pencil in your car on hot July day, the eraser becomes even softer. If you put a hockey puck in a freezer, it becomes even harder.

Do dual durometer extrusions contain different types of rubber?

Yes, in the sense that most dual durometer products contain both sponge rubber and solid rubber. Sponge rubber has a cellular structure and is usually softer. Solid rubber does not have a cellular structure and is usually harder. Remember, however, that durometer – and not whether rubber is solid or sponge – is the measure of hardness.

What about rubber compounds?

Dual durometer extrusions can be made of different rubber compounds, or even a rubber and a plastic material. Typically, however, dual durometer rubber is made of same compound. EPDM, a weather-resistant elastomer, is often used for sealing doors and windows. Thermoplastic elastomers (TPEs) can be used instead but come with tradeoffs. For example, TPEs cost more than EPDM but are recyclable.

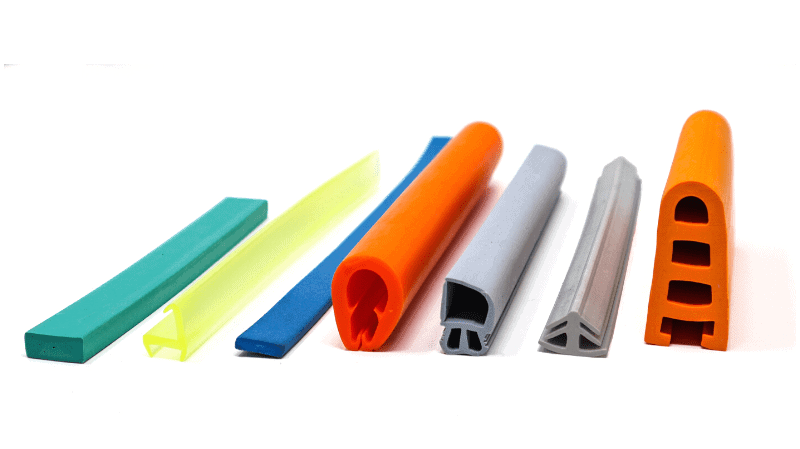

Are all dual durometer extrusions black in color?

No. Although most EPDM rubber is black, TPEs supports custom color matching. That may be important if you work in an industry such as heavy equipment, and you need the door and window seals to match a product’s larger color scheme. Dual durometer extrusions can also come in different colors so that it’s easy for installers to determine which section is for attachment, and which section is for sealing.

Which types of products are made of dual durometer rubber?

Bulb trim seals are usually made of dual durometer rubber. Often, the compressible bulb section is made of a softer sponge rubber. The trim, or retainer, section is made of harder solid rubber instead. Both sections may be made of the same material (such as EPDM) or of different materials (such as EPDM and PVC). Sometimes, the trim contains metal for added impact resistance and tongues for added gripping.

How do you order dual durometer rubber products?

Elasto Proxy supplies manufacturers with dual durometer products and can assist personnel from engineering, purchasing, or operations with product selection. To get started, contact us.