The difference between foam rubber vs. sponge rubber is about how these gasket materials are made and the type of sealing barrier they provide. You don’t have to be a scientist to understand these differences, but you do need to make the right choice if you’re an engineer or a technical buyer.

Otherwise, you risk choosing a gasket material that could fail in the field when you need it the most.

What does gasket failure look like? If you make the wrong choice between foam rubber vs. sponge rubber (or choose the wrong compound or durometer), your seal could leak or over-compress. The rubber might also shrivel up or become brittle.

At Elasto Proxy, we recommend basing material selection on MTAP, an easy way to remember Material (M), Temperature (T), Application (A), and Pressure (P). Contact us for custom gaskets that provide sealing success or keep reading to learn about the differences between foam rubber and sponge rubber.

Foam Rubber

Let’s start by taking a look at how foam rubber is made and how it’s used.

How is foam rubber made?

Foam rubber is made with what’s known as a blowing agent. Typically, this is a gas or a chemical that produces a gas. The result is a small mass of bubbles (foam) in a mixture of the following ingredients.

- Polyols

- Polyisocyanates

- Water

- Flame retardants

- Fillers

- Colorants

What are polyols and polyisocyanates? They’re liquid polymers that generate heat when they’re combined with water. By controlling the amount of foaming and adjusting the volume of water, it’s possible to adjust the foam rubber’s end-use properties.

The type of blowing agent is critical, but the type and amounts of liquid polymers are also important because they can produce either flexible or rigid foam rubber.

How is foam rubber used?

The way that foam rubber is used depends on whether the material is flexible or rigid. Yet it also depends on the specific type of elastomeric compound. Consider these two examples.

- Flexible polyurethane foams are used for vibration control and shock absorption. Applications include hood gaskets, shock absorbers, and vibration isolators.

- Rigid polystyrene foams are strong, lightweight, and moisture-resistant. Applications include filters, especially if bactericides or fungicides are added.

These are just a few applications for foam rubber, and there are many other types of products for specific applications. For example, did you know that Elasto Proxy has fabricated foam rubber into elastomeric pads for the vacuum tooling used in stone countertop manufacturing?

Sponge Rubber

Now that you know the basics of foam rubber, let’s take a look at how sponge rubber is made and used. But first let’s look at the difference between open-cell and closed-cell materials.

How is sponge rubber made?

There are two types of sponge rubber: open-cell and closed-cell.

- Open-cell sponge rubber contains open, interconnected pockets that permit the passage of air, water, or chemicals when the rubber is not compressed.

- Closed-cell sponge rubber contains closed, balloon-like cells that hold nitrogen gas. This gas prevents the passage of air, water, and chemicals when the rubber is not compressed.

In other words, the type of cells (open or closed) either permit or prevent the passage of liquids or gases. But isn’t the nitrogen that’s used in closed-cell sponge rubber a type of gas? And aren’t gases used in foam rubber? It’s time to take a deeper dive.

Yes, nitrogen is a gas; however, it doesn’t produce foam. Moreover, the foaming process that’s used with foam rubber creates mostly open cells. The closed cells that are produced are too few in number for foam rubber to resist water absorption.

So how is open-cell and closed-cell sponge rubber actually made?

How is open-cell sponge rubber made?

To produce open-cell sponge rubber, sodium bicarbonate is added to other ingredients in a heated mold. As the uncured sponge rubber rises like a cake, the baking soda creates open, interconnected cells.

How is closed-cell sponge rubber made?

To produce closed-cell sponge rubber, a chemical powder that decomposes under heat and pressure is added to a mixture of ingredients. The nitrogen gas that’s released helps to give closed-cell sponge rubber its strong compression set and recovery characteristics.

How is sponge rubber used?

Sponge rubber profiles are fabricated into finished gaskets for a variety of applications. For example:

- In the heavy equipment industry, sponge rubber bulb seals are used for doors, hatches, and enclosures.

- In the medical industry, sponge rubber is used for patient lifts, hospital room equipment that helps people with limited mobility to get up or sit up.

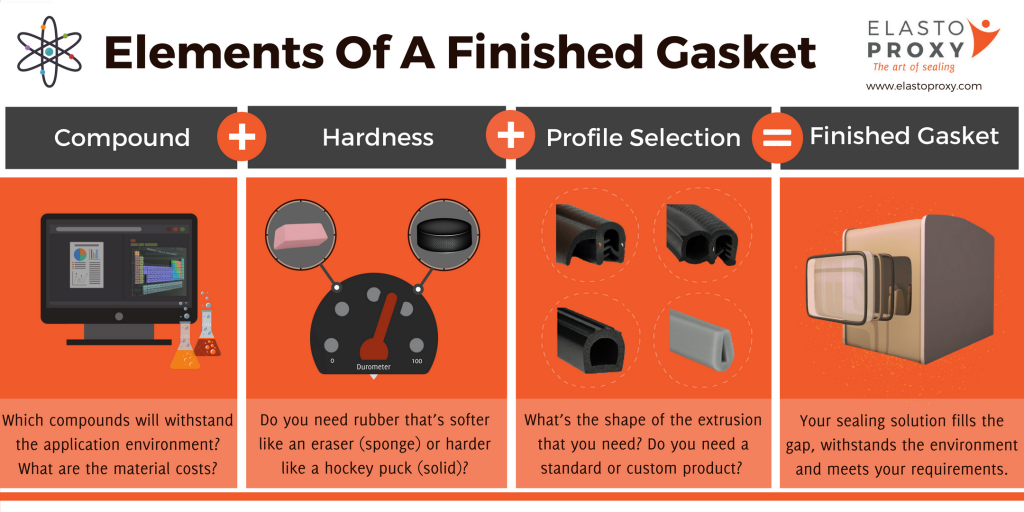

These are just a few of the many applications for sponge rubber, which also comes in compounds (such as EPDM and silicone) that provide varying degrees of environmental resistance. The rubber’s hardness (durometer) and the profile’s shape are also important to consider.

Get Help with Foam Rubber vs. Sponge Rubber

Do you need low to medium volumes of custom gaskets? Ask Elasto Proxy about foam rubber vs. sponge rubber and for help with compound selection.

Once you’ve selected the right rubber material, we’ll use water jet cutting to convert sheets or extrusions. We also offer a choice of gasket bonding methods and can apply tape to your gaskets so that they arrive ready to install.

Ready to get started? Contact us.