Particle-filled silicones are elastomeric compounds that combine the advantages of silicone rubber with the electrical properties of metals. In Part 1 of this series, you’ll learn how shielding silicones support custom EMI gaskets.

Silicone rubber is a synthetic elastomer with useful physical and chemical properties over a wide range of temperatures. Silicones resist weathering, ultraviolet light, oxidation, moisture, and many chemicals. Polydimethylsiloxane (PDMS) compounds are also flexible, permeable, and non-irritating to human skin. With applications ranging from medical gaskets and oven seals to building expansion joints and lubricants, silicone rubbers are versatile materials.

Electrically Conductive Silicones

Yet silicone is not inherently electrically conductive. In fact, some silicones are such good electrical insulators that that they’re used with high-voltage equipment. The way that a silicone is compounded determines its specific properties, and compounders add various fillers, vulcanizing agents, and processing aids to the silicone gum and base. As a custom fabricator of high-quality rubber products, Elasto Proxy works with trusted suppliers, and can source materials that meet military program requirements.

EMI Shielding

For example, we can recommend shielding silicones that are electrically conductive and provide resistance to electromagnetic interference (EMI). As many product designers know, EMI shielding is critical in military applications such as touchscreen displays, satellite communications and unmanned systems. Particle-filled silicones for EMI shielding aren’t new, but some material buyers and product designers are still unfamiliar with the advantages of newer materials.

Custom Gaskets for Skeptical Designers

Typically, these “silicone skeptics” claim that all particle-filled elastomers are too hard, too prone to tearing, too expensive, and unable to meet performance requirements. Silicone rubbers have many desirable properties, the skeptics admit, but loading a high percentage of particle filler into the rubber results in unacceptable tradeoffs. Let’s examine their objections and see if they’re accurate. Then you can decide for yourself whether today’s particle-filled silicones can meet your military project requirements.

Material Hardness of Conductive Elastomers

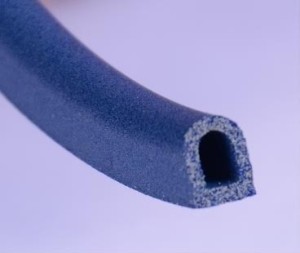

Seal designers worry that EMI gaskets made from harder materials won’t support compression or resist contaminants, chemicals, and water. That’s why Elasto Proxy recommends 30-durometer shielding silicones that are filled with either silver-plated aluminum or nickel-coated graphite particles. These ultra-soft silicones prove that conductive elastomers don’t have to be “too hard” for demanding applications such as military environments. In fact, these shielding silicones are softer than many other EMI materials.

Tensile Strength and Tear Resistance

If a particle-filled elastomer lacks sufficient tensile strength, cutting a small part with a thin cross-section may cause tearing. Naturally, gasket designers worry that these tears will cause the loss of a conductive seal and allow the entry of RF waves. That’s why Elasto Proxy recommends EMI shielding silicones that are reinforced with inner layer of conductive fabric or mesh. For example, one of the compounds we may recommend for your military application has a tensile strength of 950 psi and a Tear “B” ppi of 165.

Gasket Costs and Particle-Filled Silicones

Material properties aren’t all that engineers consider when analyzing EMI materials. Conductive silicones that contain silver-coated particles provide excellent shielding effectiveness, but silver is subject to volatility in the precious metals markets. If the price of silver rises dramatically, an EMI gasket that’s cost-effective today could result in cost overruns next year. That’s why Elasto Proxy may recommend shielding silicones that contain nickel-coated graphite particles instead of pure silver or silver-coated particles.

Material Performance of Shielding Silicones

How well do nickel-graphite shielding silicones perform? Simply put, the nickel-coated graphite silicones that Elasto Proxy recommends have the performance levels of silver-coated products. Standard MIL-DTL-83528 offerings and offsets also include Type B silver-plated aluminum with Qualified Products List (QPL) acknowledgement from the Defense Logistics Agency (DLA), and a shielding effectiveness test report. This information is available upon request, so please don’t hesitate to ask.