Rubber and plastic parts for robots are strong, lightweight, durable, and cost-effective. That’s not all.

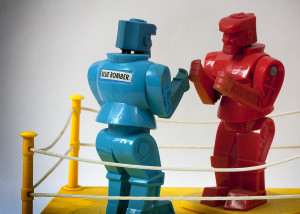

When you were a kid, did you play with Rock ‘Em Sock ‘Em Robots? Part toy and part game, this childhood classic features two boxers – both robots – that are mechanically manipulated by the players. The Red Rocker and the Blue Bomber have been hitting each other since the 1960s, but today’s version of this simulated boxing match features less metal and more plastic. Plastics are generally lighter and cheaper than metals, but is plastic really tough enough for robots – even toy ones? Is rubber right for robots, too?

The answers may surprise you.

Facts About Robots

First, however, it’s important to understand what robots are, what they do, and how demand for them is changing. In toys, games, and science fiction movies like The Iron Giant, robots are metal-filled machines that resemble humans in terms of shape, form, and physical movements. The toy boxers in Rock ‘Em Sock ‘Em Robots fit this mold, but that’s not what robots are all about.

Robots are machines that are designed to execute one or more tasks with speed and precision. Some are controlled by a human operator. Others are computer-controlled and fully-automated. Industrial robots are used in factories. Military and police robots are used in defense and security operations. Other types of robots, such as the iRobot Roomba vacuum cleaning robot, are available, too.

According to the International Federation of Robotics (IFR), global sales of all types of robots could reach nearly 23.9-million units between 2014 and 2017. Demand in all sectors is strong, but it’s soaring on the factory floor. From 2010 to 2017, the IFR reports, worldwide sales of industrial robots grew by nearly 50%. Advances in automation are driving this growth, but engineers analyze more than just sales forecasts.

Metal Armor and Rubber Tracks

For any type of product, material selection is an important decision consideration. Plastic is strong and lightweight, but it can’t withstand a blast from an explosive device. That’s why the bodies of military robots and police robots are made of metal. Product designers must account for material costs and total weight, but there’s no substitute for steel plating under combat-like conditions – or is there?

For any type of product, material selection is an important decision consideration. Plastic is strong and lightweight, but it can’t withstand a blast from an explosive device. That’s why the bodies of military robots and police robots are made of metal. Product designers must account for material costs and total weight, but there’s no substitute for steel plating under combat-like conditions – or is there?

Most tracked military vehicles even use tracks with metal plates. Thanks to advances in material science, however, replacement tracks made from specialized rubber compounds are available. In the case of police and military robots, polyurethane compounds can offer important advantages. According to QuinetiQ North America, maker of Talon robots, its rubber tracks are durable, lightweight, and flame-retardant.

Rubber tracks also provide better traction than metal plates, especially in off-road environments with rocks and mud. Plus, rubber won’t rust or corrode. In urban and suburban environments where police robots are typically used, rubber tracks won’t damage roadways either. Because rubber weighs less than metal, rubber tracks also support increased battery life, which can be crucial in extended operations.

Plastic Parts for Robots

The factory floor is a world apart from the battlefield or a crime scene. Industrial robots still need durable, long-lasting parts, but plastics can replace metal components in some applications. Depending on the robot’s weight, and on the required resistance to shock and impact, acrylic may be suitable for low-stress structural parts such as robot bodies. Polycarbonate is considerably stronger than acrylic, and PVC plastic is easy-to-process. Acetal resin, an engineering plastic, is both dense and strong.

The factory floor is a world apart from the battlefield or a crime scene. Industrial robots still need durable, long-lasting parts, but plastics can replace metal components in some applications. Depending on the robot’s weight, and on the required resistance to shock and impact, acrylic may be suitable for low-stress structural parts such as robot bodies. Polycarbonate is considerably stronger than acrylic, and PVC plastic is easy-to-process. Acetal resin, an engineering plastic, is both dense and strong.

Plastic parts aren’t right for every robotic application, but designers may still want to use polymers for cost-effective prototyping. For example, HDPE plastic sheets can be cut-to-size for an industrial robot’s base. Motors, servos, and other components can then be attached. By choosing a custom fabricator that uses water jet technology, you can source plastic parts for robots and avoid tooling charges.

As an experienced custom fabricator, Elasto Proxy serves a wide variety of industries. Examples include aerospace, defense, and mobile specialty vehicles. Do you need custom-fabricated rubber or plastic parts for robots? Elasto Proxy is ready to help. We specialize in low-to-medium volume quantities, and provide expert assistance with material selection and part design. Contact us for more information.