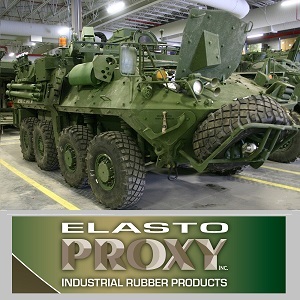

Rubber gaskets for military land systems provide sealing and insulation under battlefield conditions. These reliable rubber products are found in main battle tanks, light armored vehicles, armored fighting vehicles, weapons systems, and mine-resistant ambush protected (MRAP) vehicles. As a gasket fabricator that’s been serving the defense industry for over 25 years, Elasto Proxy supports military land systems from gasket design assistance and compound selection to custom fabrication, warehousing, and logistics.

Rubber gaskets for military land systems provide sealing and insulation under battlefield conditions. These reliable rubber products are found in main battle tanks, light armored vehicles, armored fighting vehicles, weapons systems, and mine-resistant ambush protected (MRAP) vehicles. As a gasket fabricator that’s been serving the defense industry for over 25 years, Elasto Proxy supports military land systems from gasket design assistance and compound selection to custom fabrication, warehousing, and logistics.

Design Assistance for Military Gaskets

Elasto Proxy uses SolidWorks, a powerful 3D CAD application, to validate your gasket designs and optimize them for cost and weight. With SolidWorks, our technical services team can simulate gasket compression, identify assembly and operational strains in rubber parts such as door seals, and analyze parameters such as compression set and tensile strength. By providing defense contractors with expert design assistance, Elasto Proxy serves as a force multiplier for your engineering department.

Military Compounds and Rubber Gaskets

Rubber gaskets for military land systems must be made of materials that meet requirements for media, temperature, application, and pressure. Media includes fuels, chemicals, and cleaning-type solutions. Temperature ratings cover minimum and maximum service temperatures. Application considerations include gasket installation procedures. Pressure is important to specify because of its relationship to seal failure. By helping to you choose the right military compounds, Elasto Proxy supports your design mission.

Custom Gasket Fabrication for Military Land Systems

Elasto Proxy specializes in the custom fabrication of low-to-medium volume quantities of rubber seals, gaskets, and insulation. At our manufacturing center near Montreal, Canada, we use water jet cutting to convert rolls, sheets, extrusions, and molded materials into custom sealing and insulation solutions. Unlike other parts fabrication methods, water jet cutting makes fast, precise cuts without long lead times or tooling charges. Our water jet machine cuts small parts and creates smooth joints, too.

Elasto Proxy specializes in the custom fabrication of low-to-medium volume quantities of rubber seals, gaskets, and insulation. At our manufacturing center near Montreal, Canada, we use water jet cutting to convert rolls, sheets, extrusions, and molded materials into custom sealing and insulation solutions. Unlike other parts fabrication methods, water jet cutting makes fast, precise cuts without long lead times or tooling charges. Our water jet machine cuts small parts and creates smooth joints, too.

Custom fabrication doesn’t stop with water jet cutting, however. To make rubber gaskets for military land systems, Elasto Proxy offers splicing and taping solutions. In addition to infrared film splicing, our production team can use cold bonding, C-press injection, and vulcanizing for joints, corners, and ends. Taping with a pressure-sensitive adhesive (PSA) or heat-activated taping system (HATS) keeps rubber profiles in place for temporary or permanent fastening in the field or on your assembly line.

Warehousing and Logistics for the Defense Supply Chain

When the availability of spare parts is critical, companies may worry about overdependence on a single supplier. That’s why the defense industry counts on Elasto Proxy to provide one-off rubber gaskets, or larger but limited quantities. Even when a military program ends, prime contractors and subcontractors know they can trust us to make spares and tackle old parts. Elasto Proxy can even store your rubber gaskets in our North American warehouses, and ship them to you on-demand.

When the availability of spare parts is critical, companies may worry about overdependence on a single supplier. That’s why the defense industry counts on Elasto Proxy to provide one-off rubber gaskets, or larger but limited quantities. Even when a military program ends, prime contractors and subcontractors know they can trust us to make spares and tackle old parts. Elasto Proxy can even store your rubber gaskets in our North American warehouses, and ship them to you on-demand.

Learn More about Rubber Gaskets for Military Land Systems

Elasto Proxy holds a Controlled Good Certificate (CGC) and is a trusted member of the defense supply chain. In Canada, the Controlled Good Program (CGP) is a registration and compliance program that regulates access to controlled goods, including International Traffic in Arms Regulations (ITAR) items. Elasto Proxy also work closely with trade groups such as the Canadian Association of Defense and Security Industries (CADSI), and regularly attends defense industry tradeshows such as CANSEC.

From February 19-23, 2017, Elasto Proxy will showcase its defense industry expertise at the International Defence Exhibition and Conference (IDEX) in Abu Dhabi, United Arab Emirates. If you’ll be at IDEX 2017, request a meeting with Elasto Proxy’s Sales Manager, Roberto Naccarato. You can also learn more about Elasto Proxy’s support for military land systems by downloading our case study about rubber hatch seals for military ground vehicles.