Engine compartment insulation keeps heat and noise in the engine bay from reaching a vehicle’s interior. It contains thermal insulation that reduces the transfer of heat from a higher-temperature object, the engine, to a lower-temperature one, the cabin. It also includes acoustic insulation that absorbs, blocks, and/or dampens sounds that would otherwise reach the cabin.

In most types of heavy equipment, the operator sits near the engine bay. Thermal insulation protects the cabin from high temperatures that can fatigue operators and damage onboard electronics. Acoustic insulation protects personnel from loud noises that can harm human hearing. It can also reduce sound-induced vibrations that damage mechanical structures.

Keep ready to learn more about engine bay insulation or contact Elasto Proxy to discuss your project.

Engine Compartment Insulation Materials

Elasto Proxy builds engine compartment insulation from sheets of thermal and acoustical materials and layers them together in a sandwich-style structure. Typically, this structure is between 1/2” (12.7mm) and 2” (50.8mm) thick.

Often, engine bay insulation has three layers.

- The top layer consists of aluminum facing or metalized Mylar that reflects radiant heat, withstands contact with water and engine oil, and can be reinforced for abrasion resistance.

- The middle layer includes a layer of hard rubber that stops loud engine sounds and a layer of acoustic foam for additional sound absorption.

- The bottom layer can use a pressure-sensitive adhesive (PSA) with a removable liner to speed installation. Taped insulation is easy-to-install and eliminates the health and safety concerns that are associated with adhesive spraying.

Typically, installers attach engine compartment insulation to the firewall, the part of the vehicle that separates the engine bay from the cab.

Engine Compartment Insulation Fabrication

Elasto Proxy uses lamination and cutting to fabricate engine bay insulation. Lamination bonds layers together. Water jet cutting converts laminated sheets into application-specific shapes. This precision-cutting technique also creates straight lines, rounded corners, and chamfers with 30° or 45° angles. The benefits include higher part quality, greater repeatability, higher material yields, and no tooling costs.

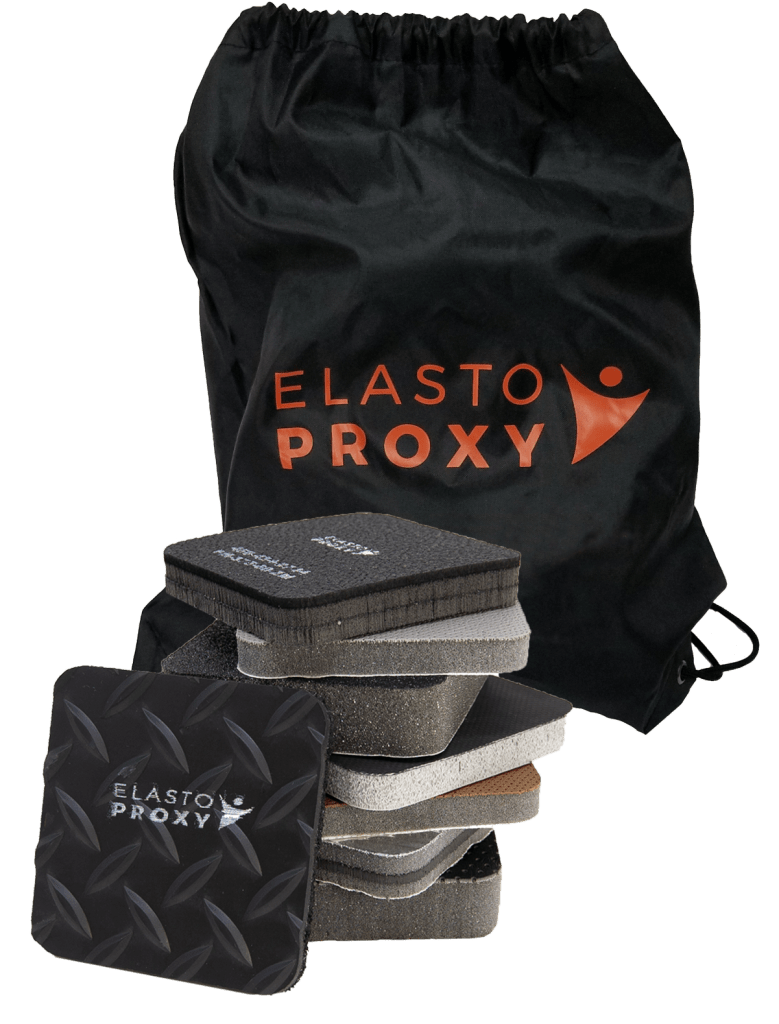

In addition to adhesive taping, Elasto Proxy offers added-value services like parts marking, kitting, and custom packaging. Parts that are marked with letters, numbers, or other identifying features can be custom-packaged into kits so that assemblers have everything they need in a single box. Instead of looking for 10 or 20 different SKUs in a warehouse, an installer can just open a box and get to work.

Three Engine Bay Insulation Products

Elasto Proxy can provide you with standard engine bay insulation that we cut to the shapes and sizes that you need. We can also create specialized solutions from custom combinations of materials.

There are three standard types of engine bay insulation.

- SH-500-58-ZMT is a three-layer composite that sandwiches a layer of silicone foam between a reinforced-fabric facing and a removable liner with a PSA adhesive. The facing material is black and smooth. All three materials provide strong resistance to chemicals, oils, and mildew. This product is suitable for applications with temperatures between -40°C and 150°C.

- SH-625-54-ZTBRA supports maximum sound attenuation over a broad frequency range. It sandwiches a vibration damper between acoustical foams and includes a metal foil facing that reflects radiant heat. For ease of installation, an adhesive-backed liner is used. SH-625-54-ZTBRA is dense, flexible, and characterized by high noise reduction.

- SH-2000-48-MEZT is a lightweight, fire-resistant melamine foam that can be combined with various facing materials and PSA liners. The open-cell melamine foam combines high-temperature resistance with superior sound-absorbing properties. Facing materials like aluminum foil can reflect radiant heat and provide chemical resistance.

Do you know which product you need? Request a quote from Elasto Proxy to get started.

Still not sure you have enough information? Ask for the Elasto Insulation Bag, a sackful of samples that includes SH-500-58-ZMT, SH-625-54-ZTBRA, and SH-2000-48-MEZT.